This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Air Fuel Throttle Valve (3080383) by Cummins is a component designed to regulate the air and fuel mixture entering the engine of commercial trucks. Its purpose is to ensure optimal combustion efficiency, which directly influences engine performance and fuel economy. The significance of this valve lies in its ability to maintain precise control over the air-fuel ratio, which is vital for the efficient operation of diesel engines 1.

Basic Concepts of Air Fuel Throttle Valves

Air fuel throttle valves operate on the principle of regulating the mixture of air and fuel that enters the combustion chamber of an engine. By controlling this mixture, the valve helps to optimize combustion efficiency, which is crucial for maximizing engine performance and fuel economy 2. The valve adjusts the flow of air and fuel in response to various engine operating conditions, ensuring that the engine receives the correct air-fuel ratio for efficient combustion.

Role of the 3080383 Air Fuel Throttle Valve in Truck Operation

The 3080383 Air Fuel Throttle Valve plays a significant role in the operation of commercial trucks by contributing to efficient engine performance. It regulates the air and fuel mixture to ensure optimal combustion, which directly impacts the engine’s power output and fuel efficiency. By maintaining the correct air-fuel ratio, the valve helps to reduce emissions and improve overall engine performance. Additionally, it aids in the smooth operation of the engine under varying load conditions, enhancing the driving experience and reliability of the truck.

Key Features of the 3080383 Air Fuel Throttle Valve

The 3080383 Air Fuel Throttle Valve is characterized by several notable features that contribute to its effectiveness and durability. These include precision engineering, which ensures accurate control of the air-fuel mixture, and robust construction, which enhances its longevity and reliability. The valve is also designed to be compatible with Cummins engines, ensuring seamless integration and optimal performance. Additionally, its design incorporates advanced materials and manufacturing techniques to withstand the harsh operating conditions typical of commercial truck environments.

Benefits of Using the 3080383 Air Fuel Throttle Valve

Utilizing the 3080383 Air Fuel Throttle Valve offers several advantages for commercial truck operators. These include improved engine performance due to optimized combustion efficiency, enhanced fuel efficiency leading to reduced operating costs, and reliable operation under a wide range of conditions. The valve’s precise control over the air-fuel mixture also contributes to lower emissions, aligning with environmental regulations and promoting sustainable operation. Furthermore, its durability and compatibility with Cummins engines ensure long-term reliability and minimal maintenance requirements.

Troubleshooting and Maintenance Tips

To ensure the optimal performance and longevity of the 3080383 Air Fuel Throttle Valve, it is important to be aware of common issues and follow recommended maintenance practices. Regular inspection for signs of wear or damage, such as leaks or unusual noises, can help identify potential problems early. Cleaning the valve and its surrounding components to remove any buildup of dirt or debris is also crucial for maintaining efficient operation. Additionally, following the manufacturer’s guidelines for periodic maintenance and replacement can help prevent unexpected failures and ensure the valve continues to operate effectively.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the field of diesel engine technology. The company’s commitment to advancing engine performance, efficiency, and sustainability is evident in its wide range of products and solutions designed for various applications, including commercial trucks, construction equipment, and power generation. Cummins continues to invest in research and development to push the boundaries of engine technology and provide customers with cutting-edge solutions for their power needs.

Role of Part 3080383 Air Fuel Throttle Valve in Engine Systems

The Part 3080383 Air Fuel Throttle Valve is an essential component that interacts with various engine systems to optimize performance and efficiency.

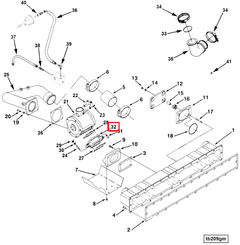

Interaction with Turbocharger Arrangement

In engines equipped with a turbocharger arrangement, the Air Fuel Throttle Valve works in concert with the turbocharger to manage airflow. The valve modulates the air entering the intake manifold, ensuring that the turbocharged system receives the optimal air-fuel mixture. This coordination enhances the turbocharger’s efficiency, allowing it to deliver improved power output and better throttle response 3.

Coordination with Turbocharger

When integrated with a turbocharger, the Air Fuel Throttle Valve plays a significant role in maintaining the desired boost levels. By precisely controlling the airflow, the valve helps prevent over-boosting or under-boosting scenarios. This ensures that the turbocharger operates within its optimal range, contributing to both performance and longevity of the turbo system.

Function in Carburetor Systems

In engines utilizing a carburetor, the Air Fuel Throttle Valve assists in fine-tuning the air-fuel ratio. Unlike fuel injection systems, carburetors rely on mechanical means to mix air and fuel. The valve helps achieve a more consistent and efficient mixture, improving overall engine performance and fuel economy. It also aids in reducing emissions by ensuring a cleaner burn.

General Arrangement Integration

In a general engine arrangement, the Air Fuel Throttle Valve is positioned to interact with the intake system components. It works alongside sensors and control units to dynamically adjust the air-fuel ratio based on driving conditions. This integration allows for real-time adjustments, enhancing drivability and ensuring that the engine operates efficiently across a wide range of conditions.

Conclusion

The 3080383 Air Fuel Throttle Valve is a critical component for Cummins engines, including the L10 GAS engine. Its precise control over airflow ensures optimal engine performance, fuel efficiency, and emissions control, making it an essential part for maintaining the engine’s health and longevity. Regular maintenance and adherence to manufacturer guidelines are crucial for ensuring the valve’s optimal performance and longevity.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Cummins Engine Technology Overview. Retrieved from Cummins official website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.