This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Air Transfer Tube (Part #5274663) is a component designed to facilitate the efficient transfer of air within the air systems of commercial trucks. Its purpose is to ensure that air is distributed effectively throughout the truck’s air brake system and other pneumatic components. The significance of this part lies in its contribution to the overall performance and safety of the vehicle, particularly in maintaining the integrity and responsiveness of the braking system.

Basic Concepts and Functionality

The Air Transfer Tube operates on the fundamental principle of directing pressurized air from the compressor to various components within the truck’s air system. It plays a role in maintaining efficient airflow by ensuring that air reaches its intended destinations without significant loss of pressure or efficiency. This component is integral to the system’s ability to perform its functions reliably under varying conditions 1.

Purpose and Role in Truck Operation

In the operation of a commercial truck, the Air Transfer Tube serves several specific functions. It contributes to the air brake system by ensuring that brakes receive adequate air pressure for optimal performance. Additionally, it supports other pneumatic components by providing a consistent and reliable air supply. This part is instrumental in maintaining the truck’s operational efficiency and safety, particularly in scenarios where quick and reliable braking is crucial 2.

Key Features

The Air Transfer Tube is characterized by several primary features that enhance its performance and durability. It is constructed from materials that are resistant to the high pressures and temperatures encountered within a truck’s air system. The design of the tube includes features that ensure a secure fit within the system, minimizing the risk of leaks or disconnections. These attributes contribute to the tube’s ability to withstand the demands of commercial truck operation 3.

Benefits

The advantages provided by the Air Transfer Tube include improved efficiency within the air system, leading to more reliable operation of pneumatic components. Its design and construction contribute to the overall reliability of the truck’s air brake system, potentially leading to cost savings for fleet operators through reduced maintenance needs and improved vehicle uptime 4.

Installation and Integration

Proper installation of the Air Transfer Tube within a truck’s air system involves ensuring compatibility with other components and making any necessary modifications to achieve a secure and efficient connection. Guidelines for installation emphasize the importance of following manufacturer recommendations to ensure the tube functions as intended within the system.

Troubleshooting and Maintenance

Common issues that may arise with the Air Transfer Tube include leaks, blockages, or damage due to wear and tear. Diagnostic procedures for identifying these issues involve checking for signs of air loss or inconsistent performance within the air system. Recommended maintenance practices include regular inspection for signs of wear, ensuring connections are secure, and replacing the tube if significant damage is detected. These practices help ensure the tube continues to perform optimally and contributes to the safety and efficiency of the truck’s operation.

Safety Considerations

Handling, installing, and maintaining the Air Transfer Tube require adherence to safety precautions to prevent accidents and ensure the well-being of truck operators and maintenance personnel. These precautions include working in a well-ventilated area, using appropriate personal protective equipment, and following all manufacturer guidelines for installation and maintenance. Attention to these safety considerations helps prevent injuries and ensures the component functions safely within the truck’s air system.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to producing high-quality automotive components. With a history of innovation and excellence, Cummins has established a reputation for reliability and performance in the components it produces. The company’s dedication to quality is evident in its range of products, including the Air Transfer Tube, which is designed to meet the demanding requirements of commercial truck operations.

Cummins Air Transfer Tube 5274663 Compatibility

The Cummins Air Transfer Tube, part number 5274663, is a critical component designed to ensure the efficient transfer of air within the engine system. This part is specifically engineered to fit seamlessly with various Cummins engines, enhancing their performance and reliability.

QSB6.7 CM2250

The QSB6.7 CM2250 engine is one of the models that benefit from the integration of the Air Transfer Tube 5274663. This part plays a pivotal role in maintaining the optimal air flow necessary for the engine’s combustion process, ensuring that the engine operates at peak efficiency.

Group Compatibility

The Air Transfer Tube 5274663 is not limited to a single engine model but is compatible with a range of Cummins engines. Its design ensures a precise fit and function across different engine types, making it a versatile component for various applications. This compatibility extends to other models within the Cummins engine family, providing a reliable solution for maintaining air transfer efficiency.

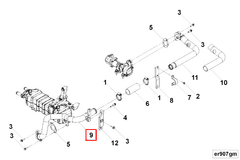

Understanding the Role of Part 5274663 Air Transfer Tube in Engine Systems

The Air Transfer Tube 5274663 is an essential component in the exhaust recirculation air plumbing of various engine systems. This tube facilitates the movement of exhaust gases from the exhaust manifold to the intake manifold, playing a significant role in reducing nitrogen oxides (NOx) emissions.

In the context of exhaust recirculation (EGR) systems, the Air Transfer Tube connects to the EGR valve, allowing a measured flow of exhaust gases to be reintroduced into the intake air stream. This process lowers the combustion temperature in the cylinders, which in turn reduces the formation of NOx.

The tube interfaces with several other components to ensure efficient operation. It connects to the EGR cooler, where the recirculated exhaust gases are cooled before entering the intake manifold. This cooling process is vital for maintaining optimal engine performance and preventing damage to the intake system due to high temperatures.

Additionally, the Air Transfer Tube works in conjunction with the EGR pressure feedback sensor, which monitors the pressure within the EGR system. This sensor provides data to the engine control unit (ECU), allowing it to adjust the EGR valve operation for precise control of exhaust gas flow.

The tube also connects to the intake manifold, where the cooled exhaust gases mix with the fresh air-fuel mixture. This mixture is then drawn into the cylinders during the intake stroke, completing the EGR process.

Overall, the Air Transfer Tube 5274663 is integral to the functioning of the EGR system, ensuring that exhaust gases are effectively managed to meet emission standards while maintaining engine efficiency.

Conclusion

The Cummins Air Transfer Tube (Part #5274663) plays a critical role in the efficient operation of commercial truck air systems and engine performance. Its design and functionality contribute to the reliability and safety of the vehicle, ensuring optimal air distribution and emission control. Proper installation, maintenance, and adherence to safety precautions are essential for maximizing the benefits of this component.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022.

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010.

↩ -

Diesel Engines, A. J. Wharton, Butterworth-Heinemann Ltd, 1991.

↩ -

Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.