This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

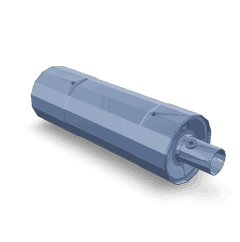

The Cummins 4354225 Aftertreatment Device is a component designed for use in commercial trucks. Its purpose is to reduce emissions and ensure compliance with environmental regulations. This device integrates into the exhaust system and works alongside other components to minimize the environmental impact of truck emissions.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems installed in the exhaust pathways of vehicles to reduce the levels of harmful emissions released into the atmosphere. These devices work by filtering out pollutants and converting them into less harmful substances before they exit the tailpipe. In the context of a truck, aftertreatment devices are essential for meeting stringent emissions standards and for promoting cleaner air quality. They are typically composed of several components, including filters, catalysts, and sensors, all working in concert to clean the exhaust gases produced by the engine 1.

Purpose of the Cummins 4354225 Aftertreatment Device

The Cummins 4354225 Aftertreatment Device is specifically engineered to reduce emissions from commercial trucks. It ensures that the truck meets environmental regulations by filtering out pollutants such as nitrogen oxides (NOx) and particulate matter (PM). Additionally, this device contributes to enhancing engine performance by maintaining efficient exhaust flow and supporting the overall efficiency of the truck’s powertrain.

Key Features

The Cummins 4354225 Aftertreatment Device is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. It incorporates technological advancements such as advanced sensors and automated regeneration processes. These features allow the device to operate efficiently under a variety of driving conditions and contribute to its effectiveness in reducing emissions.

Benefits

The advantages of the Cummins 4354225 Aftertreatment Device include improved fuel efficiency, as it allows the engine to operate more cleanly and efficiently. It also contributes to reduced maintenance costs due to its durable construction and the integration of self-cleaning mechanisms. Furthermore, by ensuring cleaner emissions, the device helps in extending the engine’s life by reducing the wear and tear caused by harmful emissions.

Installation Process

Installing the Cummins 4354225 Aftertreatment Device requires adherence to a step-by-step process to ensure proper integration with the truck’s existing systems. Prerequisites include ensuring the truck’s exhaust system is clean and free of obstructions. The installation may require specific tools and should be performed by trained professionals to guarantee compatibility and optimal performance.

Troubleshooting Common Issues

Frequent problems with aftertreatment devices can include clogging, sensor malfunctions, and issues with the regeneration process. Identifying these problems early can prevent more significant issues down the line. Solutions may involve cleaning the device, replacing faulty sensors, or adjusting the regeneration settings to maintain optimal performance.

Maintenance Tips

To ensure the longevity and efficiency of the Cummins 4354225 Aftertreatment Device, regular maintenance is recommended. This includes performing regular checks for signs of wear or damage, cleaning the device as necessary, and following the manufacturer’s guidelines for maintenance intervals. Professional service should be sought for complex issues or when the device’s performance seems compromised.

Environmental Impact

The Cummins 4354225 Aftertreatment Device plays a role in promoting sustainable trucking operations by significantly reducing the levels of harmful emissions released into the atmosphere. Its effective filtration and conversion of pollutants contribute to lower overall emissions from commercial trucks, supporting efforts to improve air quality and reduce the environmental footprint of the trucking industry.

Technological Innovations

The Cummins 4354225 Aftertreatment Device incorporates several technological innovations, such as advanced sensors for real-time monitoring of emissions, automated regeneration processes to clean the device without manual intervention, and integration with engine management systems for optimized performance. These technologies enhance the device’s effectiveness in reducing emissions and ensuring compliance with environmental regulations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftertreatment systems. With a history of innovation and a strong commitment to sustainability, Cummins plays a significant role in the commercial truck industry by providing reliable and efficient power solutions that meet the demands of modern transportation while minimizing environmental impact 2.

Role of the Cummins 4354225 Aftertreatment Device in Engine Systems

The Cummins 4354225 Aftertreatment Device is integral to the operation of modern engine systems, ensuring they meet stringent emissions regulations while maintaining performance efficiency. This component works in concert with several other systems and components to achieve optimal results.

Integration with the Exhaust System

The aftertreatment device is positioned downstream of the engine’s exhaust manifold. Its primary function is to process the exhaust gases before they are released into the atmosphere. It interfaces directly with the exhaust pipe, catalytic converter, and diesel particulate filter (DPF), if present. This placement allows it to effectively reduce harmful emissions such as nitrogen oxides (NOx) and particulate matter (PM).

Interaction with the Engine Control Unit (ECU)

The ECU plays a significant role in monitoring and controlling the aftertreatment device. Sensors within the exhaust system, such as oxygen sensors and NOx sensors, provide real-time data to the ECU. The ECU uses this information to adjust the operation of the aftertreatment device, ensuring it functions within optimal parameters. This might involve modifying the fuel injection timing or the exhaust gas recirculation (EGR) rate to enhance the efficiency of the aftertreatment processes.

Coordination with the Selective Catalytic Reduction (SCR) System

In engines equipped with SCR technology, the aftertreatment device works in tandem with the SCR system. The SCR system injects a urea-based solution, commonly known as Diesel Exhaust Fluid (DEF), into the exhaust stream. The aftertreatment device then catalyzes a reaction that converts NOx into harmless nitrogen (N2) and water (H2O). The effectiveness of this process relies on the precise control and monitoring by the aftertreatment device.

Support from the Diesel Oxidation Catalyst (DOC)

Upstream of the aftertreatment device, the Diesel Oxidation Catalyst (DOC) plays a supportive role. The DOC reduces hydrocarbons (HC) and carbon monoxide (CO) in the exhaust gases. By pre-treating the exhaust, the DOC enhances the overall efficiency of the aftertreatment device, allowing it to focus more effectively on NOx reduction.

Role in the Regeneration Process

For engines with a DPF, the aftertreatment device is involved in the regeneration process. During regeneration, accumulated particulate matter in the DPF is burned off. The aftertreatment device helps manage the temperature and chemical reactions necessary for effective regeneration, ensuring the DPF remains clean and functional.

Contribution to Overall Engine Performance

Beyond emissions control, the aftertreatment device contributes to the engine’s overall performance. By ensuring that exhaust gases are properly treated, it helps maintain the engine’s efficiency and longevity. Additionally, it plays a role in reducing the engine’s carbon footprint, aligning with global efforts to minimize environmental impact.

Conclusion

In summary, the Cummins 4354225 Aftertreatment Device is a multifaceted component that interacts with various engine systems to enhance performance, ensure compliance with emissions standards, and contribute to environmental sustainability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.