Introduction

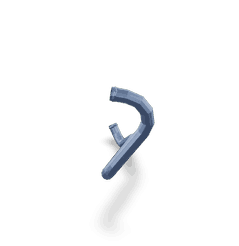

The Cummins 3686928 Air Inlet Tube is a component designed for use in commercial truck engines. Its purpose is to facilitate the efficient flow of air into the engine system, which is vital for optimal engine performance. This part is integral to the operation of turbocharged engines, where the quality and quantity of air intake directly influence engine power and efficiency 1.

Function and Operation

The Air Inlet Tube operates by directing air flow from the engine’s air filter to the turbocharger and subsequently to the intercooler. This process ensures that the air entering the engine is clean and at the appropriate temperature and pressure, which is crucial for the efficient operation of the turbocharger and the overall engine system. The tube’s design allows for a streamlined air path, minimizing turbulence and maximizing the efficiency of air delivery to the engine components 2.

Key Features

This Cummins part is constructed from high-quality materials that offer durability and resistance to the harsh conditions within a commercial truck engine environment. Its design includes features that enhance performance, such as a smooth interior to reduce air resistance and precise fittings to ensure a secure connection within the engine system. The tube’s material and construction are chosen to withstand high temperatures and pressures, ensuring long-term reliability 3.

Benefits

The use of the 3686928 can lead to improved engine efficiency due to its role in providing a consistent and optimized air flow. This can result in enhanced engine performance, including potential increases in horsepower and torque. Additionally, the tube’s durable construction contributes to the overall reliability and longevity of the engine system, reducing the need for frequent replacements or repairs.

Installation Process

Installing the Air Inlet Tube requires careful attention to ensure a proper fit and secure connection within the engine system. The process involves disconnecting the old tube, aligning the new tube with the engine’s air filter and turbocharger, and securing it in place with the appropriate fasteners. It is important to follow manufacturer guidelines to ensure that the tube is installed correctly and that all connections are tight and secure.

Maintenance and Troubleshooting

Regular maintenance of the Air Inlet Tube is important to ensure its continued performance and longevity. This includes checking for signs of wear or damage, ensuring that all connections are secure, and cleaning the tube as necessary to remove any buildup that could impede air flow. Common issues with the tube may include leaks or blockages, which can be identified through routine inspections and addressed promptly to prevent engine performance issues.

Performance Enhancements

The Air Inlet Tube plays a role in enhancing engine performance by ensuring that the air entering the engine is clean, cool, and at the right pressure. This can lead to improvements in horsepower, torque, and fuel efficiency, as the engine operates more efficiently with a consistent and optimized air supply. The tube’s design and material contribute to these performance enhancements by providing a reliable and efficient air delivery system.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its high-quality engine components and systems. The company’s history of innovation and commitment to quality is reflected in its products, including the 3686928. Cummins’ reputation for reliability and performance underscores the quality and durability of its components, making them a preferred choice for commercial truck operators and maintenance professionals.

Conclusion

The Cummins 3686928 Air Inlet Tube is a critical component in the efficient operation of commercial truck engines. Its design and construction ensure reliable and efficient air delivery, contributing to enhanced engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.