This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3865115 Filler Cap is a component designed for use in commercial trucks. Its primary role is within the vehicle’s fuel system, where it serves to seal the fuel tank. This ensures that fuel is retained within the tank and protected from external contaminants. The filler cap is an integral part of maintaining the efficiency and safety of the truck’s fuel system 1.

Purpose and Function

The Cummins 3865115 Filler Cap functions as a seal for the fuel tank, preventing fuel loss and contamination. When the cap is securely in place, it creates a barrier that keeps fuel from leaking out and stops dirt, water, and other contaminants from entering the fuel tank. This sealing mechanism is vital for maintaining the purity of the fuel, which in turn ensures the engine operates efficiently and reliably 2.

Key Features

The Cummins 3865115 Filler Cap is characterized by its robust design and the materials used in its construction. It is typically made from durable plastics or metals that can withstand the rigors of commercial truck use. The cap features a gasket or sealing ring that ensures a tight fit on the fuel tank, enhancing its ability to prevent leaks. Additionally, the design may include features such as a venting system to allow for the safe release of pressure build-up within the tank 3.

Benefits

The use of the Cummins 3865115 Filler Cap offers several advantages. It contributes to the integrity of the fuel system by ensuring that the fuel tank remains sealed. This leads to improved safety, as the risk of fuel spills is minimized. Furthermore, the cap’s design facilitates ease of use for truck operators, allowing for quick and secure refueling.

Installation and Maintenance

Proper installation of the Cummins 3865115 Filler Cap involves ensuring that it is correctly aligned with the fuel tank opening and securely tightened to achieve a proper seal. Regular maintenance includes inspecting the cap for signs of wear or damage, such as cracks or a deteriorated gasket, and cleaning it to remove any buildup that could affect its sealing ability. These practices help to ensure the longevity and optimal performance of the filler cap.

Troubleshooting Common Issues

Common issues with filler caps can include leaks or difficulty in opening the cap. If a leak is detected, it may be necessary to replace the gasket or the entire cap if it is damaged. Difficulty in opening the cap could be due to pressure build-up within the tank, which may require the venting system to be checked and cleared if necessary.

Safety Considerations

When handling and maintaining the Cummins 3865115 Filler Cap, it is important to follow safety practices to avoid fuel spills and ensure a secure seal on the fuel tank. This includes wearing appropriate personal protective equipment and ensuring that the area is well-ventilated to dissipate any fuel fumes.

Environmental Impact

The proper functioning of the Cummins 3865115 Filler Cap plays a role in reducing fuel spills and emissions. By maintaining a secure seal on the fuel tank, it helps to prevent fuel from escaping into the environment, which can contribute to pollution. Additionally, by keeping the fuel clean and free from contaminants, the cap supports more efficient engine operation, which can lead to lower emissions.

Cummins Overview

Cummins Inc. is a company with a long-standing history in the manufacturing of diesel engines. Known for its expertise and commitment to innovation, Cummins has established itself as a leader in the automotive industry. The company’s products, including the Cummins 3865115 Filler Cap, are designed with a focus on quality and performance, reflecting Cummins’ dedication to providing reliable solutions for commercial vehicle operators.

Cummins Engine Part 3865115: Filler Cap Compatibility

The Cummins part number 3865115, identified as a Filler Cap, is a critical component in the maintenance and operation of various Cummins engines. This part is designed to ensure the proper sealing and accessibility of the engine’s fuel or coolant systems, depending on its specific application within the engine architecture.

N14 Celect Plus Engine

The N14 Celect Plus engine is a robust and reliable power unit, often utilized in heavy-duty applications such as construction equipment, mining machinery, and industrial power systems. The Filler Cap part number 3865115 is integral to the N14 Celect Plus engine’s operation, ensuring that the fuel system remains sealed and free from contaminants. This cap is typically located on the top of the fuel tank or the fuel system’s access point, providing a secure and easy-to-use interface for refueling and maintenance.

Grouping of Engines

While the N14 Celect Plus is a notable example, the Filler Cap part number 3865115 is also compatible with other Cummins engines within the same family or similar configurations. This part’s design and functionality are consistent across various models, ensuring a seamless fit and reliable performance. The compatibility of this filler cap extends to engines that share similar design principles and maintenance requirements, making it a versatile component in the Cummins engine lineup.

The Filler Cap part number 3865115 is engineered to meet the stringent demands of heavy-duty applications, providing durability and ease of use. Its design ensures a tight seal, preventing leaks and maintaining the integrity of the engine’s fuel system. This part is a testament to Cummins’ commitment to quality and reliability, offering operators and maintenance personnel a dependable solution for their engine needs.

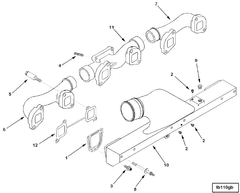

Part 3865115 Filler Cap Component Usage

The part 3865115 Filler Cap is an essential component in various engine systems, ensuring the secure and efficient operation of fuel and fluid systems.

In the context of an arrangement involving multiple fuel tanks or reservoirs, the Filler Cap plays a significant role in maintaining the integrity of the fuel system. It allows for the safe and controlled addition of fuel while preventing contaminants from entering the system. This is particularly important in high-performance engines where fuel purity directly impacts engine efficiency and performance.

When integrated with a turbocharger system, the Filler Cap ensures that the lubrication system remains uncontaminated. Turbochargers require precise lubrication to operate efficiently, and the Filler Cap facilitates the addition of the correct lubricants without the risk of introducing impurities. This is vital for the longevity and performance of the turbocharger, as any contamination can lead to increased wear and potential failure.

Overall, the Filler Cap is a fundamental component that supports the reliable operation of engine systems by ensuring that fluids are added securely and contaminants are kept out.

Conclusion

The Cummins 3865115 Filler Cap is a vital component in the fuel systems of commercial trucks and various Cummins engines. Its robust design, ease of use, and compatibility with multiple engine models make it a reliable choice for maintaining the integrity of fuel and lubrication systems. Proper installation, regular maintenance, and adherence to safety practices are essential for ensuring the optimal performance and longevity of this part.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.