This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

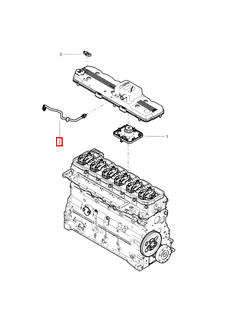

The Air Transfer Tube (Part #5444979) by Cummins is a component designed for use in commercial trucks. It facilitates the movement of air within the truck’s air system, contributing to various operational functions. This Cummins part is integral to maintaining the efficiency and reliability of the truck’s air-operated systems.

Basic Concepts and Functionality

The Air Transfer Tube operates on the fundamental principle of pneumatics, utilizing compressed air to perform work 1. Within the truck’s air system, it connects to other components such as air tanks, valves, and actuators. Its role is to convey air from the compressor to these components, ensuring they receive the necessary air pressure to function correctly. The tube interacts with the system’s various parts, allowing for the distribution of air as needed for braking, suspension, and other air-dependent operations.

Purpose and Role in Truck Operation

In a commercial truck, the Air Transfer Tube serves several functions. Primarily, it is responsible for the distribution of compressed air throughout the vehicle. This air is vital for the operation of the braking system, suspension adjustments, and other pneumatic controls. By ensuring a consistent and reliable air supply, the tube contributes to the overall efficiency and safety of the truck’s operations 2.

Key Features

The Air Transfer Tube is characterized by several key features that enhance its performance. It is typically made from durable materials resistant to the high pressures and temperatures within the air system. The design of the tube includes reinforced connections to prevent leaks and ensure a secure fit within the system. Additionally, it may feature smooth internal surfaces to minimize air resistance and maximize flow efficiency.

Benefits

The advantages of the Air Transfer Tube include improved airflow within the truck’s air system, leading to more efficient operation of air-dependent components. Its durable construction ensures longevity, reducing the need for frequent replacements. Furthermore, the tube’s reliable performance contributes to the overall system reliability, enhancing the truck’s operational safety and efficiency.

Installation and Integration

Proper installation of the Air Transfer Tube is crucial for its effective operation. It should be fitted according to the manufacturer’s guidelines to ensure compatibility with the truck’s air system. This includes verifying the correct orientation and secure connection to other components. Careful attention to these details during installation will help maintain the integrity of the air system and ensure the tube functions as intended 3.

Maintenance and Troubleshooting

Routine maintenance of the Air Transfer Tube involves checking for signs of wear, leaks, or damage. Regular inspections can help identify issues before they lead to system failures. Troubleshooting common problems may include verifying connections, testing for leaks, and ensuring the tube is free from obstructions. Prompt attention to these maintenance practices can extend the life of the tube and maintain system performance.

Safety Considerations

When handling and working with the Air Transfer Tube, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment, ensuring the air system is depressurized before beginning work, and following all manufacturer guidelines for installation and maintenance. These precautions help prevent accidents and ensure safe operation of the truck’s air system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Air Transfer Tube Component Usage

This part is an essential component in the efficient operation of various engine systems, particularly in managing the airflow within the breather and crankcase systems.

In the breather system, the Air Transfer Tube facilitates the controlled exchange of air between the engine’s internal components and the atmosphere. This exchange is vital for maintaining optimal pressure levels within the engine, ensuring that the breather can effectively vent excess pressure and moisture. By allowing fresh air to enter and stale air to exit, the tube helps in preventing the buildup of contaminants and moisture, which can lead to corrosion and reduced engine performance.

Within the crankcase system, the Air Transfer Tube plays a significant role in managing the airflow that affects the crankcase ventilation. The crankcase accumulates gases and vapors as a byproduct of the combustion process. The tube aids in the efficient removal of these gases, directing them to the intake system where they can be re-burned. This not only helps in reducing emissions but also ensures that the crankcase operates under the correct pressure, which is essential for the proper functioning of the engine’s moving parts.

Overall, the Air Transfer Tube is integral to the smooth operation of these systems, contributing to the engine’s durability, performance, and environmental compliance.

Conclusion

The 5444979 Air Transfer Tube by Cummins is a critical component in the operation of commercial trucks, ensuring efficient airflow within the air system. Its durable construction, key features, and reliable performance contribute to the overall safety and efficiency of the truck’s operations. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this part.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2670 L134C. Bulletin Number 5579951.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.