This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

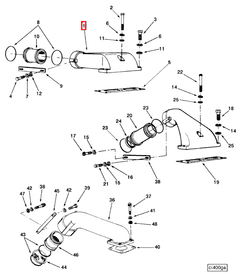

The Air Crossover Connection 3002087 by Cummins is a component designed to facilitate the operation of commercial trucks. Its purpose is to ensure the efficient distribution of compressed air within the truck’s air brake system. This part plays a role in maintaining consistent air pressure, which is vital for the reliable functioning of the braking system.

Basic Concepts of Air Crossover Connection

Air crossover connections are integral to the air brake systems found in commercial trucks. These components work by allowing the transfer of compressed air between different air lines within the system. This transfer ensures that air pressure is evenly distributed, which is necessary for the proper operation of the brakes. The air crossover connection acts as a junction point, enabling the system to respond quickly to changes in air pressure and ensuring that all brake components receive the necessary air to function correctly.

Purpose of the 3002087 Air Crossover Connection

This Cummins part is specifically designed to connect various air lines within a truck’s braking system. Its function is to provide a consistent and reliable pathway for compressed air to travel between different parts of the system. By ensuring that air pressure is evenly distributed, this component helps maintain the efficiency and safety of the truck’s braking system. It plays a role in connecting the primary and secondary air lines, allowing for a balanced distribution of air pressure across all brake components.

Key Features

The 3002087 is characterized by several key features that enhance its performance. It is constructed from durable materials that can withstand the high pressures and temperatures encountered in a truck’s air brake system. The connection types are designed to provide a secure and leak-free seal, ensuring that air pressure is maintained. Additionally, the design of the 3002087 includes features that facilitate easy installation and maintenance, such as accessible connection points and a robust construction that resists wear and corrosion.

Benefits

This part offers several advantages that contribute to the overall efficiency and reliability of a truck’s air brake system. By ensuring consistent air pressure distribution, it helps improve the system’s performance and reduces the likelihood of brake failures. The durable construction and secure connection types enhance the component’s reliability, making it a valuable part of the braking system. Additionally, the efficient design of the 3002087 can contribute to overall truck performance by ensuring that the braking system operates smoothly and effectively.

Installation Process

Installing the 3002087 requires careful attention to detail to ensure a secure and effective setup. The process involves several steps: first, the appropriate tools and replacement parts should be gathered. Next, the existing crossover connection, if present, should be removed, taking care to avoid damaging surrounding components. The new 3002087 connection should then be positioned and secured according to the manufacturer’s instructions, ensuring that all connections are tight and leak-free. Finally, the system should be tested to confirm that air pressure is distributed correctly and that there are no leaks.

Troubleshooting Common Issues

Common issues with the 3002087 may include leaks, inconsistent air pressure, or connection failures. To address these problems, a systematic approach to diagnosis is recommended. Begin by inspecting the connection points for signs of wear, corrosion, or damage. Check for leaks by listening for hissing sounds or feeling for escaping air. If a leak is detected, the connection may need to be tightened or replaced. Inconsistent air pressure may indicate a blockage or restriction within the air lines, which should be investigated and cleared. Regular maintenance and inspections can help prevent many of these issues.

Maintenance Tips

To keep the 3002087 in optimal condition, routine maintenance is recommended. This includes regular inspections for signs of wear, corrosion, or damage. Cleaning the connection points to remove dirt and debris can help prevent blockages and ensure a secure seal. Additionally, checking for leaks and ensuring that all connections are tight can help maintain consistent air pressure. If significant wear or damage is detected, the component may need to be replaced to ensure the continued reliability of the braking system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of high-quality products. Founded in 1919, Cummins has built a reputation for innovation, reliability, and performance. The company offers a diverse product line that includes engines, powertrains, and components designed for various applications, from on-highway trucks to off-highway equipment. Cummins’ commitment to quality and customer satisfaction is reflected in its products, including the 3002087, which is designed to meet the demanding requirements of commercial truck operations.

Cummins Air Crossover Connection Part 3002087

The Cummins Air Crossover Connection part 3002087 is a critical component in the air intake system of various Cummins engines. This part is designed to facilitate the smooth and efficient transfer of air between different sections of the engine’s intake manifold. Its primary function is to ensure that the air flow is evenly distributed, which is essential for maintaining optimal engine performance and efficiency 1.

In the K19 engine series, the Air Crossover Connection part 3002087 plays a pivotal role in the engine’s overall air management system. This part is engineered to connect different air intake paths, ensuring that the air is properly routed and balanced. This is particularly important in high-performance engines where precise air management can significantly impact power output and fuel efficiency 2.

The design of the Air Crossover Connection part 3002087 is such that it can be seamlessly integrated into the engine’s architecture. It is typically made from high-quality materials that can withstand the harsh conditions within the engine compartment, including high temperatures and pressures. This durability ensures that the part can maintain its functionality over the engine’s operational life.

In the broader context of Cummins engines, the Air Crossover Connection part 3002087 is a common component across various engine models. Its design and functionality are consistent, allowing for easy installation and compatibility with different engine configurations. This standardization makes it a versatile part that can be used in multiple engine applications, enhancing the overall efficiency and reliability of the engine systems.

For technicians and engineers working with Cummins engines, understanding the role of the Air Crossover Connection part 3002087 is crucial. Proper installation and maintenance of this part can significantly impact the engine’s performance, making it a key focus during engine diagnostics and repairs.

Role of Part 3002087 Air Crossover Connection in Engine Systems

The Air Crossover Connection (Part 3002087) is an essential component in the efficient operation of various engine systems, particularly those equipped with turbochargers and specific braking systems.

In turbocharged engines, the Air Crossover Connection facilitates the equal distribution of compressed air between the two sides of a V-type engine. This balanced air distribution ensures that both banks of the engine receive an equal amount of air, which is vital for maintaining consistent combustion and power output across all cylinders. The connection is typically integrated into the turbocharger kit, ensuring that the air flow is optimized from the turbocharger to the intake manifold.

When considering the arrangement of components within the engine bay, the Air Crossover Connection plays a significant role in the overall design. It allows for a more streamlined and efficient routing of air, reducing the potential for turbulence and ensuring that the air charge is as dense and cool as possible before it enters the combustion chambers. This contributes to improved engine performance and fuel efficiency.

In engines equipped with a Jacobs Brake, the Air Crossover Connection also supports the braking system’s functionality. The Jacobs Brake, or compression release engine brake, relies on the precise control of air and exhaust flow to generate braking force. The Air Crossover Connection ensures that the air flow is managed effectively, allowing the Jacobs Brake to operate smoothly and provide reliable deceleration without compromising engine performance.

Overall, the integration of the Air Crossover Connection (Part 3002087) into these engine systems enhances their efficiency, performance, and reliability, making it a key component in modern engine designs.

Conclusion

The 3002087 Air Crossover Connection by Cummins is a vital component in the air brake systems of commercial trucks and the air intake systems of various engines. Its role in ensuring consistent air pressure distribution and efficient air flow management contributes significantly to the performance, efficiency, and reliability of these systems. Proper installation, maintenance, and understanding of this part are essential for technicians and engineers to ensure optimal engine and braking system performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.