This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

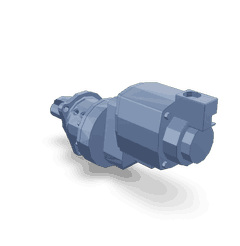

The Air Starting Motor 3022692, manufactured by Cummins, is a specialized component designed for the operation of heavy-duty trucks. Cummins, a well-established name in the automotive industry, is renowned for its robust and reliable engine solutions. The 3022692 Air Starting Motor is integral to the efficient start-up of diesel engines in heavy-duty trucks, ensuring that these vehicles can operate under a variety of conditions 1.

Basic Concepts of Air Starting Motors

Air starting motors operate on the principle of converting pneumatic energy into mechanical motion. This is achieved by using compressed air, which is a common and readily available source of power in heavy-duty truck applications. When activated, the compressed air enters the motor, causing a piston to move. This motion is then transferred to the engine’s flywheel, initiating the start-up process. The efficiency and reliability of this system make it a preferred choice for starting diesel engines in demanding environments 2.

Purpose of the 3022692 Air Starting Motor

The 3022692 Air Starting Motor serves a vital function in the operation of heavy-duty trucks. Its primary role is to facilitate the start-up of the diesel engine under various conditions, including cold starts and in situations where the battery may be insufficient. By providing a reliable and consistent means of engine initiation, the 3022692 ensures that the truck can be operational with minimal delay, which is crucial in logistics and transportation sectors 3.

Key Features

The 3022692 Air Starting Motor is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring longevity in harsh operating environments. The motor also features advanced technological elements that improve its efficiency and reliability. These include precision-engineered components and robust construction, which contribute to its overall effectiveness in demanding applications 4.

Benefits

The advantages of the 3022692 Air Starting Motor are manifold. It offers improved reliability, ensuring consistent engine start-ups even in challenging conditions. Its efficient design contributes to better overall performance of the truck, reducing downtime and increasing operational efficiency. Additionally, the motor’s durability and resistance to wear mean that it requires less frequent maintenance, further enhancing its value in heavy-duty truck applications 5.

Installation Process

Installing the 3022692 Air Starting Motor requires careful attention to detail. The process begins with ensuring that the engine is in a safe and stable condition. The motor should be aligned correctly with the engine’s flywheel, and all connections, including pneumatic and electrical, must be secure. It is important to follow the manufacturer’s guidelines to ensure proper installation and to avoid any potential issues during operation 6.

Operational Guidelines

Operating the 3022692 Air Starting Motor involves adhering to specific guidelines to ensure safe and efficient engine start-ups. It is important to manage air pressure correctly, as excessive pressure can damage the motor. The recommended practice is to follow a gradual increase in pressure to start the engine smoothly. Regular checks of the motor and its connections are also advised to maintain optimal performance 7.

Troubleshooting Common Issues

Common issues with the 3022692 Air Starting Motor may include failure to start, unusual noises, or leaks. These problems can often be traced to incorrect installation, worn components, or issues with the air supply. Troubleshooting involves checking the motor’s alignment, inspecting for wear or damage, and ensuring that the air supply is clean and at the correct pressure. Addressing these issues promptly can prevent more serious problems and ensure the motor’s longevity 8.

Maintenance Tips

Regular maintenance is key to the longevity and optimal performance of the 3022692 Air Starting Motor. This includes routine lubrication of moving parts, inspection for wear or damage, and cleaning to remove any debris or contaminants. Adhering to a scheduled maintenance plan can significantly extend the life of the motor and ensure consistent performance 9.

Safety Considerations

When working with the 3022692 Air Starting Motor, it is important to observe several safety guidelines. This includes ensuring that the motor is turned off and depressurized before any maintenance or inspection is performed. Personal protective equipment should be worn, and all work should be conducted in a well-ventilated area. Adhering to these safety practices helps prevent accidents and ensures a safe working environment 10.

Cummins Corporation

Cummins Corporation, the manufacturer of the 3022692 Air Starting Motor, has a long-standing reputation in the automotive industry. Founded in 1919, Cummins has grown to become a global leader in diesel engine manufacturing, with a diverse product range that includes engines, filtration systems, and power generation equipment. The company is known for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry 11.

Compatibility of Cummins Air Starting Motor 3022692

The Cummins Air Starting Motor part number 3022692 is a critical component in the starting systems of various diesel engines. This part is designed to provide the necessary power to initiate the engine’s combustion process using compressed air.

N14 MECHANICAL

The N14 MECHANICAL engine is a robust and reliable power unit often used in heavy-duty applications. The Cummins Air Starting Motor 3022692 is engineered to seamlessly integrate with the N14 MECHANICAL engine’s starting system. This motor ensures efficient and reliable engine starts, even in challenging conditions.

NH/NT 855

The NH/NT 855 engines are part of Cummins’ lineup of high-performance diesel engines, known for their durability and power. The Air Starting Motor 3022692 is specifically tailored to fit these engines, ensuring that the starting process is both quick and reliable.

Grouping of Engines

Both the N14 MECHANICAL and NH/NT 855 engines benefit from the use of the Cummins Air Starting Motor 3022692. This part is designed to fit within the broader framework of Cummins’ engine technology, ensuring that it works effectively across different engine models.

Role of Part 3022692 Air Starting Motor in Engine Systems

The part 3022692 Air Starting Motor is integral to the functionality of various engine systems, particularly in marine and industrial applications where air start systems are prevalent. This component is designed to convert pneumatic energy into mechanical energy, facilitating the initial rotation of the engine.

Integration with Air Starter Mounting

When integrated with an air starter mounting, the 3022692 Air Starting Motor ensures a secure and stable connection to the engine. The mounting system is engineered to withstand the substantial forces generated during the starting process, providing a reliable interface between the motor and the engine.

Interaction with the Motor

The 3022692 Air Starting Motor works in conjunction with the main engine motor to initiate the starting sequence. Upon activation, the air starting motor engages with the engine’s flywheel, using compressed air to generate the necessary torque.

Contribution to the Starting System

In the starting system, the 3022692 Air Starting Motor plays a significant role by providing the initial momentum required to overcome the engine’s inertia. This is particularly important in large diesel engines where electric starters may not be sufficient.

Conclusion

Overall, the 3022692 Air Starting Motor is a key component that enhances the reliability and efficiency of engine starting systems, ensuring that engines can be brought to operational speed quickly and dependably.

-

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F2.5 CM2620 F150B, Bulletin Number 5677025.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.