This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

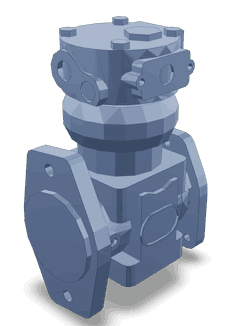

The Cummins 3558038 Air Compressor is a critical component designed for use in commercial trucks. It ensures the efficient operation of various truck systems, particularly those reliant on compressed air. This compressor is essential for maintaining the functionality of braking systems, pneumatic tools, and other air-operated components within commercial vehicles.

Basic Concepts of Air Compressors

An air compressor converts power into potential energy stored in pressurized air. By compressing air, the compressor increases its pressure, which can then be used to perform work. In commercial trucks, air compressors are vital for operating systems that require a steady supply of compressed air, such as braking systems and pneumatic tools 1.

Purpose of the Cummins 3558038 Air Compressor

The Cummins 3558038 Air Compressor is integral to the operation of a truck by providing the necessary compressed air for various systems. It is particularly important for the braking system, ensuring that brakes can be applied effectively and reliably. Additionally, it supports the operation of pneumatic tools and other air-operated components, contributing to the overall efficiency and safety of truck operations.

Key Features

The Cummins 3558038 Air Compressor is characterized by its robust design and high build quality. It incorporates advanced technological features that enhance its performance and reliability. These features include precision engineering, durable materials, and efficient compression mechanisms, all of which contribute to its effectiveness in commercial truck applications.

Benefits

Using the Cummins 3558038 Air Compressor offers several advantages. It provides improved efficiency in truck operations by ensuring a consistent supply of compressed air. Its reliable performance contributes to the safety and effectiveness of the braking system and other air-operated components. Additionally, the compressor’s design enhances the overall performance of the truck, making it a valuable component for commercial vehicle operators.

Installation and Integration

Proper installation and integration of the Cummins 3558038 Air Compressor into a truck’s system require attention to detail and adherence to manufacturer guidelines. It is important to ensure that all connections are secure and that the compressor is compatible with the truck’s existing systems. Consideration should be given to the compressor’s location within the truck to optimize its performance and efficiency.

Troubleshooting Common Issues

Common issues with the Cummins 3558038 Air Compressor may include leaks, insufficient air pressure, or compressor failure. Troubleshooting these problems involves checking for leaks in the system, ensuring that all connections are secure, and verifying that the compressor is functioning correctly. Regular maintenance and inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3558038 Air Compressor. This includes checking for leaks, ensuring that all connections are tight, and performing routine inspections of the compressor and its components. Following the manufacturer’s maintenance schedule and guidelines will help keep the compressor in good working condition.

Performance Enhancements

There are potential upgrades or modifications that can be made to the Cummins 3558038 Air Compressor to enhance its performance and efficiency. These may include installing higher-quality filters, upgrading to more efficient compression mechanisms, or incorporating advanced monitoring systems to track the compressor’s performance. Such enhancements can contribute to improved truck operations and increased reliability.

Safety Considerations

When working with the Cummins 3558038 Air Compressor, it is important to follow safety guidelines and precautions to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring that the compressor is properly installed and maintained, and following all manufacturer safety recommendations. Adhering to these safety practices will help protect both the equipment and the individuals working with it.

Cummins Company Overview

Cummins Inc. is a leading manufacturer of diesel and natural gas engines, as well as related technologies. With a strong reputation in the industry, Cummins is known for its commitment to quality and innovation. The company’s air compressors, including the Cummins 3558038, are designed with precision engineering and advanced technology to meet the demanding requirements of commercial truck operations. Cummins’ dedication to excellence is evident in its products, which are trusted by professionals worldwide 2.

Understanding the Integration of Part 3558038 Air Compressor in Engine Systems

The 3558038 air compressor is a critical component in various engine systems, facilitating the delivery of pressurized air necessary for optimal engine performance. Its integration with other components ensures efficient operation and maintenance of the engine’s overall health.

Compressor System Integration

In the compressor system, the 3558038 air compressor works in tandem with the turbocharger and intercooler. The compressor draws in ambient air and compresses it, increasing its pressure and density. This high-pressure air is then fed into the intercooler, where it is cooled before entering the engine’s intake manifold. The cooled, dense air enhances combustion efficiency, leading to improved power output and fuel economy.

Air Intake System Coordination

Within the air intake system, the 3558038 air compressor plays a significant role by providing a consistent supply of pressurized air. This air passes through the air filter, which removes contaminants, ensuring that only clean air enters the engine. The mass airflow sensor (MAF) measures the amount of air entering the engine, allowing the engine control unit (ECU) to adjust the fuel injection accordingly for optimal air-fuel ratio.

Fuel Injection System Synergy

The pressurized air supplied by the 3558038 air compressor directly influences the fuel injection system. With denser air available, the ECU can inject more fuel, enhancing combustion efficiency. This synergy between the air compressor and fuel injection system ensures that the engine operates within its performance parameters, delivering power while maintaining efficiency.

Exhaust System Interaction

The efficiency of the 3558038 air compressor also impacts the exhaust system. Improved combustion results in cleaner exhaust gases, reducing the load on the catalytic converter and other exhaust treatment components. This interaction ensures that the engine meets emission standards while maintaining performance.

Engine Control Unit (ECU) Communication

The 3558038 air compressor’s performance is monitored by the ECU through various sensors, including the boost pressure sensor and the MAF sensor. The ECU uses this data to make real-time adjustments to the air-fuel mixture and ignition timing, ensuring that the engine operates efficiently under varying conditions.

Maintenance and Monitoring

Regular maintenance of the 3558038 air compressor is essential to ensure its efficient operation. This includes checking for leaks in the intake system, ensuring the air filter is clean, and monitoring the compressor’s performance through diagnostic tools. Proper maintenance ensures that the compressor continues to deliver the required pressurized air, supporting the engine’s performance and longevity.

Conclusion

The Cummins 3558038 Air Compressor is a vital component in commercial truck operations, ensuring the efficient and reliable performance of various systems reliant on compressed air. Its robust design, advanced features, and integration with engine systems contribute to improved efficiency, safety, and overall performance of the truck. Regular maintenance and adherence to safety guidelines are essential to maximize the compressor’s longevity and effectiveness.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.