This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

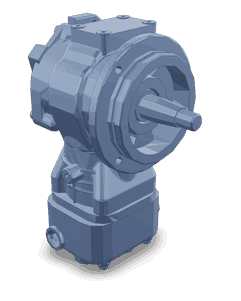

The Cummins 5398515 Air Compressor is a component designed for use in commercial trucks. It serves a vital role in generating compressed air, which is necessary for various truck systems. Its significance lies in enhancing the efficiency and reliability of truck operations, contributing to safer and more effective commercial transportation 1.

Basic Concepts of Air Compressors

Air compressors are mechanical devices that convert power into potential energy stored in pressurized air. They operate by drawing in air, compressing it, and storing it in a tank until needed. In various industries, including commercial trucking, air compressors are used to power tools, operate machinery, and support vehicle systems. In the context of commercial trucks, air compressors are integral to the functioning of braking systems, suspension systems, and auxiliary equipment 2.

Purpose of the Cummins 5398515 Air Compressor

This Cummins part plays a role in the operation of a truck by generating compressed air. This compressed air is utilized by various truck systems, including the braking system, suspension system, and auxiliary equipment. The compressor ensures that these systems have a reliable source of pressurized air, which is crucial for their operation.

Key Features

This part is characterized by its robust design and construction. It is built using high-quality materials to ensure durability and reliability. The compressor incorporates technological advancements that enhance its performance and efficiency. These features contribute to its ability to meet the demanding requirements of commercial truck operations.

Benefits

The Cummins 5398515 Air Compressor offers several advantages. It provides improved efficiency in truck operations by ensuring a consistent supply of compressed air. Its reliable performance contributes to the overall reliability of the truck. Additionally, the compressor enhances the performance of various truck systems by providing them with the necessary pressurized air.

Installation and Integration

Proper installation and integration of this part into a truck’s system are crucial for its optimal performance. This process involves following manufacturer guidelines to ensure that the compressor is correctly installed and integrated. Preparations may include ensuring that the truck’s system is compatible with the compressor and that all necessary components are in place.

Operational Efficiency

This part contributes to the overall operational efficiency of a truck. By providing a reliable source of compressed air, it supports the efficient operation of various truck systems. This can lead to improved fuel economy and enhanced system performance, ultimately contributing to the truck’s operational efficiency.

Common Applications

Within the commercial trucking industry, this part is commonly used in braking systems, suspension systems, and auxiliary equipment. Its role in these systems is to provide the necessary pressurized air for their operation. This makes it a versatile component that is integral to the functioning of commercial trucks.

Troubleshooting and Maintenance

To ensure optimal performance and longevity, it is important to address common issues that may arise with this part. Troubleshooting may involve checking for leaks, ensuring proper lubrication, and monitoring the compressor’s performance. Regular maintenance practices, such as cleaning and inspecting the compressor, can help prevent issues and ensure its reliable operation.

Safety Considerations

When working with this part, it is important to observe safety precautions. This includes proper handling, installation, and maintenance procedures. Following manufacturer guidelines and using appropriate personal protective equipment can help ensure a safe working environment.

Environmental Impact

The use of this part has an environmental impact, primarily through emissions and energy consumption. Efforts to minimize this impact may include using energy-efficient compressors, implementing maintenance practices that reduce emissions, and considering the environmental implications of compressor use in truck operations.

Cummins Overview

Cummins Inc. is a company with a long-standing reputation in the automotive and commercial vehicle industries. Founded with a mission to power a more prosperous world, Cummins has a history of innovation and quality. The company’s commitment to excellence is reflected in its products, including the Cummins 5398515 Air Compressor, which is designed to meet the demanding requirements of commercial truck operations 3.

Cummins Air Compressor Part 5398515 Compatibility

The Cummins air compressor part 5398515 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is specifically engineered to work with the following engines:

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

These engines, while distinct in their specific configurations, share common design elements that allow the air compressor part 5398515 to integrate effectively. The compatibility of this part with these engines underscores its versatility and the precision with which it has been manufactured. By ensuring a precise fit, this air compressor part contributes to the overall efficiency and longevity of the engines it supports.

Role of Part 5398515 Air Compressor in Engine Systems

The air compressor, identified by part number 5398515, is integral to the efficient operation of various engine systems. It works in conjunction with several key components to ensure optimal performance and reliability.

Intercooler System

In turbocharged and supercharged engines, the air compressor plays a significant role in the intercooler system. After the air is compressed, it becomes hot, which can reduce its density and efficiency. The intercooler cools this compressed air before it enters the engine, allowing for denser air intake and improved combustion efficiency. The air compressor ensures a steady supply of compressed air that the intercooler can effectively cool.

Fuel Injection System

Modern fuel injection systems rely on precise air-fuel ratios for optimal combustion. The air compressor provides a consistent flow of compressed air, which is essential for the fuel injectors to meter the correct amount of fuel. This results in better fuel economy and reduced emissions. The compressor’s role is to maintain the necessary air pressure and volume that the fuel injection system requires.

Emission Control System

Emission control systems, including catalytic converters and exhaust gas recirculation (EGR) systems, depend on the quality and quantity of air supplied by the compressor. Efficient air compression ensures that the catalytic converter operates within its optimal temperature range, effectively reducing harmful emissions. Additionally, the EGR system uses compressed air to recirculate a portion of the exhaust gases back into the intake manifold, which helps in lowering nitrogen oxides (NOx) emissions.

Engine Breathing

The air compressor enhances engine breathing by providing a robust intake of air. This is particularly important in high-performance engines where the demand for air is significantly higher. The compressor ensures that the engine receives the necessary air volume to meet its power requirements, thereby improving overall engine performance and responsiveness.

Turbocharger and Supercharger Systems

In forced induction systems, the air compressor works alongside turbochargers and superchargers to boost engine performance. It provides the initial compression of air that these systems further enhance. This synergy allows for greater air density and, consequently, more power output without significantly increasing engine size.

Cabin Air System

In some applications, the air compressor also feeds into the cabin air system, providing pressurized air for heating, ventilation, and air conditioning (HVAC). This ensures a comfortable environment for occupants while the engine operates efficiently.

Conclusion

The air compressor, part number 5398515, is a versatile component that interacts with multiple engine systems to enhance performance, efficiency, and emissions control. Its role in providing consistent and pressurized air is fundamental to the operation of modern engine technologies.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.