This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3424562 Air Transfer Tube is a component designed for use in commercial trucks. It serves a specific function within the truck’s air system, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and operation is key to maintaining the air system’s integrity and ensuring the truck operates smoothly.

Basic Concepts of Air Transfer Tubes

An Air Transfer Tube is a conduit that facilitates the movement of air within a truck’s air system. It plays a role in directing air to various components that require it for operation, such as the brakes and suspension systems. The efficiency of air flow through these tubes is vital for the proper functioning of these systems, as it ensures that air is delivered where needed, at the correct pressure and volume 1.

Purpose of the Cummins 3424562 Air Transfer Tube

The Cummins 3424562 Air Transfer Tube is engineered to direct and regulate air flow within the truck’s air system. It connects different parts of the system, allowing for the efficient transfer of air. This component ensures that air reaches its destination without unnecessary loss of pressure or volume, which is important for the consistent performance of air-dependent systems.

Key Features

The Cummins 3424562 Air Transfer Tube is characterized by its robust design and the materials used in its construction. It is made from durable materials that can withstand the pressures and temperatures encountered within a truck’s air system. Its design includes features that enhance its performance, such as smooth internal surfaces to minimize air resistance and secure connection points to prevent leaks.

Benefits

The use of the Cummins 3424562 Air Transfer Tube offers several advantages. It contributes to improved air system efficiency by ensuring that air is directed and regulated effectively. The tube’s durable construction and reliable performance help to reduce the need for frequent replacements, offering long-term value. Additionally, its design helps to maintain system reliability by preventing air leaks and ensuring consistent air flow.

Installation and Integration

Proper installation of the Cummins 3424562 Air Transfer Tube is important for its effective operation. It should be integrated into the truck’s air system with attention to detail, ensuring that all connections are secure and that the tube is correctly positioned. Preparations may include cleaning the installation area and checking for any obstructions that could affect performance.

Troubleshooting and Maintenance

To maintain optimal performance, it is important to be aware of common issues that may arise with the Cummins 3424562 Air Transfer Tube. Regular inspections can help identify potential problems, such as leaks or blockages, early on. Maintenance tips include keeping the tube and its connections clean and free from debris, and replacing the tube if it shows signs of wear or damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient components for a wide range of applications, including commercial trucks. The company’s focus on customer satisfaction and technological advancement underscores its position in the industry.

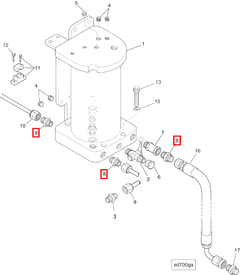

Role of Part 3424562 Air Transfer Tube in Engine Systems

The 3424562 Air Transfer Tube is a component in the efficient operation of various engine systems. It facilitates the movement of air between different parts of the engine, ensuring optimal performance and reliability.

Air Assembly Tank

In conjunction with the air assembly tank, the 3424562 Air Transfer Tube plays a significant role in maintaining the required air pressure within the system. The tube transports compressed air from the tank to other components, ensuring a consistent supply of pressurized air necessary for the engine’s operation. This helps in maintaining the efficiency of the air-fuel mixture, which is vital for combustion processes 2.

Air Shutdown Device

The integration of the 3424562 Air Transfer Tube with the air shutdown device is designed to enhance safety and control within the engine system. The tube delivers air to the shutdown device, allowing it to function correctly during emergency situations or routine operations. This ensures that the engine can be safely and effectively shut down when necessary, preventing potential damage or unsafe conditions.

Device

When connected to various devices within the engine system, the 3424562 Air Transfer Tube ensures that these devices receive the necessary air supply to operate efficiently. Whether it’s for cooling, cleaning, or actuating purposes, the consistent airflow provided by the tube is essential for the proper functioning of these devices. This reliability in air delivery helps maintain the overall performance and longevity of the engine components.

Air Shutdown

The air shutdown mechanism relies on the 3424562 Air Transfer Tube to deliver air precisely when needed. This component ensures that the shutdown process is smooth and effective, protecting the engine from overpressure or other hazardous conditions. The tube’s role in this system is to provide a reliable air pathway that can be quickly engaged or disengaged as required by the shutdown protocol.

Conclusion

Overall, the Cummins 3424562 Air Transfer Tube is a key element in the intricate network of air management within engine systems, ensuring that all connected components receive the air they need to function optimally. Its robust design, durable construction, and reliable performance make it an essential component for the efficient operation of commercial trucks and various engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.