This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Air Shutoff Valve part number 3651938, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This Cummins part is significant in the context of truck operations as it plays a role in the engine’s air management system, contributing to the overall efficiency and safety of the vehicle 1.

Basic Concepts of Air Shutoff Valves

An Air Shutoff Valve is a component that regulates the flow of air within a truck’s air system. It operates by opening and closing to allow or restrict air passage to various parts of the engine. This valve is integral to engine management as it helps maintain optimal air pressure and flow, which are essential for efficient engine operation and performance 2.

Purpose of the 3651938 Air Shutoff Valve

This part is specifically designed to control the airflow to the engine in commercial trucks. By regulating the air supply, it helps in managing the engine’s performance under different operating conditions. The valve ensures that the engine receives the appropriate amount of air, which is necessary for combustion and overall engine efficiency.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and reliable performance in demanding commercial truck environments. The valve’s design allows for efficient air flow control, and its construction ensures resistance to wear and tear, enhancing its longevity.

Benefits

The 3651938 Air Shutoff Valve offers several advantages. It contributes to improved engine efficiency by ensuring optimal air flow. Additionally, it enhances safety by maintaining consistent air pressure within the system. The valve also plays a role in the overall performance of the truck, ensuring smooth and reliable operation.

Installation and Integration

Installing this part into a truck’s air system requires adherence to specific guidelines to ensure proper integration. It is important to follow manufacturer recommendations for installation to maintain the valve’s effectiveness and compatibility with the truck’s air system. Careful attention to detail during installation helps prevent issues and ensures the valve functions as intended.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for the longevity and optimal performance of the 3651938 Air Shutoff Valve. Common maintenance practices include checking for leaks, ensuring proper sealing, and inspecting the valve for signs of wear. Troubleshooting may involve testing the valve’s operation and addressing any issues that affect its performance.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality components. The company is known for its commitment to innovation and excellence in automotive technology. Cummins’ reputation is built on its dedication to providing reliable and efficient solutions for commercial vehicle operations, making it a trusted name in the industry 3.

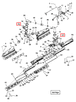

Role of Part 3651938 Air Shutoff Valve in Engine Systems

This part is an essential component in the orchestration of airflow within engine systems, ensuring optimal performance and efficiency. Its integration with various components is meticulously designed to maintain the delicate balance of air distribution and control.

Interaction with the Aftercooler

The Air Shutoff Valve works in tandem with the aftercooler to regulate the flow of air post-compression. By modulating the airflow, it ensures that the aftercooler receives a consistent and controlled stream of air, which is vital for effective cooling. This regulation helps in maintaining the desired temperature levels, which is essential for the longevity and efficiency of the engine.

Connection Points and Airflow Management

At the connection points within the engine system, the Air Shutoff Valve plays a pivotal role. It acts as a gatekeeper, allowing or restricting airflow based on the engine’s operational demands. This controlled airflow is crucial for maintaining the engine’s performance under varying conditions, ensuring that it operates within its optimal parameters.

Synergy with the Air Crossover

The Air Shutoff Valve’s collaboration with the air crossover is another testament to its importance. The air crossover facilitates the distribution of air to different parts of the engine. The valve’s ability to open or close ensures that this distribution is not only efficient but also tailored to the engine’s current needs. This dynamic control is essential for scenarios where the engine requires a sudden increase or decrease in airflow, such as during acceleration or deceleration.

Conclusion

In summary, the 3651938 Air Shutoff Valve is a linchpin in the engine’s airflow management system. Its interactions with the aftercooler, connection points, and air crossover are designed to ensure that the engine operates smoothly, efficiently, and within its designed parameters.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.