This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

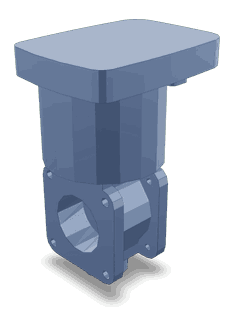

The Cummins 5398550 Air-Fuel Throttle Valve is designed to optimize the air-fuel mixture in heavy-duty truck engines. This component enhances engine performance, improves fuel efficiency, and ensures compliance with emissions standards. By facilitating precise control over the air-fuel ratio, this valve is integral to efficient combustion and overall engine health 1.

Basic Concepts of Air-Fuel Throttle Valves

An Air-Fuel Throttle Valve regulates the flow of air and fuel into an engine’s combustion chamber. It adjusts the throttle position to control the amount of air entering the engine, which in turn affects fuel delivery. This ensures the engine receives the optimal air-fuel mixture for combustion, maximizing power output, fuel efficiency, and reducing emissions 2.

Purpose and Role in Truck Operation

The Cummins 5398550 is engineered to meet the demanding requirements of heavy-duty truck engines. It ensures precise control of the air-fuel mixture under various operating conditions, resulting in improved fuel efficiency and reduced emissions. This valve helps manage emissions by ensuring complete combustion, thereby reducing harmful pollutants 3.

Key Features

The Cummins 5398550 boasts several key features that enhance its performance and durability. These include a robust design capable of withstanding high temperatures and pressures, construction from high-quality materials for longevity, and precise throttle control mechanisms with advanced sensor integration for accurate air-fuel mixture adjustments 4.

Benefits

Utilizing the Cummins 5398550 offers several benefits. It improves engine efficiency by optimizing the air-fuel mixture, leading to reduced fuel consumption and lower operating costs. It enhances drivability with smooth and responsive throttle control and plays a role in reducing emissions, contributing to environmental sustainability and regulatory compliance 5.

Installation and Integration

Proper installation and integration of the Cummins 5398550 are crucial for optimal performance. It is important to follow manufacturer guidelines to ensure compatibility with specific engine models. Any necessary adjustments or configurations should be made according to the provided instructions to ensure the valve operates correctly within the engine system 6.

Troubleshooting and Maintenance

Common issues with the Cummins 5398550 may include throttle response problems or irregularities in engine performance. Troubleshooting steps involve checking for proper installation, ensuring all connections are secure, and verifying that the valve is functioning within specified parameters. Regular maintenance practices, such as cleaning and inspecting the valve for wear or damage, are recommended to ensure continued optimal performance and longevity 7.

Performance and Efficiency

The Cummins 5398550 has a notable impact on engine performance and fuel efficiency. Trucks equipped with this valve have shown measurable improvements in fuel economy and engine responsiveness. The precise control over the air-fuel mixture allows for more efficient combustion, translating to better overall engine performance and reduced fuel consumption 8.

Regulatory Compliance and Emissions

The Cummins 5398550 plays a role in helping heavy-duty trucks meet emissions regulations and standards. By optimizing the air-fuel mixture for complete combustion, the valve contributes to reducing the output of harmful emissions. This is particularly important in the commercial trucking industry, where compliance with environmental regulations is a priority 9.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive industry. Known for its commitment to innovation and quality, Cummins has a long history of manufacturing reliable and high-performance automotive components. The company’s dedication to advancing technology and meeting customer needs is evident in its wide range of products, including the Cummins 5398550 Air-Fuel Throttle Valve 10.

Compatibility

The Cummins Air-Fuel Throttle Valve part number 5398550 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and efficiency. This part is crucial for controlling the air-fuel mixture entering the engine, which directly impacts the engine’s power output and fuel economy.

L8.9G Engine

The L8.9G engine is a robust and reliable power unit, often used in heavy-duty applications. The 5398550 throttle valve is engineered to fit this engine, providing precise control over the air-fuel mixture. This ensures that the engine operates at peak efficiency, maintaining consistent performance even under heavy loads.

CMOH2.0 and L125B Engines

The CMOH2.0 and L125B engines, while differing in their specific applications, both benefit from the precise control offered by the 5398550 throttle valve. This part is designed to integrate smoothly with these engines, ensuring that the air-fuel mixture is regulated to the exact specifications required for optimal performance. The compatibility of this valve with these engines highlights its versatility and importance in maintaining engine efficiency and reliability.

By ensuring that the air-fuel mixture is correctly managed, the 5398550 throttle valve plays a critical role in the overall performance and longevity of these engines. Its design allows for easy installation and reliable operation, making it a vital component for maintaining the efficiency and power of Cummins engines.

Role in Engine Systems

The 5398550 Air-Fuel Throttle Valve is an integral component within the engine systems, specifically interacting with the module and fuel control systems.

Interaction with the Module

The module, often an electronic control unit (ECU), relies on precise data inputs to manage engine performance. The Air-Fuel Throttle Valve provides real-time feedback on air and fuel mixture ratios. This data is essential for the module to make accurate adjustments to the engine’s operation, ensuring optimal performance and efficiency. The valve’s ability to modulate the air-fuel mixture allows the module to fine-tune parameters such as ignition timing and fuel injection duration, leading to improved engine responsiveness and reduced emissions.

Integration with Fuel Control

In the fuel control system, the Air-Fuel Throttle Valve plays a significant role in maintaining the correct air-fuel ratio. This valve adjusts the airflow into the engine, which directly influences how the fuel is combusted. By working in tandem with the fuel injectors, the valve ensures that the fuel is atomized properly and mixed with the right amount of air. This precise control is vital for achieving the desired power output while minimizing fuel consumption and pollutants. The valve’s responsive design allows for dynamic adjustments, accommodating varying engine loads and operating conditions.

Overall, the 5398550 Air-Fuel Throttle Valve enhances the functionality of both the module and fuel control systems, contributing to a more efficient and responsive engine performance.

Conclusion

The Cummins 5398550 Air-Fuel Throttle Valve is a critical component for optimizing engine performance, fuel efficiency, and emissions compliance in heavy-duty trucks. Its robust design, precise control mechanisms, and compatibility with various Cummins engines make it an essential part for maintaining engine efficiency and reliability. Proper installation, regular maintenance, and understanding its role within the engine systems are key to leveraging its full benefits.

-

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Huzij, Robert, Spano, Angelo, & Bennett, Sean. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358483.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Huzij, Robert, Spano, Angelo, & Bennett, Sean. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358483.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Vocational Vehicles and Applications. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.