This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

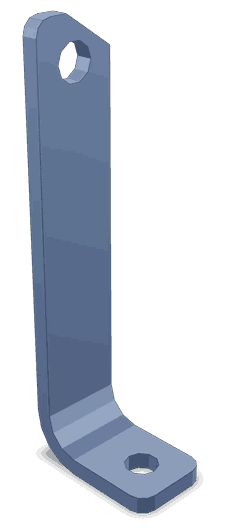

The Water Drain Tube 3000953, manufactured by Cummins, is a component designed to facilitate the drainage of water from various parts of commercial trucks. This part is integral to maintaining the operational efficiency and safety of the vehicle. Cummins, a well-established name in the industry, is known for its commitment to quality and innovation in manufacturing truck components 1.

Basic Concepts of Water Drain Tubes

A Water Drain Tube is a component that allows for the removal of accumulated water from specific areas within a truck’s system. Its function is to prevent water buildup, which can lead to corrosion, reduced efficiency, and potential safety hazards. By enabling the drainage of water, these tubes help maintain the truck’s overall performance and longevity 2.

Purpose of the 3000953 Water Drain Tube

The 3000953 Water Drain Tube plays a role in the truck’s system by facilitating the drainage of water from particular components or systems. This drainage is vital for preventing water accumulation, which can otherwise lead to corrosion and decreased efficiency of the truck’s components. By ensuring that water is efficiently drained, the tube contributes to the smooth operation and safety of the vehicle 3.

Key Features

The 3000953 Water Drain Tube is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features that enhance its performance and longevity, such as a robust construction that resists corrosion and wear. Additionally, the tube is engineered to fit precisely within the truck’s system, ensuring effective water drainage 4.

Benefits of Using the 3000953 Water Drain Tube

Utilizing the 3000953 Water Drain Tube offers several advantages. It contributes to improved system performance by ensuring that water does not accumulate in critical areas. The tube’s durable construction and precise fit also enhance the longevity of the truck’s components by preventing corrosion. Furthermore, its design allows for easier maintenance, reducing the time and effort required for upkeep 5.

Installation Process

Installing the 3000953 Water Drain Tube involves several steps to ensure proper fitting and function. First, the area where the tube will be installed should be cleaned and inspected for any debris or damage. The tube is then positioned according to the manufacturer’s instructions, ensuring it aligns correctly with the drainage system. Tools required may include wrenches for tightening connections and a cleaning brush for preparing the installation area. It is important to follow the installation guidelines closely to ensure the tube functions as intended 6.

Troubleshooting Common Issues

Common problems associated with Water Drain Tubes can include blockages or leaks. Blockages may occur due to debris accumulation within the tube, while leaks can result from improper installation or wear and tear. To address these issues, regular inspections are recommended to identify and resolve blockages promptly. For leaks, verifying the tube’s fit and condition can help determine if reinstallation or replacement is necessary 7.

Maintenance Tips

To ensure the optimal performance and longevity of the 3000953 Water Drain Tube, regular maintenance is advised. This includes inspecting the tube for signs of wear, corrosion, or blockages. Cleaning the tube and its surrounding areas can prevent debris accumulation, which may lead to blockages. Additionally, ensuring that all connections are secure and free from leaks will help maintain the efficiency of the drainage system 8.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the industry. Known for its commitment to quality and innovation, Cummins produces a wide range of components for commercial trucks. The company’s reputation is built on its dedication to enhancing the performance, safety, and reliability of its products. Cummins continues to lead in the development of advanced truck components, ensuring that its offerings meet the evolving needs of the industry 9.

Water Drain Tube Part 3000953 Compatibility with Cummins Engines

The Water Drain Tube part 3000953, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is crucial for maintaining the integrity and efficiency of the engine’s cooling system by facilitating the drainage of water and other contaminants.

N14 G and QSK19 CM2350 Engines

The Water Drain Tube part 3000953 is compatible with the N14 G and QSK19 CM2350 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction and transportation. The part ensures that water and other impurities are effectively removed from the engine’s cooling system, preventing potential damage and maintaining optimal engine performance.

K105 and V28 Engines

Similarly, the Water Drain Tube part 3000953 is also suitable for the K105 and V28 engines. These engines are typically used in a range of applications, including industrial and marine settings. The part’s design ensures that it fits precisely with these engines, providing a reliable solution for water drainage and contributing to the overall longevity and efficiency of the engine.

By ensuring that the Water Drain Tube part 3000953 is correctly installed, engine operators can maintain the health of their engines and avoid potential issues related to water accumulation and contamination.

Role of Part 3000953 Water Drain Tube in Engine Systems

The Part 3000953 Water Drain Tube is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the removal of accumulated water from critical areas, ensuring optimal performance and longevity of the engine.

Integration with Air Cleaner Systems

In air cleaner systems, the water drain tube is positioned to channel any moisture that may accumulate within the air cleaner housing. This is particularly important in dry type air cleaners and heavy-duty dry type cleaners, where the accumulation of water can impede airflow and reduce filtration efficiency. By effectively draining water, the tube helps maintain the integrity of the air filtration process, ensuring that the engine receives clean, dry air for combustion.

Interaction with Thermostat and Plumbing

The water drain tube also plays a supportive role in the engine’s cooling system. When integrated with the thermostat and plumbing components, it aids in the removal of condensate that may form within the cooling passages. This is vital for maintaining the thermostat’s operational efficiency, as water accumulation can lead to inconsistent temperature regulation. The tube ensures that the cooling system operates within specified parameters, contributing to engine stability and performance.

Contribution to Housing and Lever Mechanisms

In systems where the air cleaner housing incorporates lever mechanisms, such as the throttle lever, the water drain tube prevents water buildup that could otherwise lead to corrosion or mechanical failure. By ensuring that the housing remains dry, the tube supports the smooth operation of lever mechanisms, which are essential for precise engine control.

Overall System Benefits

The incorporation of the water drain tube into these systems underscores its importance in preventing water-related issues that can arise in various engine components. Its role in maintaining dry conditions within air cleaners, cooling systems, and mechanical housings is fundamental to the reliable and efficient operation of the engine.

Conclusion

The 3000953 Water Drain Tube is a critical component for maintaining the efficiency and safety of commercial trucks. Its role in preventing water accumulation, corrosion, and system inefficiencies cannot be overstated. Regular maintenance and proper installation are key to ensuring the longevity and performance of this Cummins part. By understanding the importance and functionality of the Water Drain Tube, truck operators and maintenance professionals can better ensure the reliability and performance of their vehicles.

-

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.