This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3558216 Air Compressor is a vital component in the operation of commercial trucks. It is designed to provide the necessary compressed air for various systems within the vehicle, ensuring efficient and reliable performance. This compressor is integral to the functionality of the truck’s braking system, suspension, and other pneumatic systems, making it a significant part of the vehicle’s overall operation.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. It works by drawing in air, compressing it, and storing it in a tank until needed. In commercial trucks, air compressors are used to power the braking system, suspension, and other pneumatic components. The compressed air acts as a medium to transmit force, enabling these systems to function effectively 1.

Purpose of the Cummins 3558216 Air Compressor

This part plays a role in the operation of a truck by providing the compressed air needed for the braking system, suspension, and other pneumatic systems. In the braking system, it ensures that the brakes engage quickly and reliably. For the suspension, it helps maintain proper ride height and stability. Additionally, it supports other pneumatic systems that require compressed air to operate.

Key Features

The Cummins 3558216 Air Compressor is characterized by its robust design and high build quality. It features a durable construction that can withstand the demanding conditions of commercial truck operations. Unique attributes of this compressor include its efficient compression mechanism and reliable performance, which set it apart from other models in the market.

Benefits

Using this Cummins part offers several advantages. It provides improved efficiency in compressing air, ensuring that the truck’s systems receive a consistent supply of pressurized air. Its reliability means fewer downtimes and maintenance issues, contributing to overall performance. Additionally, the compressor enhances the efficiency and effectiveness of the truck’s pneumatic systems.

Installation and Integration

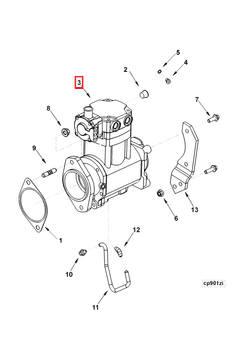

Proper installation of the Cummins 3558216 Air Compressor involves several steps to ensure it integrates seamlessly into the truck’s system. This includes preparing the mounting area, connecting the compressor to the air lines, and ensuring all electrical connections are secure. Careful consideration should be given to the compressor’s placement to avoid interference with other components and to ensure optimal airflow.

Common Issues and Troubleshooting

Common problems with the Cummins 3558216 Air Compressor may include leaks in the air lines, insufficient air pressure, or compressor failure. Troubleshooting steps involve checking for leaks, ensuring all connections are secure, and verifying that the compressor is receiving proper power. Regular inspections can help identify issues early, allowing for timely repairs and maintenance 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3558216 Air Compressor, regular maintenance is crucial. This includes inspecting the compressor and air lines for leaks, checking the compressor’s belt for wear, and ensuring the electrical connections are intact. Following a scheduled maintenance plan can help prevent issues and extend the compressor’s lifespan.

Performance Enhancements

Possible upgrades or modifications to the Cummins 3558216 Air Compressor can enhance its performance and efficiency. These may include installing a higher-capacity air tank, upgrading the compressor’s belt, or adding a filtration system to improve air quality. Such enhancements can lead to better overall system performance and reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. Founded in 1919, the company has a long-standing reputation for innovation and quality. Cummins is committed to powering a more prosperous world through its diverse product offerings and technological advancements in the engine and power generation industries 3.

Cummins Air Compressor Part 3558216 Compatibility

The Cummins air compressor part number 3558216 is designed to fit seamlessly with several models of Cummins engines, ensuring optimal performance and reliability. This part is integral to the engine’s air management system, providing the necessary compressed air for various functions.

ISB CM550

The ISB CM550 engine benefits from the 3558216 air compressor, which is engineered to meet the specific air requirements of this model. The fitment ensures efficient air delivery, contributing to the engine’s overall performance and longevity.

QSB5.9 44 CM550

Similarly, the QSB5.9 44 CM550 engine is compatible with the Cummins air compressor part 3558216. This part is tailored to integrate with the QSB5.9 44 CM550’s air system, ensuring that the engine operates at peak efficiency. The design of the 3558216 air compressor is such that it can handle the specific demands of this engine model, providing reliable and consistent performance.

Grouping of Engines

Both the ISB CM550 and QSB5.9 44 CM550 engines share a commonality in their air management systems, which allows the 3558216 air compressor to be used across these models. This compatibility is due to the standardized design and engineering principles that Cummins employs in its engine components, ensuring that parts like the 3558216 air compressor can be used interchangeably where appropriate.

Role of Part 3558216 Air Compressor in Engine Systems

The Part 3558216 Air Compressor is integral to the functionality of various engine systems. It operates by compressing air, which is then utilized in several key processes within the engine.

Turbocharging Systems

In turbocharged engines, the air compressor plays a significant role by supplying compressed air to the intake manifold. This increases the oxygen content in the combustion chamber, allowing for more fuel to be burned and thus enhancing engine power output. The compressed air also helps in reducing the temperature of the intake charge, which improves engine efficiency and performance.

Fuel Injection Systems

For engines equipped with fuel injection systems, the compressed air from the air compressor ensures a more efficient fuel-air mixture. This leads to better combustion, increased fuel economy, and reduced emissions. The precise control over the air supply allows for optimal fuel delivery, enhancing overall engine performance.

Brake Systems

In brake systems that utilize compressed air, such as those found in heavy-duty vehicles, the air compressor is responsible for maintaining the necessary air pressure. This ensures that the brakes operate effectively under various conditions, providing reliable stopping power and safety.

Pneumatic Tools and Accessories

Many engine systems incorporate pneumatic tools and accessories that require a consistent supply of compressed air. The air compressor ensures that these tools operate efficiently, contributing to maintenance and repair tasks within the engine compartment.

Cabin Pressurization (in Aircraft Engines)

For aircraft engines, the air compressor is vital for cabin pressurization. It supplies compressed air to maintain a comfortable and safe environment for passengers and crew at high altitudes. This function is essential for the overall operation and safety of the aircraft.

Aftercooling Systems

In engines with aftercooling systems, the air compressor works in conjunction with intercoolers to further cool the compressed air before it enters the combustion chamber. This process increases air density, leading to more efficient combustion and improved engine performance.

Conclusion

The Cummins 3558216 Air Compressor is a critical component in the operation of commercial trucks and various engine systems. Its robust design, efficient performance, and compatibility with multiple engine models make it a reliable choice for ensuring the functionality of pneumatic systems, turbocharging, fuel injection, and more. Regular maintenance and proper installation are essential to maximize its benefits and ensure long-term reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.