This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

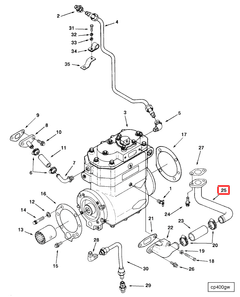

The Cummins 3012306 Air Compressor Inlet Connection is a component designed to facilitate the intake of air into the air compressor system of heavy-duty trucks. This part is integral to the efficient operation of the truck’s pneumatic system, ensuring that the compressor receives a steady and sufficient supply of air. Its role is significant in maintaining the overall performance and reliability of the vehicle’s air supply system 1.

Function and Operation

The Air Compressor Inlet Connection operates by allowing atmospheric air to enter the compressor. Once inside, the air is compressed and stored in reservoirs for various applications, such as powering brakes, suspensions, and other pneumatic systems within the truck. This component ensures that the air entering the system is clean and free from contaminants, which is vital for the compressor’s longevity and efficiency 2.

Purpose

The specific role of the 3012306 Air Compressor Inlet Connection in a truck’s operation is to provide a secure and efficient pathway for air to enter the compressor. It is designed to maintain the integrity of the air supply system by preventing leaks and ensuring that the air is properly filtered before compression. This function is crucial for the consistent performance of the truck’s pneumatic systems 3.

Key Features

The Cummins 3012306 Air Compressor Inlet Connection is constructed from durable materials that can withstand the high pressures and temperatures of the air compressor system. Its design includes features such as a robust connection point, filtration elements to clean the incoming air, and a secure sealing mechanism to prevent air leaks. These attributes contribute to the component’s performance and longevity.

Benefits

The benefits of the 3012306 Air Compressor Inlet Connection include improved efficiency in the air compressor system, enhanced durability under high-pressure conditions, and increased reliability in the truck’s pneumatic operations. These advantages contribute to the overall performance and safety of the vehicle.

Installation Process

Installing the 3012306 Air Compressor Inlet Connection involves several steps. First, the old connection, if present, must be removed. Then, the new connection is positioned and secured using the appropriate tools. It is important to ensure a tight seal to prevent air leaks and to follow manufacturer guidelines for torque specifications and alignment.

Common Issues and Troubleshooting

Common issues with the 3012306 Air Compressor Inlet Connection may include air leaks, contamination in the air supply, or connection failure. Troubleshooting these problems involves inspecting the connection for damage, ensuring the seal is intact, and cleaning or replacing the filter if necessary. Regular maintenance can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3012306 Air Compressor Inlet Connection, regular maintenance is recommended. This includes inspecting the connection for signs of wear or damage, cleaning the filter element, and checking the seal for integrity. Following these practices can help maintain the efficiency of the air compressor system.

Safety Considerations

When working with the 3012306 Air Compressor Inlet Connection, it is important to observe safety practices. This includes ensuring the truck’s engine is off and the air system is depressurized before beginning any work. Proper handling and installation of the component are crucial to prevent accidents and ensure safe operation of the vehicle.

Cummins Corporation Overview

Cummins Corporation is a well-established entity in the automotive and heavy-duty truck industry, known for its extensive range of products and commitment to quality. With a history of innovation and reliability, Cummins has built a reputation for producing components that enhance the performance and efficiency of vehicles across various applications.

Cummins Air Compressor Inlet Connection Part 3012306

The Cummins Air Compressor Inlet Connection part number 3012306 is a critical component designed to interface with various Cummins engines, ensuring efficient air supply to the air compressor system. This part is engineered to fit seamlessly with specific engine models, enhancing the overall performance and reliability of the air management system.

K19 Engines

For the K19 engines, the part 3012306 is meticulously crafted to align with the unique design and specifications of this engine series. Its precision fitment ensures that the air compressor receives the necessary airflow, contributing to the engine’s optimal operation.

QSK19 CM500 Engines

In the case of the QSK19 CM500 engines, the Cummins Air Compressor Inlet Connection part 3012306 is tailored to integrate with the advanced features and robust construction of these engines. This part’s design facilitates a secure and efficient connection, supporting the air compressor’s role in maintaining engine performance.

Grouping of Engines

The part 3012306 is specifically engineered to fit with the K19 and QSK19 CM500 engines, ensuring compatibility and performance across these models. Its design reflects Cummins’ commitment to providing high-quality components that meet the stringent demands of these engines.

Role of Part 3012306 Air Compressor Inlet Connection in Engine Systems

The Part 3012306 Air Compressor Inlet Connection is an essential component in the efficient operation of various engine systems. It serves as the primary interface between the air compressor and the air supply tube, ensuring a secure and leak-free connection. This part is integral to the overall performance and reliability of the engine system.

Integration with Key Components

-

Air Compressor: The inlet connection is directly attached to the air compressor, allowing it to draw in ambient air efficiently. This connection ensures that the compressor receives a consistent and uninterrupted air supply, which is vital for its operation.

-

Air Supply Tube: The connection acts as a bridge between the compressor and the air supply tube. It facilitates the smooth transfer of compressed air from the compressor to other parts of the engine system, such as the compressor air inlet.

-

Compressor Air Inlet: This component relies on the inlet connection to receive pressurized air. The secure fitting provided by Part 3012306 ensures that the air inlet operates under optimal conditions, contributing to the overall efficiency of the compressor.

-

Compressor: The overall functionality of the compressor is enhanced by the reliable connection provided by Part 3012306. It ensures that the compressor can maintain consistent pressure levels, which is essential for its performance.

-

Air Connection: The inlet connection is a critical part of the broader air connection system within the engine. It helps maintain the integrity of the air pathway, preventing leaks and ensuring that the air supply remains consistent.

-

Air Compressor Inlet: This specific component benefits from the secure and efficient connection provided by Part 3012306. It ensures that the inlet can effectively manage the flow of air into the compressor, enhancing its operational efficiency.

Conclusion

In summary, the 3012306 Air Compressor Inlet Connection plays a significant role in maintaining the efficiency and reliability of the engine system by ensuring secure and leak-free connections between critical components. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.