This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

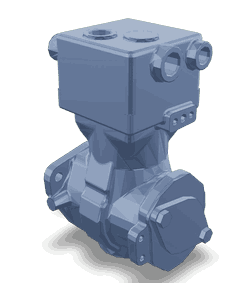

The Cummins 3695160 Air Compressor is a component designed for use in commercial truck operations. Its purpose is to generate and maintain the compressed air necessary for various truck systems, including the braking system, air suspension, and other pneumatic applications. The significance of this air compressor in commercial truck operations lies in its ability to ensure the reliable and efficient functioning of these critical systems.

Basic Concepts of Air Compressors

Air compressors are mechanical devices that convert power into potential energy stored in pressurized air. They operate by drawing in air, compressing it, and storing it in a tank until needed. Air compressors find applications across various industries, but in commercial trucks, they are particularly vital for powering braking systems, air suspension, and other pneumatic controls. The efficient operation of these systems relies on a consistent and reliable supply of compressed air, which the air compressor provides 1.

Role of the Cummins 3695160 Air Compressor in Truck Operations

The Cummins 3695160 Air Compressor plays a significant role in the operation of a truck by supplying the compressed air required for the braking system, air suspension, and other pneumatic systems. In the braking system, compressed air is used to apply the brakes, ensuring safe and effective stopping power. The air suspension system relies on compressed air to adjust the ride height and absorb shocks, contributing to a smoother and more comfortable ride. Additionally, various pneumatic controls and accessories in the truck may also depend on the compressed air supplied by this compressor 2.

Key Features of the Cummins 3695160 Air Compressor

The Cummins 3695160 Air Compressor is characterized by several key features that enhance its performance and reliability. These include high-quality construction materials, efficient compression technology, and durable design elements. The compressor is built to withstand the demanding conditions of commercial truck operations, ensuring long-term reliability and performance. Unique design elements may include advanced cooling systems, noise reduction features, and integrated safety mechanisms to protect against overpressure and other potential issues 3.

Benefits of Using the Cummins 3695160 Air Compressor

Incorporating the Cummins 3695160 Air Compressor into a truck’s system offers several advantages. These include improved reliability due to its robust construction and efficient operation, enhanced performance through consistent and adequate compressed air supply, and potential cost savings over time due to its durability and reduced maintenance requirements. The compressor’s design also contributes to overall system efficiency, which can lead to lower operational costs and increased uptime for the truck 4.

Installation and Integration

Proper installation and integration of the Cummins 3695160 Air Compressor into a truck’s existing system are crucial for optimal performance. Guidelines for installation include ensuring proper alignment, secure mounting, and correct connection to the air lines and electrical systems. Best practices involve following the manufacturer’s instructions carefully, using the appropriate tools and equipment, and conducting thorough testing upon completion to verify proper operation. Common pitfalls to avoid include improper alignment, insufficient securing, and incorrect connections, which can lead to performance issues or system failures.

Maintenance and Troubleshooting

Maintaining the Cummins 3695160 Air Compressor is key to ensuring its longevity and optimal performance. Regular maintenance tasks include checking and replacing air filters, inspecting and tightening connections, and monitoring the compressor’s performance metrics. Troubleshooting techniques for addressing common issues may involve diagnosing unusual noises, investigating drops in air pressure, and addressing leaks in the system. Proactive maintenance and timely troubleshooting can prevent major failures and extend the compressor’s service life.

Performance and Efficiency

The performance metrics and efficiency ratings of the Cummins 3695160 Air Compressor are important considerations for its effectiveness in truck operations. These metrics may include compression ratio, airflow capacity, and energy consumption. Comparing these ratings with other models can provide insight into the compressor’s efficiency and suitability for specific applications. Factors influencing its effectiveness include the quality of installation, regular maintenance, and the overall condition of the truck’s pneumatic systems.

Safety Considerations

When working with the Cummins 3695160 Air Compressor, several safety guidelines and considerations are important. These include proper handling during installation and maintenance, adherence to safety protocols when operating the compressor, and regular inspection for signs of wear or damage. Operational safety measures may involve ensuring the compressor is turned off and depressurized before performing maintenance, using personal protective equipment, and following lockout/tagout procedures to prevent accidental startup during maintenance activities.

Environmental Impact

The environmental impact of using the Cummins 3695160 Air Compressor includes considerations of its energy consumption, emissions, and any eco-friendly features it may possess. Efficient compressors can reduce energy consumption and lower operational costs, while advancements in compressor technology may include features designed to minimize environmental impact, such as reduced noise levels and lower emissions. Assessing the compressor’s environmental footprint involves evaluating these factors and considering the overall benefits of its use in commercial truck operations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a reputable and innovative company in the industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems designed to enhance the performance and efficiency of commercial vehicles. The Cummins 3695160 Air Compressor is part of this extensive product line, reflecting the company’s commitment to quality and innovation in the automotive and heavy-duty truck sectors.

Cummins Air Compressor 3695160 Compatibility

The Cummins Air Compressor part number 3695160 is designed to fit a variety of engines, ensuring reliable performance across multiple applications. This air compressor is engineered to meet the stringent demands of modern engine systems, providing efficient and dependable operation.

ISG11 CM2880 G108 and ISG12 CM2880 G107

The ISG11 CM2880 G108 and ISG12 CM2880 G107 engines are part of a series that benefits from the robust design of the Cummins Air Compressor 3695160. This part is specifically tailored to integrate seamlessly with these engines, enhancing their operational efficiency and reliability.

ISG12 G CMOH6.0 G111

The ISG12 G CMOH6.0 G111 engine is another model that is compatible with the Cummins Air Compressor 3695160. This compatibility ensures that the air compressor can effectively support the engine’s performance, maintaining optimal air pressure and contributing to the overall efficiency of the engine system.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine is designed to work in tandem with the Cummins Air Compressor 3695160. This combination is crucial for maintaining the engine’s performance, ensuring that the air compressor provides the necessary support for the engine’s operational needs.

X11 CM2670 X126B, X12 CM2670 X121B, and X13 CM2670 X122B

The X11 CM2670 X126B, X12 CM2670 X121B, and X13 CM2670 X122B engines are part of a series that benefits from the integration of the Cummins Air Compressor 3695160. This part is engineered to fit these engines, providing the necessary air support to ensure they operate at peak efficiency. The compatibility of this air compressor with these engines is essential for maintaining the performance and reliability of the engine systems.

Role of Part 3695160 Air Compressor in Engine Systems

The integration of the air compressor, specifically part 3695160, within engine systems is fundamental to the efficient operation of several key components. This component is responsible for generating compressed air, which is essential for various functions within the engine.

Fuel Injection System

In modern engines, the air compressor plays a significant role in the fuel injection system. Compressed air is utilized to atomize fuel, ensuring a finer mist is created before it enters the combustion chamber. This enhances fuel efficiency and reduces emissions by promoting a more complete burn.

Turbocharger Support

When paired with a turbocharger, the air compressor aids in increasing the density of the air entering the engine. This allows for more fuel to be burned, thereby boosting power output without significantly increasing engine size. The compressor ensures that the turbocharged system operates smoothly, providing the necessary air pressure to support higher RPMs and performance levels.

Brake System

In vehicles equipped with air brakes, the air compressor is vital. It generates the compressed air required to operate the brake system, ensuring that brakes engage and release efficiently. This is particularly important in heavy-duty vehicles where reliable braking performance is essential for safety.

Suspension System

Some advanced suspension systems use air compressors to adjust ride height and damping characteristics. The compressed air is used to inflate or deflate air springs, allowing for real-time adjustments based on driving conditions. This enhances both comfort and handling, providing a versatile driving experience.

Cabin Comfort

In addition to its mechanical roles, the air compressor also contributes to cabin comfort. It powers the air conditioning system, ensuring that cool air is delivered to the passengers. This involves compressing refrigerant, which then expands and cools, providing a comfortable environment inside the vehicle.

Emission Control

Modern engines are equipped with various emission control systems that rely on compressed air. For instance, the air compressor can supply air for the operation of diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems. These systems help reduce harmful emissions, ensuring the vehicle meets environmental regulations.

Starting System

In some diesel engines, especially those found in heavy-duty applications, compressed air is used to aid in the starting process. The air compressor provides the necessary pressure to turn over the engine, particularly in cold conditions where battery power might be insufficient.

The air compressor, part 3695160, thus serves as a multifaceted component within engine systems, supporting everything from fuel efficiency and performance to safety and comfort. Its reliable operation is essential for the optimal functioning of these interconnected systems.

Conclusion

The Cummins 3695160 Air Compressor is a critical component in commercial truck operations, providing the necessary compressed air for various systems including braking, suspension, and pneumatic controls. Its robust construction, efficient operation, and compatibility with a range of engines make it a reliable choice for ensuring the performance and safety of commercial vehicles. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this compressor.

-

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.