This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

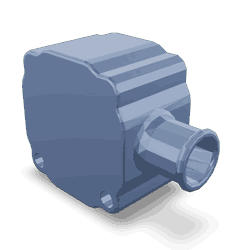

The Air Compressor Inlet Connection, identified by Part #3559002, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is integral to the functionality of heavy-duty trucks, particularly in their air brake systems. Understanding its role and significance can provide valuable insights into the overall performance and reliability of these vehicles.

Basic Concepts

Air compressor inlet connections serve as the gateway for air intake within the air brake system of a truck. The fundamental principle behind these connections is to facilitate the smooth and efficient intake of air into the compressor. This air intake is vital for the compressor’s operation, as it directly influences the generation of compressed air, which is essential for the functioning of the air brake system. The efficiency of this intake process can significantly impact the overall performance of the braking system 1.

Purpose and Function

The 3559002 Air Compressor Inlet Connection plays a specific role in the operation of a truck by enabling the intake of air into the compressor. This part ensures that air enters the system in a controlled and efficient manner, which is crucial for the compressor’s ability to generate the necessary compressed air. By optimizing the air intake process, this connection contributes to the overall efficiency and reliability of the air brake system 2.

Key Features

The 3559002 Air Compressor Inlet Connection is characterized by several key features that enhance its performance and durability. Its design is tailored to ensure a secure and effective fit within the truck’s air compressor system. The materials used in its construction are selected for their ability to withstand the demanding conditions of heavy-duty truck operation, ensuring longevity and reliability. Additionally, any unique attributes of this part, such as specialized coatings or construction techniques, further contribute to its performance 3.

Benefits

The advantages provided by the 3559002 Air Compressor Inlet Connection include improved air flow, which enhances the efficiency of the compressor. This part also reduces the risk of contamination entering the system, which can lead to compressor damage or reduced performance. Furthermore, by ensuring a reliable and secure connection, it contributes to the overall reliability of the air brake system 4.

Installation Considerations

Proper installation of the 3559002 Air Compressor Inlet Connection is crucial for its effective operation. This process involves several steps, including ensuring the area is clean and free of debris, using the appropriate tools for a secure fit, and following manufacturer guidelines to avoid damage to the part or the compressor system. A secure and effective fit is essential for the part’s performance and the system’s reliability.

Maintenance and Troubleshooting

Routine maintenance practices can prolong the lifespan of the 3559002 Air Compressor Inlet Connection. Regular inspections for signs of wear or damage, cleaning to remove any contaminants, and ensuring all connections are secure can prevent issues from arising. Common problems may include leaks or reduced efficiency, which can often be addressed by re-securing connections or cleaning the part.

Manufacturer - Cummins

Cummins is a reputable manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a history of innovation and excellence, Cummins has established a strong reputation for reliability and performance. Their components, including the 3559002 Air Compressor Inlet Connection, are designed with a focus on durability, efficiency, and compatibility with a wide range of truck models and air compressor systems.

Cummins Air Compressor Inlet Connection Part 3559002 Compatibility

The Cummins Air Compressor Inlet Connection part number 3559002 is designed to fit a variety of Cummins engine models. This part is crucial for the proper functioning of the engine’s air compressor system, ensuring efficient air intake and pressure regulation.

Compatible Engines

- 6C8.3

- ISM CM570

- K38

- K50

- L10 GAS

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

- N14 CELECT PLUS

- QSK45 CM500

- QSK60 CM500

- QSM11 CM570

Grouping by Engine Series

-

M11 Series:

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

-

QSK Series:

- QSK45 CM500

- QSK60 CM500

-

Other Models:

- 6C8.3

- ISM CM570

- K38

- K50

- L10 GAS

- N14 CELECT PLUS

- QSM11 CM570

This part is engineered to ensure compatibility across these diverse engine models, providing a reliable connection for the air compressor inlet.

Role of Part 3559002 Air Compressor Inlet Connection in Engine Systems

The 3559002 Air Compressor Inlet Connection is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the smooth and consistent flow of air into the air compressor, ensuring optimal performance and reliability.

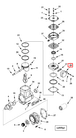

Integration with Air Compressor

The Air Compressor Inlet Connection interfaces directly with the air compressor, allowing for a secure and leak-free connection. This ensures that the compressor receives a steady supply of air, which is vital for its operation. The connection point is designed to withstand the pressures and temperatures associated with compressor operation, maintaining integrity over time.

Interaction with Compressor Head Assembly

When integrated with the compressor head assembly, the Inlet Connection plays a significant role in maintaining the pressure balance within the system. The head assembly relies on a consistent airflow to function correctly, and the Inlet Connection ensures that the air enters the system at the right pressure and volume. This is particularly important in high-demand applications where even minor fluctuations can affect performance.

Role in Air Management Systems

In air management systems, the Inlet Connection is a key component in the pathway that air takes from the environment into the engine. It works in conjunction with other components such as the air filter and intake manifold to ensure that the air entering the system is clean and at the appropriate pressure. This is essential for maintaining engine efficiency and preventing damage from contaminants.

Use in HD/M and HD/STD Head Assemblies

For HD/M (High Duty/Medium) and HD/STD (High Duty/Standard) head assemblies, the Inlet Connection is tailored to handle the specific airflow requirements of these robust systems. It ensures that the high-pressure air needed for these assemblies is delivered efficiently, contributing to the overall durability and performance of the engine.

Application in MTG Compressor Systems

In MTG (Mounted) compressor systems, the Inlet Connection is crucial for establishing a reliable air supply line. These systems often operate under varying conditions, and the Inlet Connection must be able to adapt to changes in pressure and temperature without compromising the airflow. This adaptability ensures that the MTG compressor can maintain consistent performance across different operational scenarios.

Contribution to Air Kits

Air kits, which often include a variety of components designed to enhance air flow and filtration, benefit significantly from the inclusion of the Inlet Connection. It acts as a critical junction point within the kit, ensuring that all components work in harmony to deliver the best possible air quality and pressure to the engine. This is particularly important in applications where engine performance is paramount.

Conclusion

In summary, the 3559002 Air Compressor Inlet Connection is a fundamental component in various engine systems, playing a vital role in ensuring the efficient and reliable flow of air. Its integration with other components such as the air compressor, head assembly, and air management systems underscores its importance in maintaining engine performance and longevity.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.