This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

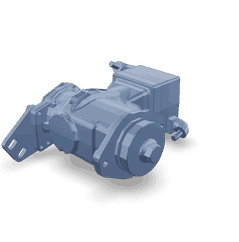

The Cummins Single Cylinder Air Compressor, part number 3357662, is a specialized component designed to provide compressed air for various systems in commercial trucks. Its purpose is to ensure the efficient operation of pneumatic systems, including braking and suspension, which are vital for the safe and reliable performance of trucks. This compressor is significant in the operation of commercial trucks as it contributes to the overall functionality and safety of the vehicle.

Basic Concepts of Single Cylinder Air Compressors

Single cylinder air compressors operate on the principle of converting mechanical energy into pneumatic energy. They consist of a cylinder, piston, intake valve, exhaust valve, and a drive mechanism. As the piston moves within the cylinder, it draws in air through the intake valve. Upon compression, the air is expelled through the exhaust valve into a storage tank. These compressors are utilized across various industries for their simplicity and efficiency in providing compressed air for different applications 1.

Purpose and Role in Truck Operation

The 3357662 Single Cylinder Air Compressor plays a role in the operation of a truck by providing the necessary compressed air for critical systems. It supplies air to the braking system, ensuring that the brakes engage effectively. Additionally, it supports the air suspension system, contributing to a smoother ride and better load handling. The compressor also powers other pneumatic applications within the truck, enhancing overall performance and safety 2.

Key Features

The 3357662 Single Cylinder Air Compressor is characterized by its robust design and high-quality construction materials. It features a durable cylinder and piston assembly, designed to withstand the rigors of continuous operation. The compressor also includes precision-machined components to ensure efficient air compression. Unique attributes such as its compact size and lightweight design enhance its performance and reliability in truck applications.

Benefits

Using the 3357662 Single Cylinder Air Compressor offers several benefits. It provides improved efficiency in air compression, leading to better performance of pneumatic systems. The compressor is known for its reliability, ensuring consistent operation under various conditions. Additionally, its design contributes to enhanced overall performance of the truck, supporting critical functions such as braking and suspension 3.

Installation and Integration

Proper installation of the 3357662 Single Cylinder Air Compressor involves several steps. Initially, the truck’s engine compartment must be prepared to accommodate the compressor. This includes ensuring adequate space and securing all necessary mounting points. The compressor is then mounted using the provided brackets and secured with appropriate fasteners. Connections to the air intake, exhaust, and electrical systems are established, following the manufacturer’s guidelines to ensure proper integration into the truck’s systems.

Troubleshooting and Maintenance

Common issues with the 3357662 Single Cylinder Air Compressor may include leaks, unusual noises, or insufficient air pressure. Troubleshooting involves checking for loose connections, inspecting seals and gaskets for wear, and ensuring the compressor is receiving adequate lubrication. Regular maintenance practices include cleaning the compressor, checking for wear on moving parts, and ensuring all connections are secure. Adhering to these practices helps maintain optimal performance and longevity of the compressor 4.

Performance Optimization

To optimize the performance of the 3357662 Single Cylinder Air Compressor, several strategies can be employed. Regular maintenance, as previously discussed, is fundamental. Additionally, ensuring the compressor is operating within its specified parameters can enhance efficiency. Upgrades such as improved filtration systems or more efficient drive mechanisms can further optimize performance. Operational best practices, including monitoring air pressure and system demands, contribute to the compressor’s effective operation.

Safety Considerations

When working with the 3357662 Single Cylinder Air Compressor, several safety considerations must be observed. Proper handling of the compressor during installation and maintenance is crucial to prevent injuries. Ensuring all connections are secure and systems are depressurized before servicing reduces the risk of accidents. Additionally, following manufacturer guidelines for maintenance and operation helps ensure safe and reliable performance of the compressor.

Environmental Impact

The use of the 3357662 Single Cylinder Air Compressor has environmental considerations, primarily related to energy efficiency and emissions. The compressor’s efficient operation contributes to reduced fuel consumption, lowering the overall environmental impact. Additionally, proper maintenance and efficient operation help minimize emissions associated with the compressor’s use. Sustainability practices, such as recycling components and using environmentally friendly lubricants, further support eco-friendly operations.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient power solutions. The company’s mission is to make people’s lives better by powering a more prosperous world, reflecting its dedication to excellence and sustainability in the manufacturing of engines and compressors.

Compatibility of Cummins Single Cylinder Air Compressor Part 3357662

The Cummins Single Cylinder Air Compressor part number 3357662 is designed to integrate seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This part is engineered to fit within the engine architecture of the following Cummins engines:

- 6B5.9 Series

The 6B5.9 engine series is known for its robust design and efficiency, making it a popular choice in various industrial applications. The air compressor part 3357662 is specifically tailored to complement the 6B5.9 engine’s operational requirements, providing essential air support for the engine’s functions.

When installed, the air compressor part 3357662 interfaces with the engine’s air intake system, ensuring that the engine receives the necessary compressed air for optimal combustion and performance. This integration is critical for maintaining the engine’s efficiency and longevity, as it supports the engine’s air management systems.

The compatibility of the air compressor part 3357662 with the 6B5.9 engine series is a result of meticulous engineering and design, ensuring that the part fits perfectly within the engine’s framework. This compatibility is further enhanced by the use of high-quality materials and precision manufacturing processes, which guarantee that the part will perform reliably under various operating conditions.

Role of Part 3357662 Single Cylinder Air Compressor in Engine Systems

The Part 3357662 Single Cylinder Air Compressor is an essential component in various engine systems, primarily responsible for generating compressed air that powers multiple functions within the engine.

Fuel Injection Systems

In fuel injection systems, the compressed air from the air compressor is utilized to atomize fuel, ensuring a fine mist that enhances combustion efficiency. This leads to improved fuel economy and reduced emissions.

Pneumatic Actuators

Pneumatic actuators rely on compressed air to operate. The air compressor provides the necessary pressure to move these actuators, which in turn control various engine components such as valves and throttle bodies.

Brake Systems

In brake systems, particularly those found in heavy-duty vehicles, the air compressor supplies the air pressure required for the brake actuators. This ensures reliable and responsive braking performance under various conditions.

Suspension Systems

Some advanced suspension systems use air springs that require a consistent supply of compressed air. The air compressor maintains the pressure in these air springs, allowing for adjustable ride height and improved handling.

Cabin Pressurization

In certain applications, such as in construction or mining equipment, the air compressor is used to pressurize the cabin. This not only enhances comfort but also provides a safer working environment by keeping out dust and debris.

Tool Operation

Many engine systems are equipped with pneumatic tools that require a steady supply of compressed air. The air compressor ensures these tools operate efficiently, reducing downtime and increasing productivity.

Cooling Systems

In some engine cooling systems, compressed air is used to enhance the efficiency of heat exchangers. The air compressor provides the necessary airflow to dissipate heat more effectively, maintaining optimal engine temperature.

Emission Control Systems

Modern emission control systems may use compressed air for various functions, including the operation of valves and actuators in exhaust gas recirculation (EGR) systems. The air compressor ensures these components function correctly, helping to meet stringent emission standards.

Conclusion

By understanding the multifaceted role of the Part 3357662 Single Cylinder Air Compressor, engineers and mechanics can better appreciate its importance in maintaining the overall performance and reliability of engine systems. This compressor is integral to the efficient operation of various systems within commercial trucks, contributing to safety, performance, and reliability.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.