This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

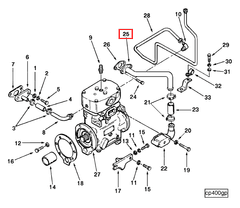

The Air Compressor Inlet Connection 3201242 is a component designed by Cummins for use in commercial trucks. This part facilitates the intake of air into the air compressor, which is a vital element of the truck’s air brake system. Its role is to ensure a steady and clean supply of air to the compressor, which in turn generates the pressurized air needed for the operation of the truck’s braking system 1.

Basic Concepts

Air compressor inlet connections are integral to the functionality of a truck’s air brake system. They allow atmospheric air to enter the compressor, where it is pressurized and stored in tanks. This pressurized air is then used to actuate the brakes. The quality and efficiency of the inlet connection can significantly influence the performance of the air compressor and, by extension, the reliability of the braking system 2.

Purpose and Function

The 3201242 Air Compressor Inlet Connection is specifically engineered to interface with Cummins air compressors. It plays a role in the air intake process by providing a secure and efficient pathway for air to enter the compressor. This connection ensures that the air entering the system is free from contaminants, which could otherwise damage the compressor or reduce its efficiency. Its design allows for seamless integration with the air compressor and the broader air brake system, contributing to the overall effectiveness of the braking mechanism 3.

Key Features

The 3201242 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding commercial truck environments. The design of the connection includes features that facilitate easy installation and maintenance, as well as provisions for filtering the incoming air to protect the compressor from debris and moisture.

Benefits

The use of the 3201242 offers several advantages. It contributes to improved efficiency of the air compressor by ensuring a clean and steady air supply. The connection’s robust construction and design enhance the reliability of the air brake system, providing consistent performance under various operating conditions. Additionally, its compatibility with Cummins air compressors ensures seamless integration and optimal function within the specified systems.

Installation Process

Installing the 3201242 requires adherence to best practices to ensure proper function and longevity. The process involves disconnecting the old inlet connection, cleaning the area to remove any debris or old sealant, and then attaching the new connection. It is important to follow the manufacturer’s guidelines for torque specifications when tightening connections to avoid over-tightening, which can damage the component, or under-tightening, which can lead to leaks.

Common Issues and Troubleshooting

Frequent problems with air compressor inlet connections can include leaks, contamination of the air supply, and connection failure due to wear or corrosion. Troubleshooting steps may involve inspecting the connection for signs of damage or wear, checking for proper torque on all connections, and ensuring that the air filter is clean and functioning correctly. Solutions may range from simple cleaning and re-torquing to replacement of the connection or associated components.

Maintenance Tips

To ensure the longevity and optimal performance of the 3201242, routine maintenance practices are recommended. These include regular inspection for signs of wear or damage, ensuring that all connections are properly torqued, and maintaining the cleanliness of the air filter. Additionally, following the manufacturer’s recommended maintenance schedule for the air compressor and brake system can help prevent issues related to the inlet connection.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial transportation.

Application in Cummins Engines

K19 Series

The K19 series engines are known for their robust design and high performance, often used in heavy-duty applications. The Air Compressor Inlet Connection 3201242 fits perfectly within this series, providing a reliable interface that supports the engine’s demanding operational requirements. This connection ensures that the air compressor can efficiently supply compressed air to the engine, enhancing overall performance and efficiency.

Other Cummins Engines

Beyond the K19 series, the Air Compressor Inlet Connection 3201242 is also compatible with a range of other Cummins engines. This versatility makes it a valuable component for maintaining and upgrading various engine models. Its design ensures a secure and leak-free connection, which is essential for the proper functioning of the air compressor system.

Importance of the Connection

The proper functioning of the air compressor inlet connection is crucial for several reasons:

- Efficiency: Ensures that the air compressor can deliver air to the engine at the required pressure and flow rate.

- Reliability: Provides a secure connection that minimizes the risk of air leaks, which can lead to performance issues and reduced efficiency.

- Compatibility: Designed to fit seamlessly with various Cummins engine models, making it a versatile choice for maintenance and upgrades.

By integrating the Air Compressor Inlet Connection 3201242 into Cummins engines, users can expect enhanced performance, reliability, and ease of maintenance. This component is a testament to Cummins’ commitment to quality and durability in their engine components.

Role of Part 3201242 Air Compressor Inlet Connection in Engine Systems

The part 3201242 Air Compressor Inlet Connection is integral to the seamless operation of various engine systems. It serves as the primary interface between the air compressor and the air supply tube, ensuring a secure and efficient transfer of compressed air.

Integration with the Air Compressor

When the air compressor generates compressed air, the 3201242 Air Compressor Inlet Connection is the first point of contact for this airflow. It is designed to withstand the pressure exerted by the compressor, maintaining a tight seal to prevent any loss of air. This ensures that the full force of the compressed air is available for subsequent processes within the engine system.

Connection to the Air Supply Tube

Following its role with the air compressor, the 3201242 component transitions the compressed air into the air supply tube. This tube is responsible for directing the air to various parts of the engine that require it, such as the pneumatic tools or the air-assisted fuel injection system. The secure connection provided by the 3201242 part is essential for maintaining the integrity of the air supply, ensuring that there are no leaks or reductions in pressure that could affect engine performance.

Ensuring Efficient Airflow

The efficiency of the airflow from the compressor to the supply tube is paramount. The 3201242 Air Compressor Inlet Connection is engineered to facilitate a smooth transition, minimizing turbulence and ensuring that the compressed air reaches its destination without unnecessary loss of pressure or efficiency. This is particularly important in high-performance engines where even minor inefficiencies can have significant impacts on overall engine performance.

Supporting Engine Components

Beyond its direct role in the air compressor and supply tube systems, the 3201242 part indirectly supports other engine components that rely on a consistent and reliable supply of compressed air. This includes components such as the air-assisted fuel injection system, pneumatic actuators, and various maintenance tools that are powered by compressed air. The reliable connection provided by the 3201242 part ensures that these components receive the air they need to function correctly, contributing to the overall efficiency and reliability of the engine system.

Conclusion

The 3201242 Air Compressor Inlet Connection is a critical component in the operation of Cummins engines and the broader air brake system in commercial trucks. Its design and functionality ensure a secure, efficient, and contaminant-free supply of air to the compressor, which is essential for the reliable operation of the braking system. Proper installation, maintenance, and understanding of its role within the engine system are key to maximizing its benefits and ensuring the longevity and performance of the engine and braking system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.