This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

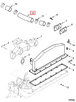

The Cummins 3908776 Air Tube is a component designed for use in commercial trucks, playing a significant role in the vehicle’s air system. Its purpose is to facilitate the efficient operation of the truck by managing the flow of air within the system. Understanding its function and significance is key to maintaining the overall performance and safety of commercial trucks 1.

Basic Concepts of Air Tubes

An air tube serves as a conduit for air within a truck’s air system. Its general function is to transport compressed air from the compressor to various components that require it, such as the brakes, suspension, and other pneumatic systems. The air tube contributes to the vehicle’s performance and safety by ensuring that these components receive a consistent and reliable air supply 2.

Purpose of the Cummins 3908776 Air Tube

This Cummins part is specifically designed to direct and regulate the flow of air within the truck’s air system. It plays a role in maintaining the pressure and distribution of air to ensure that all pneumatic components function correctly. By managing air flow, it helps in the efficient operation of the truck’s braking system, suspension, and other air-dependent features.

Key Features

The 3908776 is characterized by several key features that enhance its performance. It is constructed from durable materials to withstand the pressures and conditions within the truck’s air system. Its design includes elements that ensure a secure connection to other components, minimizing the risk of leaks. Additionally, it may feature unique characteristics such as reinforced sections or specialized coatings to improve durability and efficiency.

Benefits

The advantages provided by this part include improved efficiency within the air system, enhanced durability under pressure, and reliable performance over time. These benefits contribute to the overall effectiveness of the truck’s pneumatic systems, ensuring that they operate smoothly and consistently.

Installation and Integration

Installing the 3908776 involves connecting it to the appropriate points within the truck’s air system. Specific considerations may include ensuring proper alignment and securing connections to prevent leaks. Integration requires attention to detail to maintain the integrity of the air system and ensure that the tube functions as intended.

Maintenance and Care

To ensure optimal performance, regular maintenance of the 3908776 is recommended. This includes inspecting the tube for signs of wear or damage, cleaning it to remove any debris that could obstruct air flow, and checking connections for tightness. Proper care helps in prolonging the tube’s lifespan and maintaining the efficiency of the air system.

Troubleshooting Common Issues

Common problems associated with air tubes can include leaks, blockages, or damage to the tube itself. Troubleshooting these issues involves identifying the source of the problem, whether it’s a loose connection, a crack in the tube, or an obstruction within the tube. Step-by-step methods for resolving these issues may include tightening connections, replacing damaged sections, or clearing blockages.

Compatibility and Applications

The 3908776 is designed for use in specific types of trucks and air systems. Its applications include various commercial truck models where it plays a role in the efficient operation of the vehicle’s pneumatic systems. Understanding its compatibility ensures that it is used in the correct context, maximizing its effectiveness.

Safety Considerations

When working with the 3908776, safety protocols should be followed to protect both the technician and the vehicle. This includes handling the tube with care to avoid damage, ensuring that installations are performed correctly to prevent accidents, and maintaining the tube according to recommended practices to ensure ongoing safety and reliability.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a history of developing reliable and efficient components for trucks, Cummins has built a reputation for excellence. Its products, including the 3908776, reflect this dedication to providing high-quality solutions for the commercial trucking sector 3.

Cummins Air Tube Part 3908776 Compatibility

The Cummins Air Tube part number 3908776 is designed to fit seamlessly with several engine models, ensuring optimal air flow and performance. This part is engineered to meet the specific needs of the following engines:

- 4B3.9

- 6B5.9

These engines, while differing in their configurations and capacities, share a commonality in their requirement for efficient air management. The air tube part 3908776 is crafted to integrate smoothly with these engines, providing a reliable connection that supports the engine’s operational demands.

For the 4B3.9 engine, the air tube ensures that the air intake system functions efficiently, contributing to the engine’s overall performance and longevity. Similarly, for the 6B5.9 engine, this part plays a role in maintaining the air flow necessary for optimal combustion and power output.

By fitting these engines, the air tube part 3908776 underscores Cummins’ commitment to providing high-quality, durable components that enhance engine performance and reliability.

Role of Part 3908776 Air Tube in Engine Systems

The part 3908776 Air Tube is a component in the air management system of various engine setups. Its primary function is to facilitate the efficient transfer of air between different parts of the engine, ensuring optimal performance and reliability.

Airflow Management in Turbocharger Systems

In turbocharged engines, the 3908776 Air Tube plays a role in managing the airflow from the turbocharger to the engine’s intake manifold. This tube ensures that the compressed air from the turbocharger is delivered smoothly and without leaks, which is vital for maintaining the turbocharger’s efficiency and the engine’s overall performance. The precise arrangement of this tube in relation to the turbocharger location is designed to minimize turbulence and maximize airflow, contributing to better engine response and power output.

Integration with Engine Arrangement

The placement and routing of the 3908776 Air Tube are carefully considered in the engine’s overall arrangement. It must be positioned to avoid interference with other components while ensuring a direct and unobstructed path for the air. This careful integration helps in reducing the risk of air leaks, which can lead to a loss of power and efficiency. Additionally, the tube’s design often includes features to withstand the high pressures and temperatures associated with turbocharged systems, further enhancing its reliability.

Turbocharger Location Considerations

The location of the turbocharger in the engine bay directly influences the routing and design of the 3908776 Air Tube. Whether the turbocharger is mounted on the exhaust side or integrated into the engine’s air intake system, the tube must be configured to accommodate these variations. This adaptability ensures that the air tube can effectively serve its purpose across different engine designs and configurations, maintaining consistent performance and efficiency.

Conclusion

The Cummins 3908776 Air Tube is a critical component in the air management system of commercial trucks, designed to ensure efficient air flow and system reliability. Its compatibility with specific engine models, such as the 4B3.9 and 6B5.9, highlights its importance in maintaining engine performance and longevity. Regular maintenance and proper installation are essential to maximize its benefits and ensure the safety and efficiency of the vehicle’s air system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.