This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

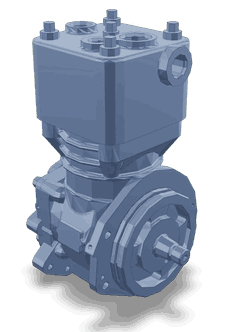

The Cummins 5583505 Air Compressor is a component designed for use in commercial trucks. It serves to generate compressed air, which is vital for the operation of various truck systems. This compressor is significant in ensuring the efficient and reliable performance of trucks, particularly in applications requiring robust pneumatic systems.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. It operates by drawing in air, compressing it, and then storing it in a tank until needed. In a truck’s pneumatic system, compressed air is used to power brakes, suspension systems, and various auxiliary functions. There are several types of air compressors, including reciprocating, rotary screw, and centrifugal, each with specific applications and efficiencies. In commercial vehicles, the choice of compressor depends on factors such as required air volume, pressure, and the specific needs of the vehicle’s systems 1.

Purpose of the Cummins 5583505 Air Compressor

This Cummins part plays a role in supplying compressed air for critical truck systems. It ensures that the braking system operates effectively, provides air for the suspension system to maintain vehicle stability, and supports auxiliary functions such as air horns and pneumatic tools. The compressor’s ability to deliver consistent and reliable compressed air is fundamental to the safe and efficient operation of commercial trucks.

Key Features

The Cummins 5583505 Air Compressor is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and performance. It incorporates advanced technological features that enhance its efficiency and reliability. These features include precision-engineered components, optimized airflow design, and integrated safety mechanisms. Such attributes contribute to the compressor’s ability to operate under demanding conditions, providing consistent performance and longevity.

Benefits

This part offers several benefits, including improved efficiency, reliability, and performance. Its design allows for efficient air compression, reducing energy consumption and operational costs. The compressor’s reliability ensures minimal downtime and maintenance requirements, contributing to the overall efficiency of truck operations. Additionally, its performance capabilities support the demanding requirements of commercial truck applications, enhancing safety and operational effectiveness.

Installation and Integration

When installing the Cummins 5583505 Air Compressor, it is important to consider compatibility with the truck’s model and existing pneumatic systems. Proper installation involves securing the compressor in a suitable location, ensuring adequate airflow and ventilation, and connecting it to the truck’s air system. Integration with existing systems requires careful planning to ensure seamless operation and optimal performance.

Troubleshooting and Maintenance

Common issues with the Cummins 5583505 Air Compressor may include leaks, unusual noises, or a decrease in performance. Troubleshooting steps involve inspecting for leaks, checking connections, and ensuring the compressor is operating within specified parameters. Regular maintenance, such as cleaning filters, inspecting belts and hoses, and replacing worn components, is crucial for maintaining optimal performance and longevity.

Performance and Efficiency

The Cummins 5583505 Air Compressor is designed to deliver high performance and efficiency. Its performance metrics and efficiency ratings are competitive within the market, offering advantages such as lower energy consumption and higher output. When compared to other similar air compressors, the Cummins 5583505 stands out for its reliability, durability, and advanced technological features.

Safety Considerations

When working with the Cummins 5583505 Air Compressor, it is important to adhere to safety guidelines and precautions. This includes ensuring proper ventilation, using protective equipment, and following manufacturer recommendations for operation and maintenance. Awareness of potential hazards, such as high-pressure air leaks or electrical risks, and taking steps to mitigate them, ensures safe operation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry, Cummins is committed to innovation and quality in manufacturing components for commercial trucks. Their products are known for reliability, performance, and durability, contributing to the efficiency and safety of commercial vehicle operations.

Compatibility with Cummins Engines

This part is designed to integrate seamlessly with a variety of Cummins engines. It is crucial for maintaining the air supply necessary for the engine’s operation, ensuring optimal performance and reliability.

F2.8 CM2620

The F2.8 CM2620 engine benefits from the 5583505 Air Compressor due to its robust design and compatibility with the engine’s specifications. This air compressor ensures that the engine receives a consistent and adequate air supply, which is vital for its performance and longevity.

F135B

Similarly, the F135B engine is engineered to work efficiently with the 5583505 Air Compressor. This part’s integration with the F135B engine enhances the engine’s ability to maintain the required air pressure, contributing to its overall operational efficiency and reliability.

Grouping of Engines

The 5583505 Air Compressor is versatile and can be used across multiple Cummins engines, including the F2.8 CM2620 and F135B. This compatibility is due to the part’s standardized design and engineering, which ensures it meets the necessary specifications for these engines. The seamless integration of this air compressor with these engines highlights its importance in maintaining the engine’s performance and reliability.

Role in Engine Systems

The integration of this part within engine systems is fundamental for the efficient operation of various components. This air compressor is responsible for generating the necessary pressurized air that powers several critical systems.

Fuel Injection Systems

In fuel injection systems, the pressurized air from the air compressor is essential for atomizing the fuel. This ensures a fine mist of fuel is delivered into the combustion chamber, promoting more efficient and complete combustion. The enhanced air-fuel mixture leads to improved engine performance and reduced emissions 2.

Brake Systems

For brake systems, particularly in vehicles equipped with air brakes, the air compressor plays a vital role. It generates the compressed air required to operate the brake cylinders. This ensures that the braking force is applied consistently and reliably, enhancing vehicle safety and control.

Suspension Systems

In air suspension systems, the air compressor is used to adjust the ride height of the vehicle. By varying the air pressure in the suspension components, it allows for a smoother ride and better handling. This adaptability is particularly beneficial in off-road conditions or when carrying heavy loads.

Pneumatic Tools

Many engine systems incorporate pneumatic tools for maintenance and repair tasks. The air compressor provides the necessary air pressure to operate these tools efficiently. This includes everything from drills to grinders, ensuring that maintenance tasks are performed quickly and effectively.

Cabin Pressurization

In certain engine systems, especially those found in aircraft, the air compressor is used for cabin pressurization. It ensures that the air inside the cabin remains at a comfortable and safe pressure, regardless of the external atmospheric conditions. This is essential for the well-being of passengers and crew during flight.

Cooling Systems

Some engine cooling systems utilize compressed air to enhance heat dissipation. The air compressor provides the additional airflow needed to cool critical components, preventing overheating and ensuring optimal engine performance.

Pneumatic Actuators

Pneumatic actuators in engine systems rely on the air compressor to function. These actuators are used in various applications, from controlling valves to operating mechanical systems. The consistent supply of pressurized air ensures that these actuators respond quickly and reliably.

Conclusion

In summary, the Cummins 5583505 Air Compressor is a versatile component that supports a wide range of engine systems, contributing to their efficiency, safety, and performance. Its robust design, advanced features, and compatibility with various Cummins engines make it a critical component for the reliable operation of commercial trucks and other heavy-duty vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.