This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5292242 Air-Fuel Throttle Valve is engineered to regulate the air-fuel mixture in diesel engines, specifically for heavy-duty truck applications. This part ensures optimal engine performance by maintaining the correct balance of air and fuel, which is essential for efficient operation, impacting both engine performance and fuel efficiency 1.

Basic Concepts of Air-Fuel Throttle Valves

Air-fuel throttle valves operate by regulating the mixture of air and fuel that enters the engine’s combustion chamber. In diesel engines, precise control of this mixture is vital for efficient combustion, directly affecting engine power, fuel consumption, and emissions. The valve adjusts the amount of air allowed into the engine, which in turn affects the fuel delivery required for combustion 2.

Operation of the Cummins 5292242 Air-Fuel Throttle Valve

The Cummins 5292242 Air-Fuel Throttle Valve modulates the airflow into the engine in response to various operating conditions. It interacts with the engine’s electronic control unit (ECU) to adjust the throttle position based on inputs such as engine load, speed, and temperature. This dynamic adjustment ensures that the engine operates within its optimal performance range under varying conditions 3.

Role in Truck Operation

In heavy-duty truck operation, the Cummins 5292242 Air-Fuel Throttle Valve ensures that the engine receives the correct air-fuel mixture for combustion. This contributes to engine performance by optimizing power output and fuel efficiency. Additionally, it helps in reducing emissions by ensuring that combustion is as complete as possible, minimizing the release of unburned fuel and other pollutants.

Key Features

The Cummins 5292242 Air-Fuel Throttle Valve is characterized by its robust design and the use of high-quality materials, which enhance its durability and performance. Its design allows for precise control of the air-fuel mixture, and it is engineered to withstand the harsh operating conditions typical of heavy-duty truck environments. Advanced sealing technologies are employed to prevent leaks and ensure efficient operation.

Benefits

The advantages of the Cummins 5292242 Air-Fuel Throttle Valve include improved engine efficiency, leading to better fuel economy. It also contributes to reduced emissions, aligning with environmental regulations. Enhanced drivability is another benefit, as the valve helps maintain smooth engine operation across a wide range of driving conditions.

Installation Process

Installing the Cummins 5292242 Air-Fuel Throttle Valve requires careful attention to ensure proper fitment and function. The process involves disconnecting the old valve, cleaning the mounting area, and securely attaching the new valve. It’s important to follow manufacturer guidelines to avoid damage and ensure optimal performance.

Maintenance Tips

To ensure the Cummins 5292242 Air-Fuel Throttle Valve operates efficiently over time, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could affect performance, and ensuring all connections are secure. Adhering to these maintenance practices can help prolong the valve’s lifespan and maintain engine efficiency.

Troubleshooting Common Issues

Common issues with the Cummins 5292242 Air-Fuel Throttle Valve may include erratic engine performance or difficulty starting the engine. These problems can often be traced back to issues with the valve’s operation or its electronic connections. Troubleshooting steps may involve checking for proper valve operation, inspecting electrical connections, and ensuring the valve is clean and free from obstructions.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product offerings cater to various sectors, including heavy-duty trucking, where reliability and performance are paramount.

Compatibility

The Cummins Air-Fuel Throttle Valve part number 5292242 is designed to regulate the airflow into the engine, ensuring optimal performance and efficiency. It is compatible with several engine models, including ISB (Chrysler) Engines and other Cummins engine models, providing precise control over the air-fuel mixture 4.

Installation and Functionality

When installing the Cummins 5292242 Air-Fuel Throttle Valve, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. This part interfaces with the engine’s electronic control unit (ECU) to manage airflow dynamically, adapting to varying engine loads and conditions. This ensures that the engine maintains optimal performance across different operating scenarios.

Role in Engine Systems

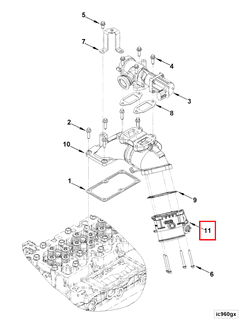

The Cummins 5292242 Air-Fuel Throttle Valve is an integral component in the orchestration of air and fuel delivery within an engine system. It works in concert with the air intake connection to regulate the precise mixture of air and fuel entering the combustion chamber.

When actuated, the throttle valve modulates the airflow through the air intake connection. This modulation is essential for maintaining the desired air-fuel ratio, which is pivotal for optimal engine performance and efficiency. The valve responds to signals from the engine control unit (ECU), adjusting the throttle opening to meet the engine’s demand for power under varying conditions.

In addition to its primary function, the throttle valve also interacts with other components such as the mass airflow (MAF) sensor and the oxygen (O2) sensor. The MAF sensor measures the amount of air entering the engine, providing data to the ECU to calculate the appropriate fuel delivery. The O2 sensor monitors the exhaust gases, offering feedback to the ECU to fine-tune the air-fuel mixture for emissions compliance and performance.

The throttle valve’s role extends to enhancing drivability by ensuring smooth acceleration and deceleration. It contributes to the engine’s responsiveness by quickly adjusting the air intake in response to driver input, thus facilitating a seamless driving experience.

Furthermore, the integration of the throttle valve with the electronic throttle control (ETC) system allows for precise control over the throttle position, improving fuel economy and reducing emissions. The ETC system uses sensors and actuators to manage the throttle valve, ensuring that it operates within the parameters set by the ECU for the best possible engine performance.

Conclusion

The Cummins 5292242 Air-Fuel Throttle Valve plays a significant role in the efficient operation of diesel engines in heavy-duty trucks. By ensuring the correct air-fuel mixture, this part contributes to optimal engine performance, fuel efficiency, and reduced emissions. Regular maintenance and proper installation are crucial for its effective operation, highlighting the importance of adhering to manufacturer guidelines and performing routine checks to ensure longevity and performance.

-

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan and Avinash Kumar, Springer Nature, 2020

↩ -

Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, Robert Bosch GmbH, 2014

↩ -

QSK38 CM2350 K125, Bulletin Number 5613390, Operation and Maintenance Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.