This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Aftertreatment Bracket 5419185 is a component designed for use in the aftertreatment systems of commercial trucks. Its purpose is to support and secure various elements within the aftertreatment system, contributing to the overall efficiency and effectiveness of emissions control technologies.

Basic Concepts of Aftertreatment Brackets

An aftertreatment bracket serves as a mounting solution for components within the aftertreatment system of a truck. Its function is to provide a stable and secure platform for these components, ensuring they remain in the correct position and orientation. This stability is vital for the proper operation of the aftertreatment system, which is designed to reduce harmful emissions from the truck’s exhaust. By securely holding components in place, aftertreatment brackets play a role in maintaining the integrity and performance of the emissions control system 1.

Role of the Aftertreatment Bracket 5419185 in Truck Operation

This Cummins part is positioned within the aftertreatment system to support specific components, ensuring they function as intended. It interacts with other system elements, such as sensors and emission control devices, by providing a stable mounting point. This stability allows for accurate readings and efficient operation of the aftertreatment system, contributing to the truck’s overall emissions performance.

Key Features of the Aftertreatment Bracket 5419185

The Aftertreatment Bracket 5419185 is characterized by its robust material composition, typically made from high-strength materials to withstand the harsh conditions of the aftertreatment environment. Its design includes features that enhance its functionality, such as precise mounting points and corrosion-resistant coatings. These features contribute to the bracket’s durability and reliability in supporting the aftertreatment system 2.

Benefits of Using the Aftertreatment Bracket 5419185

Utilizing this part offers several benefits, including improved emissions performance due to the secure mounting of aftertreatment components. Its durable construction ensures longevity, reducing the need for frequent replacements. Additionally, the bracket is designed for ease of installation, minimizing downtime during maintenance procedures.

Troubleshooting and Maintenance Suggestions

To ensure the longevity and optimal performance of the Aftertreatment Bracket 5419185, regular inspections are recommended. Look for signs of wear, corrosion, or damage that could affect its ability to securely hold aftertreatment components. Addressing issues promptly can prevent more significant problems within the aftertreatment system. Maintenance tips include keeping the bracket clean and free from debris that could interfere with its function 3.

Integration with Other Aftertreatment Components

The Aftertreatment Bracket 5419185 is designed to integrate seamlessly with other aftertreatment components, such as Diesel Particulate Filters (DPF), Selective Catalytic Reduction (SCR) systems, and Exhaust Gas Recirculation (EGR) systems. By providing a stable mounting solution, it ensures these components operate within their designed parameters, contributing to the overall effectiveness of the aftertreatment system in reducing emissions.

Environmental Impact and Emissions Reduction

Effective aftertreatment systems play a role in reducing the environmental impact of commercial trucks by significantly lowering emissions of pollutants. The Aftertreatment Bracket 5419185 contributes to this goal by ensuring the secure and proper operation of aftertreatment components. Its use helps trucks comply with environmental regulations, promoting cleaner air and reducing the carbon footprint of transportation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation in diesel engine technology and aftertreatment solutions, Cummins is committed to providing reliable and efficient products that meet the needs of its customers while also addressing environmental concerns. The company’s extensive product range and dedication to research and development underscore its position as a leader in the industry.

Compatibility of the Cummins Aftertreatment Bracket 5419185

This part is designed to support and secure various aftertreatment systems in a range of Cummins engines. It is essential for maintaining the structural integrity and operational efficiency of the aftertreatment system, ensuring compliance with emissions regulations.

QSK95 and CM2350 Engines

The Cummins Aftertreatment Bracket 5419185 is specifically engineered to fit seamlessly with the QSK95 and CM2350 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction equipment, mining machinery, and marine vessels. The bracket’s design ensures a precise fit, facilitating the installation and alignment of aftertreatment components, such as the Selective Catalytic Reduction (SCR) system and Diesel Exhaust Fluid (DEF) injector.

K113 Engine

Similarly, the K113 engine benefits from the use of the Cummins Aftertreatment Bracket 5419185. This engine is commonly utilized in agricultural and industrial applications, where durability and efficiency are paramount. The bracket’s compatibility with the K113 engine ensures that the aftertreatment system is securely mounted, reducing the risk of mechanical failure and enhancing the overall performance of the engine.

Grouping by Application

The Cummins Aftertreatment Bracket 5419185 is versatile and can be grouped by the type of application where these engines are predominantly used. For instance, in heavy-duty construction and mining equipment, the bracket’s robust design helps withstand the harsh operating conditions, ensuring longevity and reliability. In marine applications, the bracket’s corrosion-resistant properties are crucial for maintaining performance in challenging environments.

In agricultural machinery, the bracket’s precision fit is essential for the efficient operation of the aftertreatment system, which is critical for meeting stringent emissions standards. The bracket’s design also facilitates easier maintenance and repair, reducing downtime and operational costs.

Role of the Aftertreatment Bracket 5419185 in Engine Systems

This part is an essential component in the integration and secure mounting of aftertreatment devices within engine systems. This bracket facilitates the proper alignment and attachment of the aftertreatment device, ensuring it is correctly positioned relative to other engine components.

When installed, the Aftertreatment Bracket supports the aftertreatment device, which typically includes components such as the Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) system, and other emission control devices. This secure mounting is vital for the effective operation of these systems, as it ensures that exhaust gases flow through the aftertreatment device as designed, maximizing its efficiency in reducing emissions.

Additionally, the bracket helps maintain the structural integrity of the aftertreatment system under various operating conditions, including vibrations and thermal expansions that occur during engine operation. This stability is important for the longevity and performance of the aftertreatment device, preventing potential damage or misalignment that could compromise its function.

Conclusion

In summary, the Aftertreatment Bracket 5419185 plays a significant role in the overall effectiveness and durability of the aftertreatment system within engine configurations. Its robust design, compatibility with various Cummins engines, and contribution to emissions reduction underscore its importance in modern commercial truck operations.

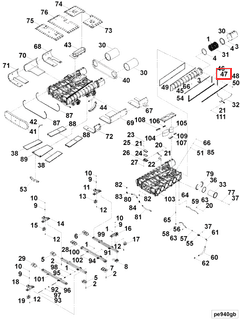

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.