This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

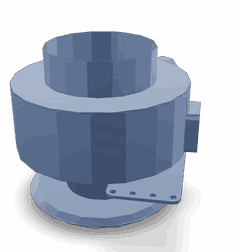

The Cummins 2870492 Air Fuel Mixer is a component designed to enhance the performance of heavy-duty trucks by optimizing the air-fuel mixture for combustion. This part is integral to the efficient operation of the engine, ensuring that the right proportions of air and fuel are mixed before entering the combustion chamber.

Basic Concepts of Air Fuel Mixers

An air fuel mixer is a device that combines air and fuel in precise ratios to create an optimal mixture for combustion. This mixture is crucial for the efficient operation of an internal combustion engine. The principles of air-fuel ratio management involve maintaining the correct balance to ensure complete combustion, which leads to better engine performance, fuel efficiency, and reduced emissions 1.

Purpose of the Cummins 2870492 Air Fuel Mixer

The Cummins 2870492 Air Fuel Mixer plays a role in the operation of a truck by optimizing the air-fuel mixture for combustion. This optimization ensures that the engine operates efficiently, with the right balance of air and fuel to achieve complete combustion. This results in improved engine performance, better fuel economy, and lower emissions.

Key Features

The Cummins 2870492 incorporates several key features that enhance its functionality. Its design is engineered to provide precise air-fuel mixing, ensuring optimal combustion. The materials used in its construction are durable and resistant to the high temperatures and pressures within the engine. Additionally, technological advancements in the mixer allow for more accurate air-fuel ratio management, contributing to overall engine efficiency.

Benefits of Using the Cummins 2870492 Air Fuel Mixer

The advantages provided by the Cummins 2870492 include improved engine performance, enhanced fuel efficiency, and reductions in emissions. By ensuring an optimal air-fuel mixture, the mixer contributes to more complete combustion, which leads to better engine output and lower fuel consumption. Additionally, the precise management of the air-fuel ratio helps in reducing harmful emissions, making the engine more environmentally friendly 2.

Installation and Integration

Proper installation and integration of the Cummins 2870492 into a truck’s engine system involve several steps. It is important to follow manufacturer guidelines to ensure that the mixer is correctly positioned and connected. Prerequisites may include ensuring that the engine system is clean and free of debris, and that all connections are secure and properly sealed.

Troubleshooting Common Issues

Common problems associated with the Cummins 2870492 may include issues with air-fuel ratio imbalance, which can lead to poor engine performance or increased emissions. Troubleshooting steps may involve checking for leaks in the air intake system, ensuring that the mixer is properly aligned, and verifying that all connections are secure. Diagnostic tools can be used to monitor the air-fuel ratio and identify any discrepancies.

Maintenance Recommendations

To ensure the longevity and optimal performance of the Cummins 2870492, regular maintenance is recommended. This includes periodic checks for wear and tear, ensuring that all connections are tight, and cleaning the mixer to remove any buildup that may affect its performance. Servicing intervals should be followed as per the manufacturer’s guidelines to maintain efficiency.

Performance Monitoring

Monitoring the performance of the Cummins 2870492 can be achieved through the use of diagnostic tools and performance indicators. These tools help in assessing the air-fuel ratio and identifying any deviations that may indicate a need for adjustment or maintenance. Regular performance checks ensure that the mixer continues to operate within optimal parameters.

Cummins Corporation Overview

Cummins Corporation is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins offers a wide range of products designed to meet the needs of various industries, including automotive, construction, and agriculture. The company’s dedication to advancing technology and improving efficiency is evident in its product lineup, which includes the Cummins 2870492 Air Fuel Mixer 3.

Role of Part 2870492 Air Fuel Mixer in Engine Systems

The Air Fuel Mixer, identified by part number 2870492, is an integral component in the efficient operation of engine systems. Its primary function is to blend air and fuel in precise ratios, which is essential for optimal combustion. This process is facilitated through its interaction with several key components:

Interaction with the Module

The module, often a part of the engine’s electronic control unit (ECU), relies on the Air Fuel Mixer to deliver a consistent air-fuel mixture. The module monitors various parameters such as engine load, temperature, and throttle position. It then sends signals to the Air Fuel Mixer to adjust the mixture accordingly. This ensures that the engine operates within its optimal performance range, enhancing both power output and fuel efficiency.

Coordination with Fuel Control

The Fuel Control system works in tandem with the Air Fuel Mixer to regulate the amount of fuel injected into the engine. The Air Fuel Mixer ensures that the fuel is properly atomized and mixed with the incoming air. This atomized mixture is then delivered to the combustion chamber, where it is ignited. The Fuel Control system adjusts the fuel delivery based on the mixture ratio provided by the Air Fuel Mixer, ensuring that the engine maintains its desired performance characteristics under varying conditions.

Overall Engine Performance

By precisely controlling the air-fuel mixture, part 2870492 contributes to several aspects of engine performance:

- Efficiency: A well-mixed air-fuel ratio leads to more complete combustion, which translates to better fuel efficiency.

- Power: Optimal air-fuel mixtures allow the engine to produce maximum power output.

- Emissions: Proper mixture control helps in reducing harmful emissions, making the engine more environmentally friendly.

- Durability: Consistent and correct air-fuel ratios prevent engine knocking and other forms of mechanical stress, thereby extending the engine’s lifespan.

Conclusion

In summary, the Air Fuel Mixer (part 2870492) plays a significant role in ensuring that the engine operates smoothly and efficiently by working in concert with the module and Fuel Control system. Its precise management of the air-fuel ratio contributes to improved engine performance, enhanced fuel efficiency, and reduced emissions, making it a vital component in the operation of heavy-duty engines.

-

Reif, Konrad. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.