This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

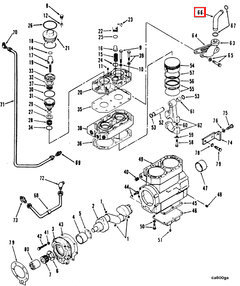

The Compressor Air Inlet Tube 206086, manufactured by Cummins, is a critical component in the air management system of heavy-duty trucks. This part ensures efficient operation of the compressor, contributing to the vehicle’s overall performance and reliability.

Basic Concepts

Compressor air inlet tubes are designed to facilitate the flow of air into the compressor, a vital component of the truck’s air management system. This system regulates the air supply to various engine parts, ensuring optimal performance and efficiency. The Compressor Air Inlet Tube specifically channels air to the compressor, where it is pressurized before being distributed to other engine components 1.

Purpose and Function

The Compressor Air Inlet Tube 206086 is designed to deliver a steady and efficient flow of air to the compressor. By ensuring a consistent air supply, it helps maintain the compressor’s performance, which in turn supports the engine’s overall efficiency. The tube’s design minimizes turbulence and resistance, allowing for smooth air flow and reducing the workload on the compressor 2.

Key Features

This Cummins part is constructed from durable materials that can withstand the harsh conditions often encountered in heavy-duty truck environments. Its design includes features that enhance air flow efficiency, such as a smooth interior surface and precise dimensions. Additionally, the tube may incorporate elements that reduce noise and vibration, contributing to a quieter and more stable operation 3.

Benefits

The use of the Compressor Air Inlet Tube 206086 can lead to improved air flow efficiency and enhanced compressor performance. These factors contribute to better overall engine performance and potentially increased fuel efficiency. Moreover, the durable construction of the tube supports the reliability of the truck’s air management system, reducing the likelihood of failures and maintenance issues 4.

Installation and Compatibility

Proper installation of the Compressor Air Inlet Tube 206086 is important for ensuring optimal performance and compatibility with Cummins engines. Installation procedures should follow manufacturer guidelines to ensure a secure fit and proper alignment. Specific requirements may include torque specifications for fasteners and alignment checks to prevent air leaks or restrictions 5.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Air Inlet Tube 206086 involves inspection for signs of wear, damage, or contamination. Cleaning the tube to remove any debris that could obstruct air flow is also recommended. Troubleshooting common issues such as leaks or blockages may involve checking connections, inspecting for cracks or holes, and ensuring that the tube is free from obstructions 6.

Performance Optimization

To maximize the performance of the Compressor Air Inlet Tube 206086, it is important to maintain optimal air flow and address any sources of restriction or contamination. Regular inspections and cleaning can help prevent issues that could affect air flow efficiency. Additionally, staying informed about advancements in air management technology may provide opportunities for further optimization 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s product offerings include a wide range of engines, components, and technologies designed to meet the diverse needs of its customers 8.

Conclusion

The Compressor Air Inlet Tube 206086 by Cummins is a vital component in the air management system of heavy-duty trucks. Its design and construction ensure efficient air flow to the compressor, contributing to the engine’s overall performance and reliability. Proper installation, maintenance, and optimization of this part are essential for maximizing its benefits and ensuring the longevity of the truck’s air management system.

-

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Hiereth, Hermann, Peter Prenninger, and Klaus W Drexl. Charging the Internal Combustion Engine. Springer, 2010.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Cummins Inc. Service Manual (5504360). B5.6 CM2670 B152B.

↩ -

Cummins Inc. Service Manual (5504360). B5.6 CM2670 B152B.

↩ -

Cummins Inc. Service Manual (5504360). B5.6 CM2670 B152B.

↩ -

Cummins Inc. Service Manual (5504360). B5.6 CM2670 B152B.

↩ -

Cummins Inc. Service Manual (5504360). B5.6 CM2670 B152B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.