5658312

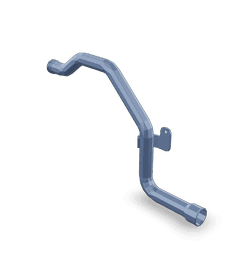

Compressor Air Inlet Tube

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Air Inlet Tube, identified by part number 5658312, is a component manufactured by Cummins, a leader in diesel engine technology. This tube is integral to the compressed air system of heavy-duty trucks, facilitating efficient airflow into the compressor. Its design and function are tailored to enhance the performance and reliability of the truck’s air system.

Basic Concepts

Understanding the operation of the Compressor Air Inlet Tube requires a grasp of airflow dynamics within the compressed air system. The tube serves as a conduit for air entering the compressor, where it is pressurized before being distributed throughout the truck’s systems. The design of the tube influences the efficiency of this airflow, impacting the overall performance of the compressed air system 1.

Purpose and Function

The Compressor Air Inlet Tube plays a role in the operation of a truck by directing ambient air into the compressor. This air is then pressurized and used for various functions, including braking systems, suspension, and other pneumatic controls. The tube’s design contributes to the efficiency and performance of the compressed air system by ensuring a smooth and unrestricted flow of air into the compressor 2.

Key Features

The 5658312 Compressor Air Inlet Tube is characterized by several key features that enhance its performance and durability. These include a robust material composition designed to withstand the harsh conditions of heavy-duty truck environments, a design that minimizes airflow resistance, and unique attributes such as reinforced joints or coatings that protect against wear and corrosion.

Benefits

The advantages of the 5658312 Compressor Air Inlet Tube include improved airflow efficiency, which contributes to the overall efficiency of the compressed air system. Enhanced airflow can lead to better performance of truck systems reliant on compressed air, potentially improving the truck’s operational reliability and performance. Additionally, the tube’s durable construction helps ensure longevity and resistance to the demanding conditions encountered in heavy-duty applications.

Installation and Integration

Proper installation of the Compressor Air Inlet Tube is vital for ensuring its effective operation within the truck’s compressed air system. Installation procedures should include thorough cleaning of the installation area, careful alignment of the tube with the compressor inlet, and secure fastening to prevent leaks or disconnections. Tools required may include wrenches, sealants, and possibly specialized fittings to ensure a snug and leak-free connection.

Maintenance and Care

To prolong the lifespan and maintain the optimal performance of the Compressor Air Inlet Tube, routine maintenance practices are recommended. These include regular cleaning to remove any debris or contaminants that could obstruct airflow, periodic inspection for signs of wear or damage, and adherence to replacement schedules based on the manufacturer’s guidelines or operational conditions.

Troubleshooting Common Issues

Common issues associated with the Compressor Air Inlet Tube may include leaks, blockages, or material degradation. Diagnostic steps to identify these problems involve checking for visible signs of damage, testing for leaks in the compressed air system, and assessing the tube’s condition for wear or corrosion. Repair or replacement procedures should follow manufacturer recommendations to ensure the tube’s continued efficient operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to advancing engine technology is evident in its wide range of products, including the Compressor Air Inlet Tube, designed to meet the demanding requirements of heavy-duty applications 3.

Compatibility of Compressor Air Inlet Tube 5658312 with Cummins Engines

The Compressor Air Inlet Tube 5658312, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. Specifically, this part is compatible with the following engine models:

- X15 CM2350 X123B

- X15 CM2350 X116B

- X15 CM2450 X134B

These engines, while sharing common features, are part of a series that includes variations in their specifications and configurations. The Compressor Air Inlet Tube 5658312 is engineered to ensure optimal performance and compatibility across these models. It is crucial to verify the correct fitment of this part with the specific engine model to ensure proper function and longevity of the engine components.

Role of Part 5658312 Compressor Air Inlet Tube in Engine Systems

The part 5658312 Compressor Air Inlet Tube is an integral component in the efficient operation of the compressor air inlet arrangement and compressor air inlet plumbing within engine systems.

In the compressor air inlet arrangement, the Compressor Air Inlet Tube directs the flow of air from the external environment into the compressor section of the engine. This tube ensures that the air entering the compressor is clean and free from debris, which is essential for maintaining the performance and longevity of the compressor blades. The precise alignment and secure fitting of the tube within this arrangement prevent any potential air leaks, which could otherwise lead to a decrease in compressor efficiency and overall engine performance.

Within the compressor air inlet plumbing, the Compressor Air Inlet Tube plays a significant role in maintaining the integrity of the air supply system. It connects various components such as filters, sensors, and valves, ensuring a seamless and uninterrupted flow of air. The tube’s design allows for easy integration with other plumbing components, facilitating maintenance and replacement procedures when necessary. Additionally, it helps in regulating the pressure and temperature of the incoming air, contributing to the stable operation of the engine under varying conditions.

Conclusion

The Compressor Air Inlet Tube, part number 5658312, is a critical component in the compressed air system of heavy-duty trucks, designed to enhance the efficiency and reliability of the system. Its robust design, compatibility with various Cummins engines, and role in maintaining the integrity of the air supply system underscore its importance in ensuring optimal engine performance.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

The Drivers Cab, Michael Hilgers, Springer Vieweg, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.