This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

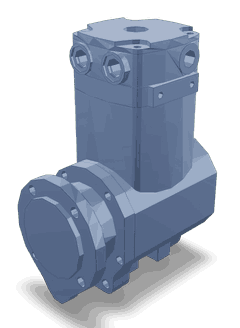

The Cummins 3558112 Air Compressor is a critical component in commercial truck operations. It provides the necessary compressed air for various systems within the truck, ensuring efficient and reliable performance. This compressor is essential for the functionality of the braking system, pneumatic tools, and other air-operated components, making it a cornerstone of truck maintenance and operation.

Basic Concepts of Air Compressors

An air compressor converts power into potential energy stored in pressurized air. It works by drawing in air, compressing it, and storing it in a tank until needed. In the automotive industry, air compressors are used for various applications, including powering brakes, operating pneumatic tools, and supporting air suspension systems. The efficiency and reliability of these compressors are vital for the smooth operation of vehicles, particularly in commercial trucking where consistent performance is required 1.

Role of the 3558112 Air Compressor in Truck Operations

The Cummins 3558112 Air Compressor plays a significant role in the operation of commercial trucks. It provides the compressed air necessary for the braking system, ensuring that brakes engage quickly and effectively. Additionally, it powers pneumatic tools used for maintenance and other tasks, as well as supports air-operated components such as suspension systems and auxiliary equipment. The consistent supply of compressed air is vital for the safe and efficient operation of these systems 2.

Key Features

The Cummins 3558112 Air Compressor is known for its robust build quality, high efficiency, and durability. It is constructed with premium materials to withstand the rigors of commercial truck use. The compressor features an efficient design that maximizes air output while minimizing energy consumption. Additionally, it includes unique design elements such as advanced sealing technology to prevent leaks and ensure consistent performance over time.

Benefits of Using the Cummins 3558112 Air Compressor

Using the Cummins 3558112 Air Compressor offers several advantages. It provides improved performance through reliable and consistent air supply, enhancing the efficiency of the braking system and pneumatic tools. The compressor’s durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, its efficient design contributes to overall fuel savings by optimizing air compression processes 3.

Installation Process

Installing the Cummins 3558112 Air Compressor involves several steps. Begin by ensuring the truck’s engine is turned off and the system is depressurized. Remove the old compressor, taking note of any mounting points and connections. Install the new compressor, securing it in place and connecting all necessary hoses and electrical components. Finally, test the system to ensure proper operation and check for any leaks.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3558112 Air Compressor. This includes checking for leaks, ensuring all connections are secure, and monitoring the compressor’s performance regularly. It is also important to keep the compressor clean and free of debris, as well as to follow the manufacturer’s recommended service intervals for inspections and part replacements.

Troubleshooting Common Issues

Common issues with air compressors can include leaks, insufficient air pressure, and unusual noises during operation. To troubleshoot these problems, start by checking all connections for leaks and ensuring they are tight. If air pressure is low, inspect the compressor for blockages or damage. Unusual noises may indicate worn components or misalignment, which should be addressed by a professional technician.

Performance Enhancements

To enhance the performance of the Cummins 3558112 Air Compressor, consider upgrades such as high-efficiency filters, improved sealing components, and regular maintenance schedules. These enhancements can help maintain optimal air pressure and ensure the compressor operates at peak efficiency. Additionally, keeping the compressor and its components in top condition will contribute to overall system reliability.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3558112 Air Compressor, it is important to follow safety guidelines. Ensure the engine is off and the system is depressurized before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injuries. Additionally, be aware of the high-pressure nature of compressed air and take precautions to avoid accidents.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the industry. The company’s focus on advanced technology and customer satisfaction ensures that its products, including the 3558112 Air Compressor, meet the highest standards of performance and reliability.

Compatibility of Cummins Air Compressor Part 3558112

The Cummins Air Compressor part number 3558112 is designed to fit a variety of Cummins engines, ensuring reliable performance across different models. Here’s a breakdown of its compatibility:

- ISM CM570, QSM11 CM570: These engines benefit from the robust design of the 3558112 air compressor, providing essential air support for their operations.

- K38, K50: These engines, known for their versatility and efficiency, are well-suited to the 3558112 air compressor, which enhances their overall performance and reliability.

- L10 GAS: The L10 GAS engine, designed for natural gas applications, integrates seamlessly with the 3558112 air compressor, ensuring optimal air delivery for its specific needs.

- M11 CELECT, M11 CELECT PLUS, M11 MECHANICAL: The M11 series engines, including the CELECT, CELECT PLUS, and MECHANICAL variants, are compatible with the 3558112 air compressor. This compatibility ensures that these engines receive the necessary air support for efficient operation.

- N14 CELECT PLUS: The N14 CELECT PLUS engine, known for its power and efficiency, is also compatible with the 3558112 air compressor, providing it with the air it needs to perform at its best.

This compatibility ensures that the 3558112 air compressor can be used across a range of Cummins engines, providing a reliable and efficient solution for air delivery needs.

Role of Part 3558112 Air Compressor in Engine Systems

The Part 3558112 Air Compressor is integral to the functionality of various engine systems, enhancing performance and efficiency. Here’s how it interacts with key components:

- Fuel Injection System: The air compressor ensures a steady supply of pressurized air, which is essential for the fuel injection system. This pressurized air aids in atomizing the fuel, leading to a more efficient combustion process. The improved air-fuel mixture results in better engine performance and reduced emissions.

- Turbocharger: When integrated with a turbocharger, the air compressor plays a significant role in boosting engine power. By compressing the intake air before it enters the turbocharger, the compressor helps the turbocharger operate more efficiently. This leads to increased airflow into the engine, allowing for higher power output without compromising engine health.

- Intercooler: The air compressor works in tandem with the intercooler to manage the temperature of the compressed air. After the air is compressed, it becomes hotter. The intercooler cools this air before it enters the engine, increasing its density. This denser air allows for more efficient combustion, enhancing overall engine performance and reliability.

- Engine Control Unit (ECU): The air compressor’s operation is often monitored and controlled by the ECU. Sensors detect the pressure and temperature of the compressed air, allowing the ECU to make real-time adjustments. This ensures optimal air-fuel ratios and maintains engine efficiency under varying conditions.

- Exhaust Gas Recirculation (EGR) System: In engines equipped with an EGR system, the air compressor assists in managing the recirculated exhaust gases. By providing a consistent flow of fresh, pressurized air, the compressor helps dilute the exhaust gases, reducing nitrogen oxides (NOx) emissions. This contributes to a cleaner and more environmentally friendly engine operation.

- Aftercooler: Similar to the intercooler, the aftercooler benefits from the air compressor by receiving pre-compressed air. The aftercooler further reduces the temperature of the air, enhancing its density and ensuring that the engine receives the coolest possible air for combustion. This leads to improved engine efficiency and longevity.

- Air Intake System: The air compressor is a key component of the air intake system, responsible for delivering a consistent and pressurized air supply to the engine. This ensures that the engine always has the necessary air volume for optimal combustion, regardless of external conditions or engine load.

- Charge Air Cooler (CAC): The CAC works in conjunction with the air compressor to cool the compressed air before it enters the engine. This cooling process increases the air’s density, allowing for more efficient combustion and higher engine performance. The CAC and air compressor together ensure that the engine operates at peak efficiency.

Conclusion

The Cummins 3558112 Air Compressor is a vital component in commercial truck operations, providing the necessary compressed air for various systems within the truck. Its robust build quality, high efficiency, and durability make it an essential part of truck maintenance and operation. Regular maintenance and proper installation are key to ensuring the longevity and optimal performance of this compressor. By understanding its role and benefits, truck operators can ensure safe and efficient operation of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.