This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

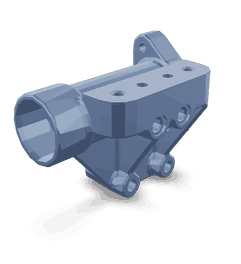

The Cummins 5297750 Air Transfer Tube is a component designed to facilitate the efficient transfer of air within the air systems of commercial trucks. Its role is significant in ensuring the proper operation of various air-dependent systems, particularly the air brake system, which is vital for the safety and performance of heavy-duty vehicles.

Basic Concepts of Air Transfer Tubes

An Air Transfer Tube is a conduit that allows pressurized air to move from one part of a truck’s air system to another. It plays a role in maintaining consistent air pressure and efficient airflow, which are necessary for the operation of air brakes, suspension systems, and other pneumatic components. The tube ensures that air is distributed evenly and reaches all necessary parts of the system without significant loss of pressure 1.

Purpose of the 5297750 Air Transfer Tube

The 5297750 Air Transfer Tube is specifically designed to enhance the functionality of a truck’s air brake system. It facilitates the transfer of compressed air from the air compressor to the brake chambers and other air-actuated components. This ensures that the brakes engage and release efficiently, contributing to the overall safety and performance of the vehicle. Additionally, it supports other air-dependent systems by ensuring a steady supply of pressurized air 2.

Key Features

This Cummins part is constructed from durable materials that can withstand the high pressures and temperatures typical of a truck’s air system. Its design includes features such as reinforced joints and a smooth interior to minimize air resistance and ensure efficient airflow. The tube is also designed to be compatible with a variety of truck models, providing a versatile solution for fleet operators.

Benefits

The use of the 5297750 Air Transfer Tube can lead to improved airflow efficiency within the truck’s air system. This can result in more responsive brakes and reduced wear on air-dependent components. The tube’s durable construction contributes to its longevity, potentially offering cost savings for fleet operators by reducing the frequency of replacements. Additionally, efficient airflow can contribute to better overall performance and safety of the vehicle 3.

Installation Process

Installing the 5297750 Air Transfer Tube requires careful attention to ensure a proper fit and function within the truck’s air system. The process involves disconnecting the old tube, if present, and connecting the new tube to the appropriate fittings. Tools such as wrenches and possibly a torque wrench may be required. It is important to follow the manufacturer’s instructions to ensure that the tube is installed correctly and securely.

Troubleshooting Common Issues

Common issues with Air Transfer Tubes can include leaks or blockages, which can affect the performance of the air system. Troubleshooting steps may involve inspecting the tube for visible damage, checking connections for tightness, and testing for leaks using appropriate methods. Addressing these issues promptly can help maintain the efficiency and safety of the truck’s air system.

Maintenance Tips

Regular maintenance of the 5297750 Air Transfer Tube is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the tube to remove any debris that may obstruct airflow, and ensuring that all connections are tight and secure. Following a maintenance schedule can help prevent issues and ensure the continued efficient operation of the truck’s air system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is well-regarded in the commercial truck industry for its quality and reliability. The company’s commitment to excellence is reflected in its products, including the 5297750 Air Transfer Tube.

Role of Part 5297750 Air Transfer Tube in Engine Systems

The 5297750 Air Transfer Tube is an integral component in the efficient operation of various engine systems. Its primary function is to facilitate the movement of air between different parts of the engine, ensuring optimal performance and emissions control.

Air Transfer Tube in Plumbing Systems

In the context of engine plumbing systems, the Air Transfer Tube plays a significant role in managing the flow of air to and from critical components. It connects the air intake system to the combustion chambers, ensuring a steady supply of air required for the fuel combustion process. This steady airflow is essential for maintaining the correct air-fuel ratio, which is vital for efficient combustion and power output.

Integration with Exhaust Recirculation Air (ERA) Systems

The Air Transfer Tube is also a key component in Exhaust Recirculation Air (ERA) systems. ERA systems are designed to reduce nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gas back into the intake manifold. The Air Transfer Tube in this system ensures that the recirculated exhaust gases are properly mixed with the incoming air, promoting a more complete combustion process and reducing harmful emissions.

This component helps in maintaining the efficiency of the ERA system by providing a dedicated pathway for the recirculated gases, preventing any potential leaks or inefficiencies that could arise from using generic plumbing.

Enhanced Engine Performance and Emissions Control

By ensuring a consistent and controlled flow of air, the Air Transfer Tube contributes to enhanced engine performance and better emissions control. Its precise role in both the air intake and ERA systems underscores its importance in modern engine designs, where efficiency and environmental compliance are paramount.

Conclusion

In summary, the 5297750 Air Transfer Tube is a vital link in the chain of components that work together to ensure the engine operates smoothly, efficiently, and within regulatory emissions standards.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.