This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

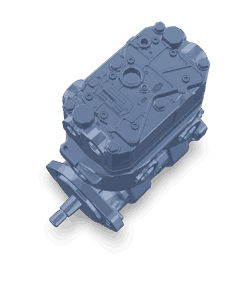

The Cummins 5339232 Air Compressor is a component designed for use in commercial trucks. It serves to generate and maintain the compressed air necessary for various truck systems. Its role is significant in ensuring the efficient operation of pneumatic systems within commercial vehicles.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. By compressing air, the compressor increases its pressure, which can then be used to perform work. In commercial trucks, air compressors are integral to systems such as braking, suspension, and other pneumatic controls. They work by drawing in air, compressing it, and storing it in tanks until needed 1.

Purpose of the Cummins 5339232 Air Compressor

This Cummins part is specifically designed to provide the necessary compressed air for a truck’s braking system, suspension, and other pneumatic systems. It ensures that these systems have a reliable source of pressurized air, which is crucial for their operation. The compressor plays a role in maintaining the air pressure required for safe and effective braking, as well as for supporting the truck’s suspension system under load 2.

Key Features

This part is characterized by several key features. Its design is robust, built to withstand the demanding conditions of commercial truck operations. The compressor incorporates advanced technology to enhance its efficiency and reliability. It is constructed with high-quality materials to ensure durability and long-term performance. Additionally, the compressor is engineered to operate quietly, reducing noise pollution and improving the driving experience.

Benefits

Utilizing this Cummins part in truck operations offers several advantages. It contributes to improved efficiency by providing a consistent supply of compressed air, which is vital for the optimal functioning of pneumatic systems. The compressor’s reliable performance ensures that trucks can operate safely and effectively, even under challenging conditions. Furthermore, its advanced design and build quality contribute to enhanced durability and reduced maintenance requirements.

Installation Process

Installing this part involves several steps. It is important to ensure that the truck’s engine is turned off and cooled down before beginning the installation. The necessary tools and any required adapters should be prepared beforehand. The installation process includes mounting the compressor to the engine, connecting it to the air lines, and securing all connections. It is crucial to follow the manufacturer’s instructions carefully to ensure a proper and safe installation.

Maintenance Tips

To ensure the longevity and optimal performance of this part, regular maintenance is recommended. This includes checking for leaks in the air lines and connections, ensuring that the compressor is securely mounted, and monitoring the compressor’s performance for any signs of wear or malfunction. Regular servicing, as per the manufacturer’s guidelines, will help maintain the compressor’s efficiency and reliability.

Troubleshooting Common Issues

Common issues with this part may include leaks, unusual noises, and performance problems. Identifying the source of leaks is crucial for maintaining the compressor’s efficiency. Unusual noises may indicate loose components or worn parts that require attention. Performance issues can often be traced back to inadequate maintenance or improper installation. Addressing these issues promptly can help prevent more significant problems down the line.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and performance. The company’s products are designed to meet the demanding requirements of commercial vehicle operations, providing reliable and efficient solutions for a wide range of applications.

Cummins Air Compressor Part 5339232 Compatibility

The Cummins Air Compressor part number 5339232 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to work with the following engines:

- B4.5 CM2350 B129B

- F4.5 CM2620 F139B

- ISB4.5 CM2350 B104

These engines, while distinct in their specifications and applications, share common design elements that allow the 5339232 air compressor to integrate effectively. The compatibility of this air compressor with these engines ensures that users can maintain consistent performance and reliability across different engine models.

For the B4.5 CM2350 B129B and ISB4.5 CM2350 B104, the air compressor part 5339232 is engineered to fit the specific mounting points and airflow requirements of these engines. This ensures that the air compressor can efficiently manage the air supply needed for optimal engine operation.

Similarly, the F4.5 CM2620 F139B engine is designed to work with the 5339232 air compressor, providing a reliable air supply that meets the engine’s demands. The design of the air compressor ensures that it can handle the unique airflow and pressure requirements of the F4.5 CM2620 F139B engine, contributing to its overall performance and longevity.

By ensuring compatibility with these engines, the Cummins Air Compressor part 5339232 provides a reliable and efficient solution for maintaining the air supply needs of these engines, enhancing their operational efficiency and reliability.

Role of Part 5339232 Air Compressor in Engine Systems

The part 5339232 Air Compressor is an integral component in various engine systems, facilitating efficient operation and performance. It works in conjunction with several key components to ensure optimal engine functionality.

Interaction with the Compressor

The Air Compressor, designated as part 5339232, is designed to increase the pressure of the air entering the engine. This pressurized air is essential for the combustion process, as it allows for a more complete burn of the fuel-air mixture. The compressor draws in ambient air and compresses it before it is delivered to the engine’s intake manifold.

Enhancing Airflow

By compressing the air, the Air Compressor ensures that a greater mass of air is available for combustion. This increased airflow supports higher engine performance, allowing for more power output and improved efficiency. The compressed air mixes with the fuel in the combustion chamber, leading to a more robust and controlled explosion that drives the engine’s pistons.

Support for Turbocharging and Supercharging

In turbocharged and supercharged engine systems, the Air Compressor plays a significant role. It works alongside the turbocharger or supercharger to provide additional pressurized air. This synergy enhances the engine’s ability to produce power at higher RPMs, making the Air Compressor a vital component in high-performance engine setups.

Contribution to Fuel Efficiency

Efficient air compression directly impacts fuel efficiency. By ensuring that the air-fuel mixture is optimal, the Air Compressor helps the engine operate more cleanly and efficiently. This results in better fuel economy and reduced emissions, making it a valuable component in modern engine designs focused on sustainability.

Integration with Engine Control Systems

Modern engines are equipped with sophisticated control systems that monitor and adjust various parameters, including air pressure. The Air Compressor part 5339232 is often integrated with these systems to maintain precise control over air delivery. This integration ensures that the engine receives the exact amount of compressed air needed for optimal performance under varying conditions.

Conclusion

In summary, the part 5339232 Air Compressor is a fundamental component that enhances engine performance, efficiency, and overall functionality by ensuring a consistent supply of pressurized air for combustion. Its robust design, advanced technology, and compatibility with various engine models make it a reliable and efficient solution for commercial truck operations 3.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.