This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

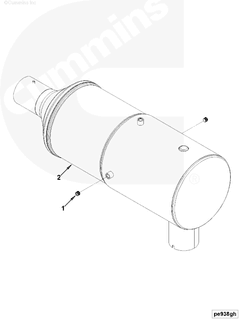

The Cummins 4353961 Aftertreatment Device is a component designed to enhance the emissions control system of heavy-duty trucks. Its purpose is to reduce the levels of harmful pollutants emitted by diesel engines, aligning with stringent environmental regulations. This device is significant in the context of heavy-duty truck emissions control, as it helps manufacturers and operators meet regulatory standards while improving air quality 1.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems installed in the exhaust pathways of vehicles to reduce the emissions of pollutants. They play a role in emissions control by capturing and converting harmful substances into less harmful ones before they are released into the atmosphere. In heavy-duty trucks, these devices integrate into the exhaust system, working in conjunction with the engine to minimize the environmental impact of diesel combustion 2.

Purpose of the Cummins 4353961 Aftertreatment Device

The Cummins 4353961 Aftertreatment Device is specifically designed to reduce emissions from heavy-duty trucks. It functions by processing exhaust gases to remove pollutants such as nitrogen oxides (NOx) and particulate matter (PM). This device aids in complying with environmental regulations by ensuring that the emissions from trucks are within the permissible limits set by authorities 3.

Key Features

The Cummins 4353961 Aftertreatment Device boasts several primary features that enhance its performance and durability. Its design incorporates advanced materials that resist corrosion and withstand high temperatures. Technological innovations within the device, such as precise sensor integration and control algorithms, ensure efficient operation and long-term reliability 4.

Benefits

The advantages provided by the Cummins 4353961 Aftertreatment Device include improved emissions performance, which is crucial for meeting regulatory standards. Additionally, the device may contribute to potential fuel savings by optimizing the exhaust process. Its compliance with regulatory standards ensures that trucks equipped with this device can operate without legal impediments related to emissions.

Installation and Integration

Installing the Cummins 4353961 Aftertreatment Device involves several steps and considerations to ensure compatibility with various engine types and exhaust systems. Proper installation is crucial for the device to function effectively and integrate seamlessly into the truck’s emissions control system.

Operational Efficiency

The Cummins 4353961 Aftertreatment Device contributes to the overall efficiency of the truck by optimizing the exhaust process. While its primary function is emissions reduction, it may also have a positive impact on engine performance and fuel economy by ensuring that the exhaust system operates at peak efficiency.

Maintenance and Troubleshooting

Maintaining the Cummins 4353961 Aftertreatment Device is important for ensuring optimal performance and longevity. Regular inspections and adherence to manufacturer guidelines can prevent common issues. Troubleshooting tips, such as monitoring sensor readings and addressing unusual noises or performance drops, can help maintain the device’s effectiveness.

Environmental Impact

The environmental benefits provided by the Cummins 4353961 Aftertreatment Device include significant reductions in harmful emissions. By capturing and converting pollutants, this device contributes to improved air quality and helps mitigate the environmental impact of diesel-powered heavy-duty trucks.

Technological Advancements

The Cummins 4353961 Aftertreatment Device incorporates several technological innovations. These include the use of advanced materials for durability, sensor integration for precise monitoring, and control algorithms that optimize the device’s performance. These advancements ensure that the device remains at the forefront of emissions control technology.

Cummins Overview

Cummins Inc. is a leader in diesel engine technology, with a long history of innovation and expertise. The company is committed to developing advanced emissions control solutions, including the Cummins 4353961 Aftertreatment Device. This commitment reflects Cummins’ dedication to environmental stewardship and technological advancement in the heavy-duty truck industry.

Cummins Aftertreatment Device 4353961 Compatibility

The Cummins Aftertreatment Device part number 4353961 is designed to integrate seamlessly with specific Cummins engine models. This part is crucial for maintaining the performance and compliance of the engines with environmental regulations.

QSB4.5 CM2250 EC and QSB6.7 CM2250

The 4353961 Aftertreatment Device is compatible with the QSB4.5 CM2250 EC and QSB6.7 CM2250 engines. These engines are part of the Cummins QSB series, known for their reliability and efficiency in various applications. The integration of the aftertreatment device ensures that the engines meet stringent emission standards, enhancing their operational efficiency and reducing environmental impact.

The compatibility of the 4353961 part with these engines is achieved through precise engineering and design, ensuring that it fits perfectly within the engine’s architecture. This compatibility is essential for maintaining the overall performance and longevity of the engines.

By using the 4353961 Aftertreatment Device, operators can be assured of improved engine performance, reduced maintenance costs, and adherence to regulatory requirements. This part is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance the functionality of their engines.

Role of Part 4353961 Aftertreatment Device in Engine Systems

The aftertreatment device, specifically part 4353961, is an integral component in modern engine systems, designed to reduce emissions and ensure compliance with environmental regulations. This device works in conjunction with several key components to enhance the overall efficiency and environmental performance of the engine.

Integration with the Exhaust System

The aftertreatment device is typically positioned within the exhaust system, downstream of the engine. It interacts closely with the exhaust manifold, where it receives the raw exhaust gases produced by the engine. The device then processes these gases to reduce harmful emissions before they are released into the atmosphere.

Interaction with the Diesel Particulate Filter (DPF)

In diesel engine systems, part 4353961 often works alongside the Diesel Particulate Filter (DPF). The DPF captures particulate matter from the exhaust gases, while the aftertreatment device further treats the gases to reduce nitrogen oxides (NOx) and other pollutants. This synergy ensures a comprehensive approach to emission control.

Coordination with the Selective Catalytic Reduction (SCR) System

For engines equipped with a Selective Catalytic Reduction (SCR) system, the aftertreatment device plays a supportive role. The SCR system injects a urea-based solution into the exhaust stream, which reacts with the NOx to form harmless nitrogen and water. The aftertreatment device enhances this process by ensuring that the exhaust gases are at an optimal temperature and composition for the SCR reaction to occur efficiently.

Role in the Exhaust Gas Recirculation (EGR) System

In engines with an Exhaust Gas Recirculation (EGR) system, the aftertreatment device helps manage the recirculated exhaust gases. The EGR system redirects a portion of the exhaust gas back into the engine’s intake to reduce NOx formation. The aftertreatment device ensures that the recirculated gases do not introduce additional pollutants, maintaining the overall emission reduction effectiveness of the system.

Contribution to the Oxygen Sensor Network

The aftertreatment device also interacts with the engine’s oxygen sensor network. These sensors monitor the oxygen levels in the exhaust gases, providing feedback to the engine control unit (ECU). The aftertreatment device ensures that the exhaust gases are treated effectively, allowing the oxygen sensors to provide accurate data for the ECU to make necessary adjustments to the engine’s operation.

Enhancement of the Turbocharger Efficiency

In turbocharged engines, the aftertreatment device contributes to the overall efficiency of the turbocharger. By ensuring that the exhaust gases are clean and at an optimal temperature, the device helps maintain the turbocharger’s performance, allowing it to compress the intake air more effectively and improve engine power and fuel efficiency.

Support for the Engine Control Unit (ECU)

Finally, the aftertreatment device supports the Engine Control Unit (ECU) by providing a treated exhaust stream that aligns with the ECU’s emission control strategies. The ECU relies on the aftertreatment device to ensure that the engine operates within the desired emission parameters, facilitating smooth and efficient engine performance.

Conclusion

The Cummins 4353961 Aftertreatment Device is a critical component in the emissions control system of heavy-duty trucks. It enhances the efficiency and environmental performance of the engine by reducing harmful emissions and ensuring compliance with regulatory standards. Through its integration with various engine systems and components, this device plays a vital role in modern diesel engine technology, reflecting Cummins’ commitment to innovation and environmental stewardship.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.