This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

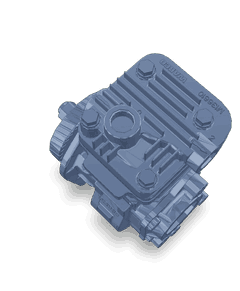

The Cummins 5562847 Air Compressor is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by providing the necessary air pressure for various systems. Understanding its function and importance can help fleet managers and technicians maintain optimal truck performance.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. It works by drawing in air, compressing it, and storing it in a tank until needed. In commercial trucks, air compressors are used for a variety of applications, including powering brakes, suspensions, and other pneumatic systems 1.

Purpose of the Cummins 5562847 Air Compressor

This Cummins part plays a role in the operation of a truck by generating and maintaining the air pressure required for various systems. It ensures that the air brake system, suspension systems, and other pneumatic components function correctly. By providing consistent air pressure, it contributes to the safe and efficient operation of the vehicle.

Key Features

This part is characterized by several key features. Its design is robust, built to withstand the demanding conditions of commercial truck operations. The compressor is known for its high build quality, ensuring durability and reliability. Unique characteristics include advanced engineering that enhances efficiency and performance.

Benefits

Using this part offers several benefits. It provides improved efficiency in air pressure generation, which can lead to better overall truck performance. The compressor is designed for reliability, reducing the likelihood of downtime due to compressor failure. Additionally, its performance contributes to the smooth operation of pneumatic systems in the truck.

Installation Process

Installing this part involves several steps. First, ensure that the truck is parked on a level surface and the engine is off. Gather the necessary tools, which may include wrenches, hose clamps, and a pressure gauge. Follow the manufacturer’s instructions for disconnecting the old compressor and connecting the new one, ensuring all connections are secure and there are no leaks in the system.

Common Applications

This part is commonly used in various types of commercial trucks, including semi-trucks, dump trucks, and vocational vehicles. It is suitable for fleet operations that require reliable air pressure for braking, suspension, and other pneumatic systems. Its versatility makes it a popular choice for many commercial truck applications.

Troubleshooting and Maintenance

To troubleshoot common issues with this part, start by checking for air leaks in the system, ensuring all connections are tight. Regularly inspect the compressor for signs of wear or damage. Maintenance tips include keeping the compressor clean, checking the belt tension, and ensuring the cooling system is functioning correctly to prevent overheating.

Safety Considerations

When installing, maintaining, or troubleshooting this part, it is important to follow safety precautions. Ensure the truck is parked in a safe area, use the appropriate personal protective equipment, and follow all manufacturer guidelines. Be aware of the high pressure in the air system and take care to avoid injuries from sudden releases of pressurized air.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing high-quality components that enhance the performance and reliability of commercial vehicles.

Cummins Air Compressor Part 5562847 Compatibility

This part is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to work with the following engine models:

- 4B3.9

- 6B5.9

- B5.9 GAS PLUS CM556

These engines, while differing in their specific configurations and applications, share a commonality in their need for a robust air compressor system. This part is meticulously crafted to meet the demands of these engines, providing efficient air compression necessary for various engine functions.

For the 4B3.9 and 6B5.9 engines, this part is integral to maintaining the air supply required for the engine’s operation. This ensures that the engine runs smoothly and efficiently, reducing the likelihood of air-related issues.

In the case of the B5.9 GAS PLUS CM556, this part is specifically tailored to handle the unique demands of this engine model. The part’s design accommodates the specific air requirements of the B5.9 GAS PLUS CM556, ensuring that it operates at peak performance levels.

By integrating this part into these engines, users can expect enhanced reliability, improved efficiency, and a reduction in maintenance needs. This part is a critical component in the overall health and performance of the engines it supports.

Role of Part 5562847 Air Compressor in Engine Systems

The integration of this part within engine systems is fundamental for maintaining optimal performance and efficiency. This component is primarily responsible for generating the pressurized air required by various engine subsystems.

Fuel Injection Systems

In fuel injection systems, the pressurized air supplied by the Air Compressor is essential for atomizing the fuel. This process ensures a finer fuel spray, which enhances combustion efficiency and reduces emissions. The consistent air pressure provided by the compressor contributes to stable fuel delivery and improved engine responsiveness.

Turbocharger Systems

When paired with turbochargers, the Air Compressor plays a significant role in boosting engine power. The compressed air increases the density of the air entering the combustion chamber, allowing for more fuel to be burned and thus generating more power. This synergy between the compressor and turbocharger results in enhanced engine performance and efficiency.

Brake Systems

In brake systems that utilize compressed air, such as those found in heavy-duty vehicles, the Air Compressor is vital for maintaining the necessary air pressure. This ensures that the brakes operate effectively under various conditions, providing reliable stopping power and safety.

Pneumatic Tools and Accessories

Many engine systems incorporate pneumatic tools and accessories that rely on compressed air. The Air Compressor supplies the required air pressure for these tools, enabling mechanics to perform maintenance and repairs efficiently. This integration streamlines workshop operations and enhances overall productivity.

Cabin Pressurization Systems

In applications where cabin pressurization is necessary, such as in certain types of engines used in aviation or specialized vehicles, the Air Compressor ensures that the cabin remains pressurized. This is essential for occupant comfort and safety, particularly at high altitudes or in environments with low atmospheric pressure.

Emission Control Systems

Modern emission control systems often require precise air pressure for various components, such as air-assisted injectors and secondary air injection systems. The Air Compressor provides the consistent and reliable air pressure needed to ensure these systems operate effectively, helping to meet stringent emission regulations.

Cooling Systems

Some engine cooling systems utilize compressed air for enhanced heat dissipation. The Air Compressor supplies the necessary air pressure to these systems, improving their efficiency and contributing to the overall thermal management of the engine.

Conclusion

In summary, the Cummins 5562847 Air Compressor is a versatile component that supports a wide range of engine subsystems, ensuring they function optimally and contribute to the engine’s overall performance and reliability. Its robust design, advanced engineering, and compatibility with various Cummins engines make it a critical component for commercial truck operations.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.