This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3635948 Air Inlet Pipe is a component designed for use in commercial trucks. It plays a role in the engine system by facilitating the flow of air into the engine. This part is integral to maintaining optimal engine performance and efficiency in heavy-duty applications.

Basic Concepts of Air Inlet Pipes

An Air Inlet Pipe is a conduit that directs air from the outside environment into the engine’s intake system. Its function is to provide a smooth and uninterrupted flow of air to the engine, which is necessary for combustion 1. The efficiency of this airflow directly influences the engine’s performance, fuel efficiency, and emissions output.

Purpose of the Cummins 3635948 Air Inlet Pipe

The Cummins 3635948 Air Inlet Pipe is specifically engineered to enhance the airflow to the engine in commercial trucks. By ensuring a consistent and clean supply of air, it contributes to the engine’s efficiency and overall performance. This part is designed to withstand the rigors of heavy-duty use, providing reliable operation under demanding conditions.

Key Features

The Cummins 3635948 Air Inlet Pipe boasts several key features that enhance its functionality. It is constructed from durable materials to ensure longevity and resistance to the harsh conditions often encountered in commercial trucking. The design includes elements that promote efficient airflow and reduce turbulence, which can otherwise lead to engine inefficiencies. Additionally, it may incorporate unique attributes such as integrated mounting points or specific connection types that facilitate easier installation and compatibility with the engine system.

Benefits

Utilizing the Cummins 3635948 Air Inlet Pipe offers several advantages. It contributes to improved engine performance by ensuring a steady and clean air supply. The durable construction of the pipe enhances its longevity, reducing the need for frequent replacements. Moreover, its design may offer cost-effectiveness over time by promoting efficient engine operation and potentially reducing fuel consumption.

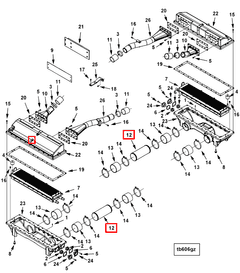

Installation Process

Installing the Cummins 3635948 Air Inlet Pipe requires careful attention to ensure proper fitting and function. The process involves disconnecting the old pipe, aligning the new pipe with the engine’s intake system, and securing it in place using the appropriate tools. It is important to follow the manufacturer’s guidelines to ensure the pipe is correctly installed and functions as intended.

Troubleshooting Common Issues

Common issues with the Cummins 3635948 Air Inlet Pipe may include leaks or reduced airflow, which can affect engine performance. Troubleshooting steps may involve inspecting the pipe for damage, ensuring all connections are secure, and checking for obstructions in the airflow path. Addressing these issues promptly can help maintain engine efficiency and performance.

Maintenance Tips

Regular maintenance of the Cummins 3635948 Air Inlet Pipe is key to ensuring its longevity and optimal performance. This includes periodic cleaning to remove any debris that may obstruct airflow, inspecting the pipe for signs of wear or damage, and replacing it as necessary according to the manufacturer’s recommendations. Proper maintenance can help prevent issues and ensure the engine operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality components that meet the demanding needs of commercial and industrial applications. The company’s focus on innovation, quality, and customer satisfaction has established it as a trusted name in the industry.

Air Inlet Pipe (Part 3635948) Compatibility with Cummins Engines

The Air Inlet Pipe, identified by the part number 3635948, is a component in the air intake system of several Cummins engines. This part is designed to ensure that clean, filtered air is directed into the engine, which is essential for optimal performance and efficiency.

QSK60 CM500 and QSK60 CM850 MCRS

The Air Inlet Pipe (3635948) is engineered to fit seamlessly with the QSK60 CM500 and QSK60 CM850 MCRS engines. These engines are known for their robust construction and high performance, making them suitable for a variety of demanding applications. The fitment of this part is critical as it ensures that the air intake system functions correctly, providing the necessary air to the engine’s combustion chambers.

The QSK60 CM500 and QSK60 CM850 MCRS engines share several design elements, which allows the Air Inlet Pipe to be a common component across both models. This commonality simplifies maintenance and repair processes, as the same part can be used for both engine types, reducing inventory needs and ensuring compatibility.

Installation and Functionality

When installing the Air Inlet Pipe (3635948) in these engines, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. The pipe must be securely attached to the engine’s intake manifold and any associated air filters to prevent air leaks, which can negatively impact engine performance and efficiency.

The Air Inlet Pipe plays a vital role in the overall air intake system by directing filtered air from the air cleaner to the engine. This ensures that the engine receives the correct air-to-fuel ratio, which is essential for efficient combustion and power output. Additionally, the pipe helps to maintain a consistent airflow, which can improve engine responsiveness and reduce wear on engine components.

Maintenance Considerations

Regular inspection and maintenance of the Air Inlet Pipe are crucial to ensure that it remains in good condition. Over time, the pipe can become damaged or develop leaks, which can affect engine performance. It is recommended to check for any signs of wear, such as cracks or holes, and replace the part if necessary to maintain optimal engine operation.

By understanding the compatibility and importance of the Air Inlet Pipe (3635948) in the QSK60 CM500 and QSK60 CM850 MCRS engines, technicians and operators can ensure that their engines run efficiently and reliably. Proper installation and maintenance of this component are key to maximizing the performance and lifespan of these powerful engines.

Role of Part 3635948 Air Inlet Pipe in Engine Systems

The part 3635948 Air Inlet Pipe is integral to the efficient operation of various engine components, particularly in turbocharged and intercooled systems. This component facilitates the smooth and controlled flow of air into the engine, ensuring optimal performance and efficiency.

Integration with the Intercooler

In systems equipped with an intercooler, the Air Inlet Pipe plays a significant role. After the air has been compressed by the turbocharger, it becomes hot and dense. The intercooler is designed to cool this air, increasing its density and allowing more oxygen to enter the combustion chamber. The Air Inlet Pipe connects the intercooler to the throttle body or the intake manifold, ensuring that the cooled, dense air is efficiently delivered to the engine. This setup enhances combustion efficiency, leading to improved power output and fuel economy 2.

Enhancing Engine Performance

By providing a direct and unobstructed path for air to travel from the intercooler to the engine, the Air Inlet Pipe minimizes turbulence and pressure drops. This results in a more consistent and reliable air supply, which is essential for maintaining engine performance under various operating conditions. The design of the pipe also helps in reducing noise and vibrations, contributing to a smoother engine operation.

Supporting Turbocharged Systems

In turbocharged engines, the Air Inlet Pipe works in conjunction with the turbocharger to deliver a higher volume of air into the combustion chamber. This increased airflow supports the turbocharger’s function of compressing air, leading to enhanced engine power and responsiveness. The pipe’s durable construction ensures it can withstand the high pressures and temperatures associated with turbocharged systems.

Facilitating Efficient Airflow

The Air Inlet Pipe is engineered to maintain a laminar flow of air, which is vital for maximizing engine efficiency. Laminar flow reduces the likelihood of air molecules colliding with the pipe walls, minimizing energy loss and ensuring that the air reaches the engine in optimal condition. This efficient airflow is particularly important in high-performance engines where every bit of power and efficiency counts.

Conclusion

The part 3635948 Air Inlet Pipe is a key component in modern engine systems, especially those featuring turbochargers and intercoolers. Its role in facilitating efficient airflow, supporting turbocharged operations, and integrating with intercoolers underscores its importance in achieving optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.