This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

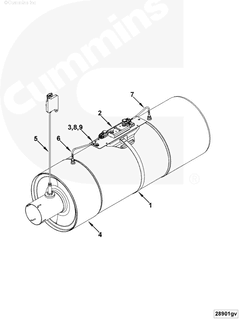

The Cummins 4354210 Aftertreatment Device is a component designed to enhance the emissions control system in commercial trucks. Its purpose is to reduce harmful emissions produced by diesel engines, contributing to cleaner air and compliance with environmental regulations. This device is significant in the context of commercial truck operations as it helps maintain environmental standards while ensuring the efficient operation of diesel engines.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems installed in diesel engines to reduce the emissions of pollutants such as nitrogen oxides (NOx) and particulate matter (PM). These devices work by treating the exhaust gases after they leave the engine, before they are released into the atmosphere. The general function of aftertreatment devices is to convert harmful emissions into less harmful substances, thereby contributing to emissions reduction and environmental protection 1.

Purpose of the Cummins 4354210 Aftertreatment Device

The Cummins 4354210 Aftertreatment Device plays a specific role in the operation of a truck by integrating into the emissions control system. It is designed to further reduce emissions that have already been partially treated by other components such as the Diesel Particulate Filter (DPF) and the Selective Catalytic Reduction (SCR) system. This device ensures that the truck meets stringent emissions standards by targeting specific pollutants and enhancing the overall efficiency of the emissions control system 2.

Key Features

The Cummins 4354210 Aftertreatment Device features several design elements and technological innovations that enhance its performance. These include the use of high-quality materials resistant to the harsh conditions of diesel exhaust, advanced catalytic coatings that facilitate chemical reactions, and a compact design that allows for easy integration into the truck’s exhaust system. These features contribute to the device’s effectiveness in reducing emissions and ensuring long-term durability 3.

Benefits

The Cummins 4354210 Aftertreatment Device offers several benefits, including improved emissions performance, compliance with environmental regulations, and potential fuel efficiency gains. By reducing harmful emissions, the device helps protect the environment and public health. Additionally, it assists truck operators in meeting regulatory requirements, avoiding fines, and maintaining a positive environmental image. The device may also contribute to improved fuel efficiency by optimizing the emissions control process 4.

Operational Mechanism

The Cummins 4354210 Aftertreatment Device operates through a combination of chemical and physical processes to reduce emissions. It utilizes catalytic reactions to convert NOx into nitrogen and water vapor, significantly lowering the levels of these pollutants in the exhaust. The device also works in conjunction with other emissions control components to ensure comprehensive treatment of the exhaust gases, resulting in cleaner emissions 5.

Integration with Other Systems

The Cummins 4354210 Aftertreatment Device integrates seamlessly with other components of the truck’s emissions control system, such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. It works in harmony with these systems to provide a comprehensive solution for emissions reduction. The device is designed to complement the functions of the DPF and SCR, ensuring that the truck’s exhaust meets the required emissions standards 6.

Maintenance and Troubleshooting

Maintaining the Cummins 4354210 Aftertreatment Device involves regular inspection procedures to ensure its optimal performance. Common issues may include catalyst deactivation or blockages in the exhaust system, which can be addressed through routine maintenance checks and cleaning. Troubleshooting tips include monitoring the device’s performance through diagnostic tools and addressing any anomalies promptly to prevent further complications 7.

Regulatory Compliance

The Cummins 4354210 Aftertreatment Device plays a role in helping trucks meet various emissions regulations and standards. By reducing harmful emissions, the device ensures that trucks comply with environmental laws, avoiding penalties and contributing to a cleaner environment. It is designed to meet the requirements of regulatory bodies, providing truck operators with a reliable solution for emissions control 8.

Environmental Impact

The use of the Cummins 4354210 Aftertreatment Device results in significant environmental benefits, including reductions in harmful emissions such as NOx and PM. By converting these pollutants into less harmful substances, the device contributes to improved air quality and reduced environmental impact. Its role in emissions reduction is crucial for sustainable truck operations and environmental protection 9.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a long history of innovation and excellence in the industry. The company plays a significant role in the development and manufacturing of diesel engine components and aftertreatment systems, providing solutions that enhance engine performance, efficiency, and environmental compliance. Cummins’ commitment to quality and innovation is evident in its wide range of products, including the Cummins 4354210 Aftertreatment Device 10.

Role of Part 4354210 Aftertreatment Device in Engine Systems

The aftertreatment device, specifically part 4354210, is integral to the overall functionality and efficiency of modern engine systems. It works in conjunction with several key components to ensure that emissions are minimized and the engine operates within regulatory standards.

Integration with the Exhaust System

Part 4354210 is typically positioned downstream of the turbocharger and the exhaust manifold. Its primary role here is to treat the exhaust gases before they are expelled into the atmosphere. This device interacts closely with the exhaust gas recirculation (EGR) system, which recirculates a portion of the exhaust gas back into the intake manifold to reduce nitrogen oxides (NOx) formation 11.

Interaction with the Diesel Particulate Filter (DPF)

In diesel engine systems, the aftertreatment device often includes or works alongside a Diesel Particulate Filter (DPF). The DPF captures soot and other particulate matter from the exhaust gases. Part 4354210 may incorporate a catalyst that aids in the oxidation of these particulates, facilitating their removal during the regeneration process of the DPF 12.

Coordination with the Selective Catalytic Reduction (SCR) System

For engines equipped with a Selective Catalytic Reduction (SCR) system, part 4354210 plays a significant role in the reduction of NOx emissions. The SCR system injects a urea-based solution into the exhaust stream, which reacts with the NOx over a catalyst to form harmless nitrogen and water vapor. The aftertreatment device ensures that this reaction is optimized, enhancing the overall efficiency of the SCR system 13.

Synergy with the Oxygen Sensors

Oxygen sensors placed upstream and downstream of the aftertreatment device provide critical data to the engine control unit (ECU). These sensors help monitor the efficiency of the aftertreatment processes, allowing the ECU to make real-time adjustments to fuel injection and air-fuel ratio to maintain optimal performance and emissions control 14.

Contribution to the Overall Engine Performance

By effectively managing and reducing harmful emissions, part 4354210 contributes to the engine’s overall performance. It ensures that the engine complies with environmental regulations while maintaining power output and fuel efficiency. The device also helps in prolonging the life of other engine components by reducing the amount of unburnt fuel and particulate matter that could otherwise cause damage 15.

Conclusion

The Cummins 4354210 Aftertreatment Device is a critical component in the emissions control system of commercial trucks. It enhances the efficiency of the emissions control process, ensures compliance with environmental regulations, and contributes to improved air quality. By integrating seamlessly with other emissions control components and offering significant environmental benefits, this Cummins part plays a vital role in sustainable truck operations and environmental protection.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504188, KTAA19 K131 G.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504188, KTAA19 K131 G.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504188, KTAA19 K131 G.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.