This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

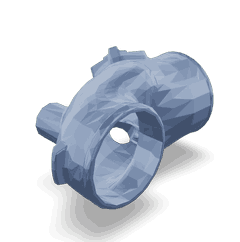

The Cummins 5411675 Air Inlet Pipe is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the flow of air into the engine, which is a fundamental aspect of the truck’s operation. This part is integral to ensuring that the engine receives a consistent and adequate supply of air, which is necessary for combustion and overall engine performance 1.

Basic Concepts of Air Inlet Pipes

An air inlet pipe is a conduit that directs air from the outside environment into the engine’s intake system. Its function within the engine system is to provide a pathway for air to travel from the air filter to the turbocharger or directly to the engine’s cylinders. The air inlet pipe contributes to the overall performance of the truck by ensuring that the engine operates with the correct air-fuel mixture, which is vital for efficient combustion and power output 2.

Purpose of the Cummins 5411675 Air Inlet Pipe

The Cummins 5411675 Air Inlet Pipe plays a specific role in the truck’s engine system by guiding air from the air filter to the turbocharger or engine intake. This part is designed to handle the high pressures and temperatures associated with the air intake process in a heavy-duty truck engine. By providing a smooth and unobstructed path for air, it helps maintain engine efficiency and performance 3.

Key Features

The Cummins 5411675 Air Inlet Pipe is constructed from durable materials that can withstand the rigors of heavy-duty truck operation. Its design includes features such as reinforced joints and a smooth interior to reduce turbulence and ensure a steady airflow. Additionally, the pipe may incorporate heat shielding to protect against the high temperatures generated by the engine and exhaust system, which helps maintain the integrity of the air entering the engine.

Benefits

The Cummins 5411675 Air Inlet Pipe offers several benefits, including improved engine efficiency due to its design that minimizes air resistance. Its durable construction contributes to the longevity of the component, reducing the need for frequent replacements. Furthermore, the pipe’s ability to handle high pressures and temperatures ensures that it can operate effectively under a wide range of conditions, which is particularly important for heavy-duty trucks that often work in demanding environments.

Installation Considerations

When installing the Cummins 5411675 Air Inlet Pipe, it is important to follow the manufacturer’s guidelines to ensure proper fitment and function. This may include checking for any obstructions in the path of the pipe, ensuring that all connections are secure, and verifying that the pipe is correctly aligned with the air filter and engine intake. Cummins may provide specific recommendations for torque settings and the use of sealants or clamps to ensure a leak-free installation.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 5411675 Air Inlet Pipe involves inspecting it for signs of wear, cracks, or leaks. It is also important to check the connections for tightness and ensure that there are no obstructions in the pipe that could restrict airflow. Troubleshooting common issues such as leaks or blockages may involve tightening connections, replacing damaged sections, or cleaning the interior of the pipe to remove any debris that could impede airflow.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the heavy-duty truck industry. The company’s product range includes engines and components that are known for their reliability, performance, and durability, making them a preferred choice for commercial vehicle operators worldwide.

Role of Part 5411675 Air Inlet Pipe in Engine Systems

The Air Inlet Pipe (Part 5411675) is a critical component in the air induction system of an engine. Its primary function is to direct air from the Air Cleaner to the engine’s intake manifold. This part ensures a smooth and uninterrupted flow of clean air, which is vital for optimal engine performance.

Integration with Key Components

-

Air Cleaner: The air inlet pipe connects directly to the air cleaner, which filters out contaminants from the incoming air. This filtered air is then channeled through the pipe to the engine.

-

Plumbing: The air inlet pipe is part of the engine’s air induction plumbing. It works in conjunction with other plumbing components to maintain a sealed and efficient air pathway. This helps in preventing any air leaks that could affect engine efficiency and performance.

-

Intake Manifold: The pipe terminates at the intake manifold, where the clean air mixes with fuel before entering the combustion chambers. The design and placement of the air inlet pipe ensure that air reaches the manifold with minimal turbulence, contributing to better fuel-air mixture and combustion efficiency.

Functional Synergy

The air inlet pipe’s role extends beyond simple air conveyance. It is engineered to withstand the vibrations and thermal cycles experienced within the engine compartment. Its design also considers the acoustic properties to reduce noise transmission from the intake system to the passenger compartment.

Conclusion

In summary, the Cummins 5411675 Air Inlet Pipe plays a significant role in maintaining the integrity and efficiency of the air induction system. Its seamless integration with the air cleaner and intake manifold ensures that the engine receives a consistent supply of clean, unfiltered air, which is essential for reliable and efficient operation.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems (SAE International, 2020).

↩ -

A. J. Wharton, Diesel Engines (Butterworth-Heinemann Ltd, 1991).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.