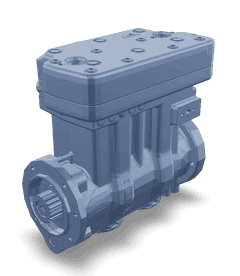

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3103412 Air Compressor is a component designed for use in commercial trucks. It serves to provide compressed air, which is necessary for various systems within the vehicle, including the braking system, suspension, and other pneumatic controls. The compressor’s role is significant as it ensures that these systems operate efficiently and reliably, contributing to the overall performance and safety of the truck 1.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. It works by drawing in air, compressing it, and then storing it in a tank until needed. In commercial trucks, air compressors are vital for powering systems that require a consistent supply of compressed air. These systems include the air brake system, which relies on compressed air to function, and various pneumatic controls that enhance the truck’s operational capabilities 2.

Purpose of the Cummins 3103412 Air Compressor

This part is integral to the operation of a truck. It provides the compressed air necessary for the air brake system, which is crucial for safe and effective braking. Additionally, it supports other pneumatic systems, such as the suspension and any auxiliary equipment that requires compressed air to operate. By maintaining a steady supply of compressed air, the compressor ensures that these systems function correctly and contribute to the truck’s overall performance 3.

Key Features

This Cummins part boasts several key features that enhance its functionality and durability. Its design incorporates high-quality materials that resist wear and corrosion, ensuring longevity. Technological advancements within the compressor improve its efficiency, allowing it to operate with reduced energy consumption. These features contribute to the compressor’s reliability and performance in demanding commercial truck environments 4.

Benefits

Utilizing the 3103412 offers several benefits. Its efficient design leads to improved fuel economy, as less power is required to operate the compressor. The compressor’s reliability reduces downtime, ensuring that trucks remain operational. Additionally, its performance enhances the functionality of pneumatic systems, contributing to safer and more efficient truck operations 5.

Installation Process

Installing this part involves several steps. First, ensure the truck’s engine is off and cooled down. Then, locate the compressor mounting area and connect the necessary hoses and electrical connections. Secure the compressor in place using the provided mounting brackets. Finally, test the system to ensure proper operation. Tools required may include wrenches, electrical testers, and hose clamps. Always follow safety precautions during installation 6.

Common Applications

The 3103412 is commonly used in various types of commercial trucks, including semi-trucks, dump trucks, and vocational vehicles. It is suitable for fleet operations that require reliable and efficient compressed air systems. Its applications extend to any commercial truck that utilizes pneumatic systems for braking, suspension, or auxiliary equipment 7.

Troubleshooting

When encountering issues with this part, it is important to identify the symptoms and potential causes. Common problems may include insufficient air pressure, unusual noises, or compressor failure. Solutions can range from checking and tightening connections to replacing worn-out components. Regular inspections and maintenance can help prevent many issues 8.

Maintenance Tips

To ensure the longevity and optimal performance of the 3103412, regular maintenance is recommended. This includes checking for leaks in the system, ensuring all connections are secure, and monitoring the compressor’s performance. Additionally, keeping the compressor clean and free of debris will contribute to its efficient operation 9.

Safety Considerations

When working with this part, it is important to observe safety considerations. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, when handling the compressor. Ensure the truck’s engine is off before performing any maintenance or repairs. In case of an emergency, follow the manufacturer’s guidelines for safe operation and shutdown procedures 10.

Environmental Impact

The use of the 3103412 has an environmental impact, primarily through its energy consumption and the potential for refrigerant leaks if applicable. However, Cummins Inc. incorporates eco-friendly features in its designs, such as energy-efficient compressors and the use of environmentally safe materials, to minimize this impact 11.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its commitment to excellence and customer satisfaction has made it a preferred choice for commercial truck operators worldwide 12.

Compatibility with Cummins Engines

The 3103412 is specifically designed to integrate with the QSK60 CM500 and QST30 CM552 engines. These engines are known for their robust construction and high performance, making them suitable for demanding industrial and marine applications. The air compressor plays a role in these engines by providing the necessary compressed air for various functions, including starting the engine, powering air tools, and maintaining the air brake system 13.

Installation and Functionality

When installed in the QSK60 CM500 and QST30 CM552 engines, the 3103412 ensures that the engine receives a steady supply of compressed air. This is vital for the efficient operation of the engine’s systems, particularly during startup and under heavy load conditions. The compressor’s design allows for easy installation and maintenance, ensuring that the engine can operate at peak efficiency with minimal downtime 14.

Performance and Reliability

The 3103412 is built to withstand the rigors of continuous operation in demanding environments. Its robust construction and high-quality materials ensure long-lasting performance and reliability. This makes it an ideal choice for operators who require dependable air supply systems for their Cummins engines 15.

Maintenance and Support

Regular maintenance of the 3103412 is essential to ensure its longevity and performance. Cummins provides comprehensive support and service for this part, including detailed maintenance guidelines and access to genuine replacement parts. This ensures that operators can maintain their engines’ air supply systems with confidence, knowing that they have access to the necessary resources and support 16.

Role of Part 3103412 in Engine Systems

The air compressor, identified by part number 3103412, is integral to the operation of various engine systems. It is primarily responsible for generating compressed air, which is essential for several functions within the engine.

Fuel Injection System

In modern fuel injection systems, the air compressor provides the necessary pressurized air to atomize the fuel. This ensures a fine mist of fuel is delivered into the combustion chamber, enhancing fuel efficiency and reducing emissions. The compressed air also aids in the precise delivery of fuel, contributing to optimal engine performance 17.

Brake System

For vehicles equipped with air brakes, the air compressor is vital. It builds and maintains the air pressure required to operate the brake system. This ensures that the brakes respond promptly and effectively, enhancing vehicle safety 18.

Suspension System

Some advanced suspension systems utilize air springs, which rely on compressed air to adjust the ride height and damping characteristics. The air compressor supplies the air needed to inflate and deflate these air springs, allowing for dynamic adjustments based on driving conditions 19.

Pneumatic Tools

In maintenance and repair scenarios, the compressed air from the air compressor powers various pneumatic tools. These tools, such as drills, grinders, and impact wrenches, require a steady supply of pressurized air to function efficiently 20.

Cabin Comfort Systems

In certain vehicle designs, the air compressor contributes to cabin comfort by powering features like air suspension seats and climate control systems. It ensures that these systems operate smoothly, enhancing the overall driving experience 21.

Emission Control Systems

The air compressor also plays a role in emission control systems by providing the necessary air pressure for components like the evaporative emission control system. This helps in capturing and storing fuel vapors, preventing them from escaping into the atmosphere 22.

Starting Systems

In some diesel engines, the air compressor is used in the starting system. It provides the compressed air needed to initiate the engine’s start-up process, ensuring reliable ignition even in cold conditions 23.

Conclusion

By understanding the multifaceted role of the air compressor in these engine systems, engineers and mechanics can better appreciate its importance and ensure its proper maintenance and integration within the vehicle’s overall design.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩ -

Cummins Inc. Owners Manual for KTA38GC CM558. Bulletin Number 4960426.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.