This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

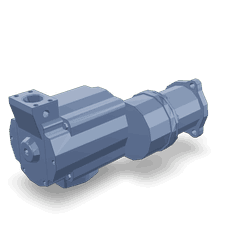

The Cummins 3026797 Air Starting Motor is a specialized component designed for the reliable and efficient starting of diesel engines in commercial trucks. Its role is significant in ensuring that the engine can be started under various conditions, contributing to the overall operational efficiency and reliability of the vehicle 2.

Basic Concepts of Air Starting Motors

Air starting motors operate on the principle of converting pneumatic energy into mechanical motion. This is achieved by using compressed air, which is a common feature in many commercial trucks, to drive the motor. The compressed air enters the motor and expands, pushing against pistons or turbines within the motor. This expansion generates the mechanical force needed to turn the engine’s crankshaft, initiating the start-up process of the diesel engine 3.

Operation of the Cummins 3026797 Air Starting Motor

Within the context of a commercial truck’s engine starting system, the Cummins 3026797 Air Starting Motor functions by receiving compressed air from the truck’s air system. This air is directed into the motor, where it expands and drives the internal components. The motor is connected to the engine’s flywheel or crankshaft, allowing it to turn the engine over. Once the engine starts, the air starting motor disengages, and the engine operates independently 4.

Key Features

The Cummins 3026797 Air Starting Motor is characterized by several key features. Its design incorporates robust materials to withstand the harsh conditions typical in commercial trucking environments. The motor is constructed with high-quality metals and precision-machined components to ensure durability and reliable performance. Additionally, it may include technological aspects such as advanced sealing mechanisms to prevent air leaks and ensure efficient operation 1.

Benefits of Using the Cummins 3026797 Air Starting Motor

The Cummins 3026797 Air Starting Motor offers several advantages for commercial trucks. Its reliable operation ensures that the engine can be started consistently, even in challenging conditions. The efficiency of the motor contributes to reduced starting times and lower fuel consumption during the start-up phase. Furthermore, the motor’s performance enhancements can lead to improved overall engine reliability and longevity 2.

Installation Process

Installing the Cummins 3026797 Air Starting Motor requires careful attention to detail and adherence to safety protocols. The process involves preparing the engine by ensuring it is clean and free of any obstructions. The motor should be aligned correctly with the engine’s flywheel or crankshaft before securing it in place. It is important to follow the manufacturer’s instructions regarding torque specifications for tightening bolts and ensuring all connections are secure. Safety precautions, such as wearing protective gear and ensuring the area is well-ventilated, should be observed throughout the installation process 3.

Maintenance and Troubleshooting

To ensure optimal performance of the Cummins 3026797 Air Starting Motor, regular maintenance is recommended. This includes checking for any signs of wear or damage, ensuring all connections are tight, and verifying that the motor is free of debris. Common troubleshooting tips involve inspecting the air supply lines for leaks, ensuring the motor is receiving adequate compressed air, and checking the motor’s electrical connections if applicable. Addressing these areas can help prevent issues and maintain the motor’s efficiency 4.

Safety Considerations

When working with the Cummins 3026797 Air Starting Motor, it is important to observe several safety protocols. These include ensuring that the engine is turned off and the key is removed before beginning any work. Wearing appropriate protective gear, such as gloves and safety glasses, is crucial. Additionally, working in a well-ventilated area and being aware of the high-pressure air involved in the motor’s operation can help prevent accidents and injuries 1.

Compatibility

The Cummins Air Starting Motor part number 3026797 is designed to be compatible with a range of engines, ensuring reliable and efficient starting capabilities across various applications. Here is a detailed look at the engines with which this air starting motor is compatible:

K-Series Engines

- K19

- K38

- K50

These K-Series engines benefit from the robust design of the 3026797 air starting motor, providing dependable starting power in demanding conditions.

QSK-Series Engines

- QSK19 CM2350

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

The QSK-Series engines, known for their high performance and durability, are well-suited for the 3026797 air starting motor. This compatibility ensures that these engines can start reliably, even in challenging environments.

QST-Series Engines

- QST30 CM2350 T101

- QST30 CM552

The QST-Series engines, with their advanced technology and performance, are also compatible with the 3026797 air starting motor. This compatibility is crucial for maintaining the high standards of performance expected from these engines.

Other Compatible Engines

- V28

The V28 engine, known for its versatility and efficiency, is another engine that can utilize the 3026797 air starting motor. This compatibility ensures that the V28 engine can start reliably and efficiently, meeting the needs of various applications.

By ensuring compatibility with these engines, the Cummins Air Starting Motor 3026797 provides a reliable solution for starting needs across a wide range of applications 2.

Integration in Engine Systems

The 3026797 Air Starting Motor is a specialized component designed to enhance the functionality of various engine systems through its integration with several key components. This motor is engineered to work seamlessly with an Air Starter, ensuring efficient engine start-ups by utilizing compressed air.

When paired with a Kit that includes On-Board Spares, the Air Starting Motor provides a reliable solution for maintaining engine operations even in the event of component failure. This setup ensures that essential spare parts are readily available, minimizing downtime and enhancing overall system reliability.

The motor is also compatible with Starting Motors, creating a robust starting system that can handle the demands of high-performance engines. This integration allows for a more responsive and efficient starting process, reducing the strain on the engine during start-up.

In conjunction with Plumbing components, the Air Starting Motor ensures that air is efficiently distributed throughout the system, maintaining optimal pressure levels required for consistent performance. This is particularly important in systems where precise air management is necessary for engine reliability.

When used with a Prelub Air Starter RB, the motor contributes to a smoother start-up process by ensuring that critical engine components are lubricated before the engine begins to run. This pre-lubrication is essential for reducing wear and tear on engine parts, prolonging their lifespan.

Additionally, the motor is designed to work with a Spare Parts Kit, which includes essential components needed for quick repairs and maintenance. This kit ensures that any issues can be addressed promptly, keeping the engine system operational with minimal interruption.

Overall, the 3026797 Air Starting Motor plays a significant role in enhancing the performance and reliability of engine systems by integrating with various components to ensure efficient and dependable operation 3.

Conclusion

The Cummins 3026797 Air Starting Motor is a critical component for the reliable and efficient starting of diesel engines in commercial trucks. Its robust design, compatibility with various engines, and integration with key engine components ensure that it plays a significant role in enhancing engine performance and reliability. Regular maintenance, adherence to safety protocols, and understanding its operation and benefits are essential for maximizing the efficiency and longevity of this Cummins part 4.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ ↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ ↩ ↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ ↩ ↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.