5307202

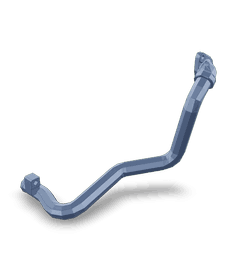

Air Transfer Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5307202 Air Transfer Tube is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s air system, contributing to the overall performance and efficiency of the truck. Understanding its purpose and significance is key to maintaining the vehicle’s operational integrity.

Basic Concepts of Air Transfer Tubes

An Air Transfer Tube is a conduit that facilitates the movement of compressed air within a truck’s air system. This system is vital for various functions, including the operation of air brakes and other air-dependent subsystems. The efficiency of air transfer directly impacts the responsiveness and safety of the braking system, as well as the performance of other air-operated components 1.

Purpose of the Cummins 5307202 Air Transfer Tube

This Cummins part plays a role in the truck’s air brake system by ensuring a consistent and reliable supply of compressed air to the brakes and other subsystems. Its function is to transfer air efficiently, which is crucial for the timely and effective operation of the air brakes, as well as for maintaining the pressure required for other air-dependent systems within the truck.

Key Features

The 5307202 is characterized by several features that enhance its performance and durability. These include its material composition, which is designed to withstand the pressures and temperatures within the air system, and its design elements that ensure a secure fit and efficient air transfer. Unique attributes may also include corrosion-resistant coatings or reinforced sections to handle high-stress areas.

Benefits of Using the Cummins 5307202 Air Transfer Tube

Utilizing this part offers several advantages. These include improved air flow efficiency, which can lead to better performance of air-dependent systems, increased durability under various operating conditions, and enhanced reliability, reducing the likelihood of system failures due to air transfer issues.

Installation and Integration

Proper installation of the 5307202 is important for its effective function within the truck’s air system. Guidelines for installation include ensuring compatibility with the specific truck model and integrating the tube within the existing air system to maintain system integrity and performance. Attention to detail during installation can prevent future issues and ensure optimal operation.

Troubleshooting Common Issues

Common problems associated with Air Transfer Tubes can include leaks, blockages, or damage to the tube itself. Potential causes may range from manufacturing defects to wear and tear over time. Recommended troubleshooting steps involve inspecting the tube for visible damage, checking for leaks in the system, and ensuring that the tube is properly installed and secured.

Maintenance Tips

Routine maintenance practices are important for ensuring the longevity and optimal performance of the 5307202. This includes regular inspection intervals to check for signs of wear or damage, and cleaning procedures to remove any debris that could obstruct air flow. Adhering to these maintenance tips can help prevent issues and ensure the tube continues to function effectively.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s commitment to advancing technology and improving efficiency is evident in its wide range of products, including the 5307202, designed to meet the demanding requirements of commercial truck operations.

Understanding the Role of 5307202 in Engine Systems

The 5307202 is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the movement of air between different parts of the engine, ensuring optimal performance and emissions control.

Integration with Plumbing Systems

In engine systems, the Air Transfer Tube is often integrated with the plumbing network. This network includes a series of pipes and hoses designed to manage the flow of fluids and gases. The Air Transfer Tube plays a significant role in this system by directing air to where it is needed most, whether it be for combustion processes or cooling mechanisms. This ensures that the engine maintains a balanced air-fuel mixture, which is vital for efficient combustion and reduced emissions 2.

Role in Exhaust Recirculation Air Systems

The Air Transfer Tube is also a key component in Exhaust Recirculation (EGR) systems. EGR systems are designed to reduce nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gas back into the intake manifold. The Air Transfer Tube facilitates this process by transporting the recirculated exhaust gases from the exhaust manifold to the intake system. This not only helps in lowering emissions but also improves fuel efficiency by allowing the engine to operate at lower temperatures.

Enhancing Engine Performance

By ensuring a consistent and controlled flow of air, the Air Transfer Tube contributes to the overall performance of the engine. It helps in maintaining the correct air-fuel ratio, which is essential for smooth operation and power delivery. Additionally, the tube’s role in the EGR system ensures that the engine operates within safe temperature limits, prolonging the lifespan of engine components.

Supporting Emissions Control

In modern engine systems, emissions control is a top priority. The Air Transfer Tube supports this by enabling efficient air management, which is crucial for the proper functioning of catalytic converters and other emissions control devices. By ensuring that the right amount of air is available at the right time, the tube helps in reducing harmful emissions and complying with environmental regulations.

Conclusion

The 5307202 is a vital component in the intricate network of engine systems. Its role in air management, integration with plumbing systems, and support for exhaust recirculation makes it indispensable for both performance and emissions control. Understanding its function and importance can lead to better maintenance practices and improved engine efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.