This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

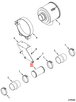

The Cummins 3285142 Air Inlet Tube is a critical component in heavy-duty trucks, designed to facilitate the intake of air into the engine, which is essential for combustion 1. This part ensures that the engine receives a consistent and adequate supply of air, which is necessary for optimal performance and efficiency 2.

Function and Operation

The Air Inlet Tube directs ambient air into the engine’s intake system, channeling it from the outside environment to the turbocharger or directly to the engine’s intake manifold 3. This part maintains optimal airflow by providing a direct and unobstructed path for air to travel, which is vital for the engine’s combustion process 4. Proper airflow ensures that the air-fuel mixture is correct, contributing to efficient engine operation.

Key Features

The Cummins 3285142 Air Inlet Tube is constructed with durability and performance in mind. It is made from materials resistant to the harsh conditions found in heavy-duty truck environments, such as high temperatures and vibrations 5. The tube’s design includes reinforced sections and a smooth interior to reduce air turbulence, enhancing its ability to withstand these conditions and contributing to the overall reliability and longevity of the component 6.

Benefits

Using the Cummins 3285142 Air Inlet Tube offers several advantages. It contributes to improved engine efficiency by ensuring a steady airflow, which can lead to better fuel economy 7. Additionally, by providing clean and unobstructed air to the engine, it helps reduce wear on engine components, potentially extending the engine’s lifespan 8. The enhanced airflow also supports the engine’s power output, contributing to the truck’s overall performance 9.

Installation Process

Installing the Cummins 3285142 Air Inlet Tube requires careful attention to ensure a secure and effective fit. The process involves disconnecting the old tube, aligning the new tube with the engine’s intake system, and securing it in place with the appropriate fasteners 10. It is important to follow the manufacturer’s guidelines to avoid damage to the tube or the engine and to ensure that the tube is properly sealed to prevent air leaks 11.

Maintenance and Care

To prolong the lifespan of the Cummins 3285142 Air Inlet Tube and ensure continued optimal performance, routine maintenance is recommended. This includes regular inspection for signs of wear or damage, cleaning the tube to remove any debris that may obstruct airflow, and replacing the tube if it becomes compromised 12. Adhering to these maintenance practices can help maintain the efficiency and reliability of the engine 13.

Troubleshooting Common Issues

Common issues with the Air Inlet Tube may include leaks or blockages, which can affect engine performance. If a leak is suspected, the tube should be inspected for cracks or loose connections. Blockages can be identified by a reduction in engine power or unusual noises and may require cleaning or replacement of the tube 14. Addressing these issues promptly can help maintain the engine’s efficiency and prevent further damage 15.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a diverse product lineup, Cummins is recognized for its commitment to quality and performance in the automotive industry 16. The 3285142 Air Inlet Tube is part of Cummins’ extensive range of components designed to enhance the performance and reliability of heavy-duty engines.

Cummins Air Inlet Tube 3285142 Compatibility

The Cummins Air Inlet Tube part number 3285142 is designed to fit seamlessly with a variety of engine models. This part is crucial for ensuring that the engine receives a steady and clean air supply, which is essential for optimal performance and efficiency 17.

Compatible Engines

-

6B5.9 and G8.3 Engines

The Air Inlet Tube 3285142 is compatible with both the 6B5.9 and G8.3 engines. These engines benefit from the precise fit and quality construction of this part, which helps maintain the integrity of the air intake system 18.

-

GTA8.3 CM558 Engine

The GTA8.3 CM558 engine also utilizes the Air Inlet Tube 3285142. This part is engineered to meet the specific requirements of this engine model, ensuring that it operates smoothly and efficiently 19.

By using the Cummins Air Inlet Tube 3285142, engine owners can be confident that their engines will receive the necessary airflow, contributing to overall performance and longevity 20.

Role of Part 3285142 Air Inlet Tube in Engine Systems

The 3285142 Air Inlet Tube is an essential component in the air intake system of various engine setups. Its primary function is to facilitate the smooth and efficient transfer of air from the air cleaner to the engine’s intake manifold 21. This tube ensures that the air, which has been filtered by the air cleaner, reaches the engine without any obstructions or leaks.

In the context of the air intake system, the 3285142 Air Inlet Tube connects the air cleaner to the intake manifold. This connection is vital for maintaining the integrity of the airflow, ensuring that the engine receives a consistent supply of clean air 22. The tube’s design allows it to withstand the pressures and temperatures associated with engine operation, providing a reliable pathway for air to travel from the cleaner to the engine.

The efficiency of the air intake system directly impacts the engine’s performance. By ensuring a steady and unobstructed flow of air, the 3285142 Air Inlet Tube helps optimize combustion within the engine 23. This, in turn, contributes to better fuel efficiency, enhanced power output, and reduced emissions 24.

Conclusion

In summary, the 3285142 Air Inlet Tube plays a significant role in the air intake system by providing a secure and efficient connection between the air cleaner and the intake manifold, thereby supporting overall engine performance 25.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.