This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Air Transfer Tube, part number 3638140, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, is known for its commitment to quality and innovation in engine and powertrain technologies. This part is significant in maintaining the efficiency and safety of truck operations, particularly in the context of air brake systems and other air-dependent subsystems.

Basic Concepts of Air Transfer Tubes

An Air Transfer Tube is a conduit that facilitates the movement of compressed air within a truck’s air system. This system is vital for the operation of air brakes, suspension systems, and other pneumatic components. The tube ensures that air is efficiently distributed to various parts of the truck, contributing to the overall performance and safety of the vehicle. Proper air flow is crucial for the timely and effective operation of air brakes, which are a standard safety feature in commercial trucks 1.

Purpose of the 3638140 Air Transfer Tube

The 3638140 Air Transfer Tube serves a specific role within the air brake system and other air-dependent subsystems of a truck. It is responsible for transferring compressed air from the air compressor to the brake chambers and other components that require pressurized air to function. This ensures that the braking system operates with the necessary force and responsiveness, enhancing both the performance and safety of the vehicle 2.

Key Features

The 3638140 Air Transfer Tube is characterized by several key features that enhance its performance and durability. These include a robust material composition designed to withstand the pressures and temperatures of the air system, as well as design elements that facilitate efficient air flow. Unique attributes such as reinforced joints and corrosion-resistant coatings further contribute to its longevity and reliability in various operating conditions 3.

Benefits

The advantages provided by the 3638140 Air Transfer Tube include improved air flow efficiency, which ensures that air-dependent systems receive the necessary pressure to operate effectively. Its durability and reliability under various operating conditions make it a valuable component for commercial truck operations, contributing to the safety and efficiency of the vehicle 4.

Installation Considerations

When installing the 3638140 Air Transfer Tube, it is important to follow guidelines and best practices to ensure proper fitting and connection. Compatibility with different truck models and systems should be verified to ensure seamless integration. Steps to ensure a secure and leak-free installation include proper alignment, the use of recommended fittings, and testing the system for leaks after installation.

Troubleshooting Common Issues

Common problems associated with Air Transfer Tubes, such as leaks or blockages, can affect the performance of air-dependent systems. Troubleshooting steps to diagnose and resolve these issues include inspecting the tube for signs of wear or damage, checking connections for leaks, and ensuring that the tube is properly routed to avoid kinks or obstructions.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3638140 Air Transfer Tube. Inspection routines should include checking for signs of wear, corrosion, or damage, and cleaning procedures may be necessary to remove any debris that could obstruct air flow. Following these maintenance tips can help prevent issues and ensure the tube continues to function effectively.

Safety Considerations

When working with the 3638140 Air Transfer Tube, especially concerning the air brake system and pressurized air lines, it is important to observe safety protocols and precautions. This includes ensuring that the system is depressurized before beginning any work, using appropriate personal protective equipment, and following manufacturer guidelines for installation and maintenance to avoid accidents or injuries.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Air Transfer Tube 3638140 Compatibility

The Cummins Air Transfer Tube part number 3638140 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s air management system, facilitating the transfer of air within the engine’s components.

KTA38GC CM558 Engines

The Air Transfer Tube 3638140 is specifically engineered to integrate with the KTA38GC CM558 engines. This engine is known for its robust design and efficiency, making it a popular choice in various industrial applications. The tube’s precise fit ensures that the air flow is maintained at optimal levels, contributing to the engine’s overall performance and longevity.

Grouping of Compatible Engines

While the primary focus here is on the KTA38GC CM558 engines, it is important to note that the Air Transfer Tube 3638140 is also compatible with other Cummins engines within the same series. This compatibility is due to the standardized design and engineering principles that Cummins employs across its engine lineup. Ensuring that the tube fits correctly with these engines is crucial for maintaining the engine’s efficiency and reliability.

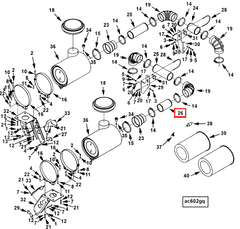

Role of Part 3638140 Air Transfer Tube in Engine Systems

The part 3638140 Air Transfer Tube is an essential component in the efficient operation of engine systems, particularly in relation to the cleaner and air components.

In the context of the cleaner component, the Air Transfer Tube facilitates the movement of air that is necessary for the cleaning process. This ensures that the cleaner operates at optimal efficiency by providing a consistent and regulated airflow. The tube’s design allows for minimal resistance, which is vital for maintaining the performance standards of the cleaner.

Regarding the air component, the Air Transfer Tube plays a significant role in managing the airflow within the engine system. It ensures that the air reaches various parts of the engine in a controlled manner, which is important for combustion efficiency and overall engine performance. The tube helps in maintaining the correct air-fuel mixture, which is essential for the smooth operation of the engine.

Additionally, the Air Transfer Tube contributes to the reduction of air leaks within the system. By providing a sealed pathway for air, it helps in maintaining the integrity of the air pressure within the engine, which is important for consistent performance.

Conclusion

In summary, the 3638140 Air Transfer Tube is integral to the functioning of both the cleaner and air components within engine systems, ensuring efficient operation and performance. Its robust design, compatibility with various Cummins engines, and role in maintaining optimal airflow make it a critical component for the safety and efficiency of commercial truck operations.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.