This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

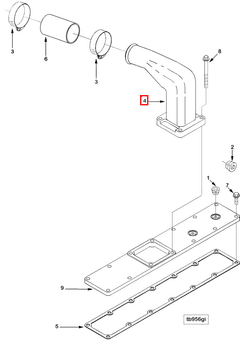

The Cummins 3282706 Air Inlet Pipe is a component designed for use in commercial trucks. Its purpose is to facilitate the flow of air into the engine, which is vital for combustion and overall engine performance. The significance of this part lies in its role in ensuring that the engine receives a consistent and clean air supply, which contributes to efficient operation and longevity of the engine 1.

Basic Concepts of Air Inlet Pipes

An air inlet pipe is a conduit that directs air from the outside environment into the engine’s intake system. Its function is to provide a pathway for air to travel from the air filter to the turbocharger or directly to the engine’s intake manifold. The air inlet pipe contributes to overall engine performance by ensuring that the air entering the engine is free from contaminants and is at the correct temperature and pressure for optimal combustion 2.

Purpose of the 3282706 Air Inlet Pipe

The 3282706 Air Inlet Pipe plays a role in the operation of a truck by facilitating the flow of air to the engine. It is designed to connect the air filter to the turbocharger or intake manifold, ensuring that the air entering the engine is clean and at the appropriate conditions for efficient combustion. This part helps maintain the engine’s performance by providing a reliable air supply 3.

Key Features

The Cummins 3282706 Air Inlet Pipe is constructed from durable materials that are resistant to the high temperatures and pressures found in a truck’s engine compartment. Its design includes features such as reinforced joints and a smooth interior to minimize air turbulence and maximize airflow efficiency. Unique attributes of this pipe may include its ability to withstand vibrations and its compatibility with specific engine configurations 4.

Benefits

Using the Cummins 3282706 Air Inlet Pipe can lead to improved engine efficiency due to its design, which promotes a smooth and uninterrupted flow of air. The durability of the materials used in its construction contributes to a longer service life, potentially reducing the frequency of replacements. Fleet operators may experience cost savings from the enhanced performance and durability of this component 5.

Installation Process

To install the Cummins 3282706 Air Inlet Pipe, one should follow a step-by-step process that includes disconnecting the old pipe, aligning the new pipe with the air filter and intake system, and securing it in place with the appropriate clamps or fasteners. Tools required may include wrenches and possibly a torque wrench to ensure proper tightening. It is important to verify that the pipe is securely fitted to prevent air leaks, which could affect engine performance 6.

Troubleshooting Common Issues

Common problems with the Cummins 3282706 Air Inlet Pipe may include leaks or blockages. To address these issues, one should inspect the pipe for signs of damage or wear, check the connections for proper sealing, and ensure that there are no obstructions in the air path. If a leak is detected, the pipe may need to be resealed or replaced. Blockages can often be cleared by cleaning the air filter and inspecting the pipe for any debris 7.

Maintenance Tips

Routine maintenance practices for the Cummins 3282706 Air Inlet Pipe include regular cleaning to remove any accumulated dirt or debris, inspecting the pipe for signs of wear or damage, and following the manufacturer’s recommended replacement schedule. Keeping the pipe in good condition will help ensure consistent engine performance and longevity 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses.

Compatibility with Cummins Engines

The Air Inlet Pipe part 3282706 is specifically engineered to fit various Cummins engines, including but not limited to:

- 6B5.9 Series: This part is compatible with the 6B5.9 engine series, ensuring a seamless fit and function within the engine’s air intake system. The design of this pipe is tailored to meet the specific airflow requirements of the 6B5.9 engine, enhancing its performance and reliability.

Installation and Functionality

When installed, the Air Inlet Pipe part 3282706 connects the engine’s air filter housing to the turbocharger or intake manifold, depending on the engine configuration. This connection is crucial for maintaining the integrity of the air intake system, preventing air leaks, and ensuring that the engine operates at peak efficiency.

The pipe is typically made from durable materials that can withstand the high temperatures and pressures within the engine compartment. Its design also includes features that minimize turbulence and resistance, facilitating smooth airflow and reducing the strain on the engine’s components.

Importance in Engine Performance

The Air Inlet Pipe part 3282706 plays a vital role in the overall performance of the engine. By providing a reliable and efficient pathway for air to enter the engine, it helps to maintain optimal combustion, reduce emissions, and improve fuel economy. This part is essential for ensuring that the engine operates smoothly and efficiently, contributing to the longevity and reliability of the engine.

Role of Part 3282706 Air Inlet Pipe in Engine Systems

The part 3282706 Air Inlet Pipe is integral to the efficient operation of various engine systems, particularly in arrangements involving turbochargers.

In turbocharged engine setups, the Air Inlet Pipe facilitates the smooth and uninterrupted flow of air from the atmosphere into the engine’s intake system. This is essential for maintaining optimal air-fuel ratios, which are vital for combustion efficiency and overall engine performance.

The pipe’s design ensures that the air entering the turbocharger is clean and free from contaminants, which helps in preserving the turbocharger’s longevity and efficiency. Additionally, the Air Inlet Pipe often incorporates features such as resonance chambers or sound dampening materials to reduce noise levels produced by the airflow, contributing to a quieter engine operation.

Furthermore, in engine arrangements where multiple cylinders or banks are present, the Air Inlet Pipe may be designed to distribute air evenly across all intake ports, ensuring uniform air distribution and consistent performance across the engine.

Conclusion

In summary, the part 3282706 Air Inlet Pipe plays a significant role in enhancing the performance, efficiency, and durability of engine systems, particularly in turbocharged applications.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Operation and Maintenance Manual, Bulletin Number 5504282, Cummins Inc.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Operation and Maintenance Manual, Bulletin Number 5504282, Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.