This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

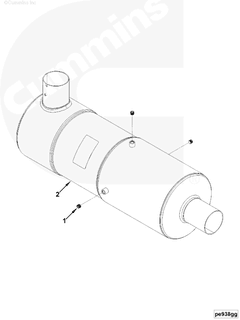

The Cummins 4353962 Aftertreatment Device is a component designed for use in commercial trucks. Its purpose is to reduce emissions and enhance engine performance, ensuring that vehicles comply with environmental regulations. This device is integral to the operation of modern commercial trucks, playing a significant role in maintaining efficient and clean engine performance 1.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems installed in the exhaust pathways of vehicles to reduce the levels of harmful emissions released into the atmosphere. These devices work by filtering out pollutants and converting them into less harmful substances before they exit the tailpipe. In the context of a truck, aftertreatment devices are essential for integrating into the exhaust system to ensure that the engine operates within permissible emission standards 2.

Purpose of the Cummins 4353962 Aftertreatment Device

The Cummins 4353962 Aftertreatment Device specifically aims to reduce emissions by processing exhaust gases to remove pollutants such as nitrogen oxides (NOx) and particulate matter (PM). This device enhances engine performance by ensuring that the engine operates efficiently while meeting stringent environmental regulations. Its role is vital in the overall emission control strategy of commercial trucks 3.

Key Features

The 4353962 Aftertreatment Device is characterized by several primary features that enhance its performance and durability. Its design incorporates advanced materials that resist corrosion and withstand high temperatures. Technological advancements such as improved catalyst formulations and smart monitoring systems are integrated into this device to optimize its function and longevity.

Benefits

Utilizing the Cummins 4353962 Aftertreatment Device offers several advantages. These include improved fuel efficiency due to optimized engine performance, reduced maintenance costs thanks to its durable construction, and enhanced engine longevity as a result of effective emission control. These benefits contribute to the overall efficiency and reliability of commercial trucks.

Integration with Other Systems

The 4353962 Aftertreatment Device interacts with various components of the truck’s exhaust and engine system. It works in conjunction with sensors, control modules, and other aftertreatment components to monitor and adjust the emission control process. This integration ensures that the device operates seamlessly within the truck’s overall system, contributing to efficient emission reduction.

Maintenance and Troubleshooting

Regular maintenance practices for the 4353962 Aftertreatment Device include periodic inspections and cleaning to ensure optimal performance. Common issues that may arise include catalyst degradation or sensor malfunctions. Troubleshooting tips involve checking for error codes, inspecting physical components for damage, and ensuring that all connections are secure and functioning correctly.

Environmental Impact

The environmental benefits provided by the 4353962 Aftertreatment Device are significant. By reducing harmful emissions such as NOx and PM, this device contributes to cleaner air quality. Its effective emission control helps mitigate the environmental impact of commercial trucks, aligning with global efforts to reduce air pollution and improve public health.

Technological Advancements

The Cummins 4353962 Aftertreatment Device incorporates several technological innovations. These include the use of advanced materials that enhance durability, improved catalyst formulations that increase efficiency, and smart monitoring systems that provide real-time data on device performance. These advancements ensure that the device remains at the forefront of emission control technology.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to quality, particularly in the development of aftertreatment devices and other engine components. Cummins’ dedication to advancing technology and maintaining high standards of manufacturing is evident in their product lineup, including the 4353962 Aftertreatment Device.

Compatibility

The Cummins Aftertreatment Device part number 4353962 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and compliance with emission standards. This part is specifically engineered to fit the following engines:

- QSB4.5 CM2250 EC

- QSB6.7 CM2250

These engines, part of the Cummins QSB series, are known for their robust design and efficiency, making them suitable for various industrial and commercial applications. The Aftertreatment Device 4353962 is tailored to work with these engines, providing essential functions such as exhaust gas treatment and emissions control.

By ensuring compatibility with both the QSB4.5 CM2250 EC and QSB6.7 CM2250 engines, Cummins guarantees that the Aftertreatment Device 4353962 will effectively support the operational needs of these engines, enhancing their overall performance and reliability.

Role of Aftertreatment Device (Part 4353962) in Engine Systems

The aftertreatment device, specifically part 4353962, is integral to the operation of modern engine systems, ensuring they meet stringent emissions regulations while maintaining performance efficiency. This component works in conjunction with several other engine components to reduce harmful emissions and improve overall engine functionality.

Integration with the Exhaust System

The aftertreatment device is typically positioned downstream of the turbocharger and the exhaust manifold. Its primary function is to treat the exhaust gases before they are released into the atmosphere. By doing so, it significantly reduces the levels of nitrogen oxides (NOx) and particulate matter (PM), which are common pollutants emitted by diesel engines.

Interaction with the Diesel Particulate Filter (DPF)

One of the key components the aftertreatment device interacts with is the Diesel Particulate Filter (DPF). The DPF captures soot and other particulates from the exhaust gases. The aftertreatment device enhances this process by ensuring that the captured particles are effectively managed and reduced, preventing the DPF from becoming clogged and ensuring it operates efficiently over time.

Coordination with the Selective Catalytic Reduction (SCR) System

The aftertreatment device also plays a significant role in the Selective Catalytic Reduction (SCR) system. The SCR system injects a urea-based solution into the exhaust stream, which reacts with the NOx to convert them into harmless nitrogen and water vapor. The aftertreatment device ensures that this reaction is optimized, maximizing the efficiency of the SCR system and minimizing the amount of unreacted urea that could otherwise escape into the environment.

Synergy with the Engine Control Unit (ECU)

The aftertreatment device communicates with the Engine Control Unit (ECU) to monitor and adjust the exhaust treatment process in real-time. The ECU uses data from various sensors to make necessary adjustments to the fuel injection timing, exhaust gas recirculation (EGR) rates, and urea injection quantities. This dynamic interaction ensures that the aftertreatment process is always aligned with the engine’s operating conditions, enhancing both performance and emissions compliance.

Enhancement of the Overall Engine Performance

By effectively managing and reducing emissions, the aftertreatment device allows the engine to operate more cleanly and efficiently. This not only helps in meeting regulatory standards but also contributes to the longevity and reliability of the engine components. The reduced levels of harmful emissions also mean less wear and tear on the engine, leading to potentially lower maintenance costs and improved overall performance.

Conclusion

The Cummins 4353962 Aftertreatment Device is a critical component in the quest for cleaner and more efficient engine performance in commercial trucks. Through its advanced features, integration with other systems, and technological innovations, this part ensures that engines not only comply with stringent emission regulations but also operate at peak efficiency. The environmental and economic benefits of using this device are substantial, making it a valuable asset in the ongoing efforts to reduce the environmental impact of commercial vehicles.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.