This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3683216 Air Crossover Tube is a specialized component designed for heavy-duty trucks. It plays a crucial role in the air brake system, ensuring efficient and safe operation of the vehicle’s braking mechanism. Understanding its function and importance is essential for maintaining truck safety and performance.

Basic Concepts of Air Crossover Tubes

An Air Crossover Tube is a component of the air brake system that ensures equal distribution of air pressure among different brake chambers. It connects the air supply lines from the compressor to the brake chambers, facilitating a balanced air pressure distribution. This balance is vital for synchronized brake operation, enhancing the safety and efficiency of heavy-duty truck stopping 1.

Purpose and Role in Truck Operation

The Cummins 3683216 Air Crossover Tube maintains equal air pressure between various brake chambers, improving braking performance by ensuring consistent force application across all brakes. This equalization reduces the risk of uneven braking, which could lead to skidding or loss of control 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, engineered to withstand the high pressures and temperatures of heavy-duty truck operations. Features may include reinforced joints and corrosion-resistant coatings, enhancing its durability and effectiveness in demanding environments 3.

Benefits

Using the Cummins 3683216 Air Crossover Tube offers several advantages, including improved braking efficiency, contributing to vehicle safety. Its design and materials may also reduce maintenance needs, offering potential cost savings. Enhanced performance and reliability of the air brake system can lead to a longer service life for related components 4.

Installation Process

Installing the Cummins 3683216 Air Crossover Tube involves several steps to ensure proper fitting and function. The process typically includes disconnecting the old tube, cleaning the connection points, and securely attaching the new tube using appropriate tools. Following manufacturer guidelines ensures correct installation and secure connections.

Troubleshooting Common Issues

Common issues with Air Crossover Tubes may include leaks or imbalanced air pressure. These can often be diagnosed by inspecting the tube and connections for wear or damage. Troubleshooting steps may involve tightening connections, replacing damaged sections, or replacing the tube entirely. Regular inspections can help identify potential issues before they escalate.

Maintenance Tips

Regular maintenance is recommended to ensure the longevity and optimal performance of the Cummins 3683216 Air Crossover Tube. This includes periodic inspections for wear, corrosion, or damage, and cleaning the tube and its connections to prevent buildup that may affect performance. Following the manufacturer’s maintenance schedule and guidelines will help maintain the tube’s effectiveness and contribute to the overall reliability of the air brake system.

Cummins Overview

Cummins Inc. is a renowned manufacturer known for producing diesel engines and related components. The company is recognized for its commitment to quality and innovation, reflected in its wide range of products designed for various applications, including heavy-duty trucks. Cummins’ reputation is built on its dedication to providing reliable, high-performance components that meet the demanding requirements of commercial and industrial use.

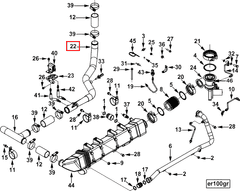

Role of Part 3683216 Air Crossover Tube in Engine Systems

The 3683216 Air Crossover Tube is integral to the efficient operation of engine systems, particularly in managing recirculation and exhaust processes.

In exhaust systems, the Air Crossover Tube ensures balanced distribution of exhaust gases between the left and right sides of the engine, maintaining optimal performance and reducing emissions. It minimizes backpressure, which can decrease engine efficiency and increase fuel consumption.

In recirculation systems, the Air Crossover Tube plays a significant role in the Exhaust Gas Recirculation (EGR) system. It ensures that recirculated exhaust gases are evenly mixed with incoming air, promoting complete combustion, lowering emissions, and contributing to smoother engine operation and improved fuel economy.

Overall, the Air Crossover Tube enhances the functionality and efficiency of both exhaust and recirculation systems within engine operations.

Conclusion

The Cummins 3683216 Air Crossover Tube is a vital component in the air brake system of heavy-duty trucks, ensuring balanced air pressure distribution and enhancing braking performance. Its robust design, coupled with the quality materials used, ensures durability and effectiveness in demanding environments. Regular maintenance and proper installation are key to maximizing its benefits and ensuring the safety and efficiency of truck operations.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.