This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

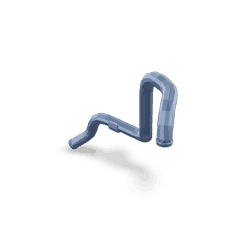

The Cummins 3689158 Air Inlet Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the intake of air into the engine, which is a fundamental requirement for the combustion process. The significance of this part lies in its role in ensuring that the engine receives a consistent and adequate supply of air, which is vital for optimal engine performance and efficiency 4.

Basic Concepts of Air Inlet Tubes

An air inlet tube is a conduit that directs air from the outside environment into the engine’s intake system. Within the engine system, the air inlet tube plays a role in channeling air to the turbocharger or directly to the cylinders, depending on the engine’s design. The tube contributes to the overall performance of the truck by ensuring that the air-fuel mixture is properly balanced, which can affect power output, fuel efficiency, and emissions 1.

Purpose of the Cummins 3689158 Air Inlet Tube

The Cummins 3689158 Air Inlet Tube is specifically engineered to play a role in the truck’s engine system by facilitating the intake of air required for combustion. It is positioned to connect various components of the air intake system, ensuring a smooth and uninterrupted flow of air to the engine. This part is integral to maintaining the engine’s air-fuel ratio, which is necessary for efficient combustion and engine operation 3.

Key Features

The Cummins 3689158 Air Inlet Tube is constructed from durable materials that are resistant to the high temperatures and pressures present in the engine compartment. Its design includes features such as reinforced joints and a smooth interior to minimize air turbulence and maximize airflow efficiency. Additionally, the tube may incorporate unique attributes such as sound-dampening materials to reduce engine noise or a specific shape to enhance performance under certain operating conditions 2.

Benefits

The Cummins 3689158 Air Inlet Tube offers several benefits, including improved engine efficiency due to its optimized airflow design. Its durable construction contributes to the longevity of the component, reducing the need for frequent replacements. Furthermore, by ensuring a consistent air supply, the tube can play a role in enhancing fuel economy and reducing emissions, aligning with regulatory standards and environmental considerations 4.

Installation Process

Installing the Cummins 3689158 Air Inlet Tube requires careful attention to ensure a proper fit and function. The process involves disconnecting the old tube, aligning the new tube with the engine’s intake system, and securing it in place using the appropriate fasteners. Tools such as wrenches and possibly a torque wrench may be required. It is important to follow the manufacturer’s instructions to avoid damage to the tube or the engine system 3.

Maintenance and Care

Regular maintenance of the Cummins 3689158 Air Inlet Tube is necessary to ensure its longevity and optimal performance. This includes periodic cleaning to remove any debris or contaminants that may obstruct airflow, as well as inspection for signs of wear or damage. Proper maintenance can help prevent issues such as reduced engine performance or increased fuel consumption 2.

Troubleshooting Common Issues

Common problems with the Cummins 3689158 Air Inlet Tube may include cracks, leaks, or blockages that can affect engine performance. Troubleshooting steps involve inspecting the tube for visible damage, checking for proper connections, and ensuring that the airflow is not restricted. Solutions may range from cleaning the tube to replacing it if damage is detected 3.

Compatibility and Applications

The Cummins 3689158 Air Inlet Tube is designed for use with specific types of trucks and engine models. Its applications are within the commercial trucking industry, where it is used to enhance the performance and efficiency of heavy-duty engines. Understanding the compatibility of this part with various truck models is important for ensuring proper function and integration within the engine system 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines and components that are known for their reliability, performance, and efficiency in various applications.

Cummins Air Inlet Tube 3689158 Compatibility

The Cummins Air Inlet Tube part number 3689158 is designed to fit seamlessly with several of Cummins’ renowned engine models. This part is crucial for ensuring optimal air flow into the engine, which is essential for maintaining performance and efficiency.

ISX15 CM2350

The ISX15 CM2350 engine is a high-performance model known for its robust power output and reliability. The Air Inlet Tube 3689158 is engineered to integrate perfectly with the ISX15 CM2350, providing a secure and efficient connection that supports the engine’s demanding requirements.

X101

The X101 engine is another model in Cummins’ lineup that benefits from the Air Inlet Tube 3689158. This part ensures that the X101 engine receives the necessary air flow, contributing to its overall performance and longevity. The design of the tube is tailored to fit the specific architecture of the X101 engine, ensuring a snug and reliable fit.

Grouping of Engines

The Air Inlet Tube 3689158 is versatile enough to be used across different engine models, including the ISX15 CM2350 and X101. This compatibility allows for easier inventory management and maintenance, as technicians can use a single part number for multiple engine types. The design and engineering of the tube are consistent across these models, ensuring that it meets the stringent requirements of each engine.

Role of Part 3689158 Air Inlet Tube in Various Components

The Part 3689158 Air Inlet Tube is an essential component in several systems, facilitating the efficient operation of these assemblies. Its primary function is to direct and regulate the flow of air into the system, ensuring optimal performance and reliability.

Air Compressor Kit

In an Air Compressor Kit, the Air Inlet Tube is responsible for channeling ambient air into the compressor. This air is then compressed and stored, ready for various applications such as powering tools or inflating tires. The tube’s design ensures that the air enters the compressor at the correct pressure and velocity, which is vital for the compressor’s efficiency and longevity.

Plumbing Systems

Within Plumbing Systems, the Air Inlet Tube plays a role in aeration components. It allows air to mix with water, which can help reduce water hammer and improve the overall flow dynamics within the pipes. This integration ensures that the plumbing system operates smoothly, minimizing noise and potential damage to the pipes.

Compressor Air Inlet

For the Compressor Air Inlet, the tube is a direct pathway for air to enter the compressor. It is engineered to filter out impurities and regulate the air intake, which is essential for maintaining the compressor’s internal components. This results in a more consistent and reliable air supply, which is critical for the compressor’s performance in industrial and commercial applications.

Conclusion

The Cummins 3689158 Air Inlet Tube is a critical component in the operation of heavy-duty truck engines, ensuring efficient air intake and contributing to overall engine performance and efficiency. Its durable construction, optimized airflow design, and compatibility with various engine models make it a valuable part in the maintenance and operation of commercial trucks.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ ↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ ↩ ↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.