This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3630530 Air Inlet Tube is a critical component in commercial truck engines, designed to enhance airflow efficiency and engine performance. This part plays a significant role in the engine’s air induction system, ensuring a smooth and uninterrupted path for air from the air filter to the turbocharger or engine intake manifold 1.

Basic Concepts of Air Inlet Tubes

An air inlet tube serves as a conduit for directing air from the external environment into the engine’s intake system. The design and quality of the tube can significantly influence engine performance, including power output and fuel efficiency 2.

Purpose of the Cummins 3630530 Air Inlet Tube

The primary function of the Cummins 3630530 Air Inlet Tube is to optimize the airflow to the engine. By providing a direct and efficient pathway for air, it ensures that the engine receives the necessary volume of clean air for combustion, contributing to overall engine performance and efficiency 3.

Key Features

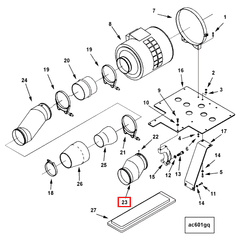

The Cummins 3630530 is characterized by its robust design and high-quality materials, which are resistant to the harsh conditions of commercial trucking environments. The tube is engineered to reduce turbulence and ensure a smooth airflow, which helps maintain engine performance. It also features specific connections and mounts for easy installation and secure fitting within the engine compartment 4.

Benefits of Using the Cummins 3630530 Air Inlet Tube

Installing this Cummins part can lead to improved engine efficiency through consistent and clean airflow. Its durable construction contributes to a longer service life, potentially leading to cost savings. Additionally, it supports fuel efficiency and reduced emissions by maintaining optimal engine performance 5.

Installation Considerations

When installing the Cummins 3630530, it is crucial to follow the manufacturer’s guidelines. This includes ensuring the engine compartment is clean and free of debris. Special tools may be required for secure installation and connection to the air filter and engine intake system. Verifying secure connections is important to prevent air leaks that could affect engine performance 6.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3630530 is recommended to ensure longevity and optimal performance. This includes inspecting the tube for wear or damage and ensuring all connections are tight. Common issues such as cracks or leaks can be addressed through repair or replacement. Regular checks help identify and resolve issues before they lead to more significant problems 7.

Cummins Overview

Cummins Inc. is renowned for its diesel engines and related technologies. The company’s commitment to innovation and quality ensures that components like the 3630530 meet stringent standards for durability and performance 8.

Compatibility

The Cummins Air Inlet Tube 3630530 is designed for compatibility with several engine models, including the K38, QSK38, CM850, and MCRS. This compatibility ensures optimal performance and reliability by providing a clean and unobstructed pathway for air to enter the engine 9.

Integration with Air Cleaner Connection

The Air Inlet Tube connects directly to the air cleaner, ensuring that the air entering the engine is clean and free from contaminants. This connection is vital for maintaining the air-fuel ratio, which is necessary for optimal engine performance and fuel efficiency 10.

Interaction with Air Cleaner

After passing through the air cleaner, where it is filtered to remove dust, dirt, and other particles, the air moves through the Air Inlet Tube. This tube acts as a conduit, guiding the filtered air towards the engine’s intake manifold. The design of the tube helps in reducing turbulence and ensuring a steady airflow, which is important for consistent engine operation 11.

Contribution to Overall Air Induction System

In the broader context of the air induction system, the Air Inlet Tube works in conjunction with other components to deliver air to the engine cylinders. Its role is to provide a direct and unobstructed path for air, minimizing any potential restrictions that could affect engine performance. By ensuring a smooth transition of air from the air cleaner to the intake manifold, the Air Inlet Tube supports the engine’s ability to operate efficiently and effectively 12.

Conclusion

The Cummins 3630530 Air Inlet Tube is a vital component in the engine’s air induction system, designed to enhance airflow efficiency and engine performance. Its robust design, compatibility with various engine models, and integration with the air cleaner system make it an essential part for maintaining optimal engine operation and reliability.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021330, Operation and Maintenance Manual.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021330, Operation and Maintenance Manual.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021330, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021330, Operation and Maintenance Manual.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.