This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Air Compressor Inlet Connection, identified by Part #3558896, is a component manufactured by Cummins. It serves a significant role within the air brake system of commercial trucks. This part is integral to the system’s operation, ensuring the efficient intake of air into the compressor, which is vital for the functionality of the air brake system 1.

Basic Concepts

Air compressor inlet connections are designed to facilitate the intake of air into the compressor. Their function within the air brake system is to maintain a consistent and adequate airflow, which is necessary for the compressor to generate the required air pressure. Proper airflow is crucial for the efficient operation of the air brake system, as it directly impacts the system’s ability to deliver reliable braking performance 2.

Purpose and Functionality

The Air Compressor Inlet Connection (Part #3558896) plays a role in the operation of a truck’s air brake system by enabling the intake of air into the compressor. This part ensures that the compressor receives a steady supply of air, which is compressed and stored in the system’s air tanks. The efficient intake of air is fundamental to maintaining the necessary air pressure levels for the air brake system to function correctly 3.

Key Features

The Air Compressor Inlet Connection is characterized by its robust design and the materials used in its construction. It is engineered to withstand the demanding conditions of commercial truck operations. The part’s design includes features that enhance its performance and durability, ensuring it can effectively facilitate the intake of air into the compressor under various operating conditions.

Benefits

Utilizing the Cummins Air Compressor Inlet Connection offers several advantages. These include improved efficiency in the air intake process, enhanced reliability due to its durable construction, and compatibility with Cummins air compressors. These benefits contribute to the overall performance and longevity of the air brake system.

Installation Considerations

Proper installation of the Air Compressor Inlet Connection is vital for its effective operation. Installation procedures should follow manufacturer guidelines, which may include specific prerequisites and the use of appropriate tools. Ensuring a secure and effective fit is crucial to prevent issues such as leaks or blockages, which could impair the system’s performance.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to prolong the lifespan of the Air Compressor Inlet Connection. This includes regular inspections for signs of wear or damage. Common issues that may arise include leaks or blockages, which can be addressed through troubleshooting methods such as checking connections for tightness and ensuring the inlet is free from obstructions.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. The company has a history of innovation and quality, providing reliable solutions for the transportation sector. Cummins’ product range includes engines, filtration systems, and components like the Air Compressor Inlet Connection, which are designed to meet the rigorous demands of commercial truck operations.

Cummins Air Compressor Inlet Connection Part 3558896

The Cummins Air Compressor Inlet Connection part number 3558896 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is specifically engineered to fit the following engine models: 4B3.9 and 6B5.9.

For the 4B3.9 engine, the inlet connection is crucial in maintaining the air supply to the compressor, which is vital for the engine’s overall efficiency and operation. Similarly, in the 6B5.9 engine, this part ensures that the air compressor receives the necessary air flow, contributing to the engine’s performance and longevity.

The design of part 3558896 is such that it provides a secure and leak-proof connection, which is essential for maintaining the integrity of the air supply system. This ensures that the engine operates at peak efficiency, reducing the likelihood of air leaks that could compromise performance.

In both engine models, the inlet connection is a critical component that interfaces with other parts of the air supply system, ensuring that the air compressor functions correctly. The precision engineering of this part guarantees compatibility and ease of installation, making it a reliable choice for maintenance and repair.

Role of Part 3558896 Air Compressor Inlet Connection in Engine Systems

The part 3558896 Air Compressor Inlet Connection is integral to the efficient operation of various engine systems, particularly in ensuring the seamless integration and functionality of the air compressor assembly. This component facilitates the secure and reliable connection between the air compressor and other critical parts, optimizing the overall performance of the engine.

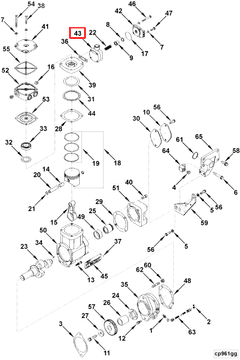

Integration with Air Compressor Assembly

The Air Compressor Inlet Connection serves as a vital interface within the air compressor assembly. It ensures that the compressed air is efficiently channeled from the compressor to other parts of the engine system. This connection is essential for maintaining the pressure and flow rates necessary for the compressor to function effectively.

Functionality with QE Unloader Serv and Kit

When integrated with the QE Unloader Serv and its associated kit, the Air Compressor Inlet Connection plays a significant role in managing the unloading process of the compressor. The unloader mechanism relies on precise air flow to operate correctly, and the inlet connection ensures that the compressed air is delivered without interruption or loss of pressure. This results in smoother operation and enhanced reliability of the unloader system.

Interaction with QE/B Head Assembly

The QE/B Head Assembly is another component where the Air Compressor Inlet Connection demonstrates its importance. By providing a stable and consistent air supply to the head assembly, it ensures that the combustion process within the engine is optimized. The inlet connection’s role in maintaining pressure integrity is key to the efficient performance of the QE/B Head Assembly, directly influencing the engine’s power output and fuel efficiency.

Overall System Efficiency

In summary, the Part 3558896 Air Compressor Inlet Connection is a foundational element in the engine system, enhancing the interaction between the air compressor, unloader service, and head assembly. Its reliable performance ensures that each component operates within its designed parameters, contributing to the overall efficiency and effectiveness of the engine.

Conclusion

The Air Compressor Inlet Connection, part number 3558896, manufactured by Cummins, is a critical component in the air brake system of commercial trucks. Its robust design and reliable functionality ensure efficient air intake into the compressor, which is essential for maintaining the necessary air pressure levels for the system to operate correctly. Proper installation, maintenance, and understanding of its role within the engine system are key to maximizing its benefits and ensuring the longevity and efficiency of the air brake system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.