This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3028847 Air Cleaner is a component designed for use in commercial trucks. Its purpose is to filter the air that enters the engine, ensuring that only clean air reaches the combustion chambers. This part plays a significant role in maintaining engine efficiency and longevity by preventing contaminants from entering the engine 1.

Basic Concepts of Air Cleaners

Air cleaners operate on the principle of filtration. As air enters the engine, it passes through a filter medium that traps particles such as dust, dirt, and other contaminants. This process ensures that the air entering the combustion chambers is clean, which is vital for optimal engine performance and durability. The effectiveness of an air cleaner is measured by its ability to capture particles of various sizes while allowing sufficient airflow to meet the engine’s requirements 2.

Purpose of the Cummins 3028847 Air Cleaner

The Cummins 3028847 Air Cleaner is specifically designed to filter air entering the engine of commercial trucks. By capturing contaminants, it helps protect the engine’s internal components from wear and damage. This part contributes to maintaining engine efficiency, ensuring that the combustion process occurs under optimal conditions, which in turn supports the overall performance and reliability of the truck 3.

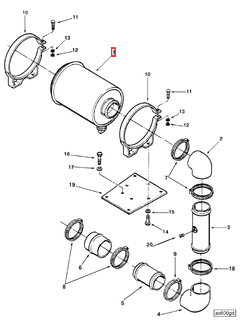

Key Features

The Cummins 3028847 Air Cleaner is characterized by its robust design and the quality of materials used in its construction. It features a high-efficiency filter element that captures a wide range of particle sizes. The air cleaner is also designed for easy installation and maintenance, with a secure mounting system that ensures it remains in place under various driving conditions. Additionally, its construction allows for maximum airflow, balancing the need for filtration with the engine’s air requirements 4.

Benefits

The use of the Cummins 3028847 Air Cleaner offers several advantages. It contributes to improved engine performance by ensuring that the air entering the engine is clean. This leads to more efficient combustion, which can enhance fuel efficiency and reduce emissions. Furthermore, by protecting the engine from contaminants, the air cleaner helps extend the engine’s lifespan, reducing the need for frequent maintenance and repairs 5.

Installation Process

Installing the Cummins 3028847 Air Cleaner involves several steps. First, the old air cleaner, if present, should be removed. This may require disconnecting hoses or removing mounting brackets. Once the area is clear, the new air cleaner can be positioned and secured in place using the provided mounting hardware. It is important to ensure that all connections are secure and that the air cleaner is properly aligned to allow for optimal airflow. Tools required may include wrenches and screwdrivers, depending on the specific truck model 6.

Maintenance Tips

To ensure the Cummins 3028847 Air Cleaner operates effectively, regular maintenance is recommended. This includes inspecting the air cleaner element for signs of clogging or damage and cleaning or replacing it as necessary. The frequency of maintenance will depend on the operating conditions and the manufacturer’s recommendations. Keeping the air cleaner in good condition will help maintain engine performance and efficiency 7.

Troubleshooting Common Issues

Common issues with the Cummins 3028847 Air Cleaner may include reduced airflow due to a clogged filter element or leaks in the air intake system. If airflow is restricted, inspecting and possibly replacing the filter element can resolve the issue. For leaks, checking the connections and seals around the air cleaner can identify and fix the problem. Regular maintenance and inspections can help prevent these issues from occurring 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses. Cummins’ commitment to excellence is reflected in its products, which are known for their reliability, performance, and durability 9.

Compatibility

The Cummins Air Cleaner part number 3028847 is designed to fit a variety of engine models, ensuring optimal air filtration and engine performance. This air cleaner is compatible with the following engines:

K19 Series

- K19

K38 Series

- K38

K50 Series

- K50

QSK19 CM500 Series

- QSK19 CM500

This air cleaner is engineered to provide efficient air filtration, which is crucial for maintaining engine efficiency and longevity. It is essential to ensure that the air cleaner is properly installed and maintained to achieve the best performance from these engines 10.

Role in Engine Systems

The Cummins 3028847 Air Cleaner is an integral component in the engine system, working in conjunction with several other parts to ensure optimal engine performance and longevity.

Integration with the Intake System

The air cleaner is designed to fit seamlessly into the intake system of an engine. Its primary function is to filter incoming air before it reaches the carburetor or fuel injection system. This ensures that the air entering the engine is free from contaminants such as dust, dirt, and other particulates that could cause wear and tear on internal components 11.

Relationship with the Carburetor

In engines equipped with a carburetor, the air cleaner is positioned upstream. It supplies clean air to the carburetor, where it mixes with fuel to create a combustible mixture. The efficiency of this mixture is significantly influenced by the quality of the air supplied by the air cleaner. A well-maintained air cleaner ensures that the carburetor operates within its designed parameters, promoting efficient fuel combustion and reducing emissions 12.

Compatibility with Fuel Injection Systems

For engines with fuel injection systems, the air cleaner ensures that the air mass flowing into the intake manifold is clean, which is essential for the accurate operation of the mass airflow sensor (MAF) or manifold absolute pressure (MAP) sensor. These sensors rely on clean air data to deliver the correct fuel-to-air ratio, optimizing engine performance and fuel efficiency 13.

Interaction with the Engine Control Unit (ECU)

Modern engines are equipped with an Engine Control Unit (ECU) that monitors and adjusts various parameters for optimal performance. The air cleaner indirectly influences the ECU’s operations by ensuring that the air quality remains consistent. This stability allows the ECU to make precise adjustments to fuel delivery and ignition timing, enhancing overall engine efficiency and reducing the likelihood of misfires or other performance issues 14.

Contribution to Engine Longevity

By filtering out contaminants, the air cleaner protects various engine components, including the cylinders, pistons, and valves, from abrasive wear. This protection is vital for maintaining engine efficiency over time and extends the overall lifespan of the engine 15.

Conclusion

The Cummins 3028847 Air Cleaner is a fundamental component that works in harmony with the intake system, carburetor or fuel injection system, and the ECU to ensure the engine operates efficiently and remains protected from harmful particulates. Regular maintenance and proper installation are crucial to achieving optimal performance and longevity from this Cummins part.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Cummins Inc. ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Bulletin Number 4021570, Troubleshooting and Repair Manual.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Cummins Inc. ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Bulletin Number 4021570, Troubleshooting and Repair Manual.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Cummins Inc. ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Bulletin Number 4021570, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Bulletin Number 4021570, Troubleshooting and Repair Manual.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Cummins Inc. ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Bulletin Number 4021570, Troubleshooting and Repair Manual.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Cummins Inc. ISB, ISC, ISL, ISBe, ISDe, and QSB3.3 CM2150 Electronic Control System. Bulletin Number 4021570, Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.