This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

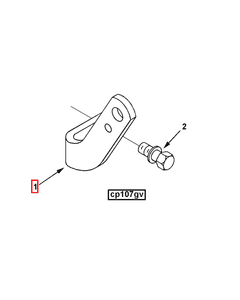

The 3412324 Air Compressor Brace, manufactured by Cummins, is a component designed to enhance the operational efficiency of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of components aimed at improving the performance and reliability of truck systems. This part is significant in commercial truck operations as it plays a role in supporting the air compressor, which is vital for various truck functions including braking systems and pneumatic controls 1.

Purpose and Function

This Cummins part is designed to support the air compressor within the truck’s system. It contributes to the stability and efficiency of the air compressor by providing a secure mounting point. This support helps in minimizing movement and vibration, which can otherwise lead to wear and tear on the compressor and connected components. By ensuring the compressor remains firmly in place, the brace aids in maintaining consistent performance and longevity of the air compressor 2.

Key Features

The 3412324 is constructed with materials that offer high strength and durability. It is typically made from steel or a similar robust material, ensuring it can withstand the rigors of commercial truck operations. The design of the brace includes features that enhance its structural integrity, such as reinforced mounting points and a solid frame. These design elements are intended to provide maximum support to the air compressor while maintaining a compact and efficient form factor 3.

Benefits

Using the Air Compressor Brace offers several advantages. It contributes to the improved durability of the air compressor by reducing the stress and vibration that can lead to premature wear. Additionally, the brace helps in enhancing the overall performance of the truck’s air system by ensuring the compressor operates within optimal parameters. This can lead to more reliable air supply for critical systems such as brakes and pneumatic controls.

Installation Process

Installing the 3412324 requires careful attention to detail to ensure it is correctly positioned and secured. The process involves identifying the appropriate mounting points on the truck’s frame and compressor. Once positioned, the brace should be secured using the recommended fasteners and tools. It is important to follow the manufacturer’s guidelines to ensure the brace is installed correctly and functions as intended.

Maintenance and Troubleshooting

Regular maintenance of the Air Compressor Brace is important to ensure its longevity and effectiveness. This includes checking for any signs of wear or damage, ensuring all fasteners are tight, and verifying that the brace remains securely mounted. Common issues that may arise include loosening of fasteners or damage to the brace itself. Troubleshooting steps may involve tightening fasteners, repairing or replacing damaged components, and ensuring the brace is correctly aligned with the compressor and truck frame.

Safety Considerations

When installing or maintaining the Air Compressor Brace, it is important to observe safety protocols and precautions. This includes ensuring the truck is securely parked and the engine is off before beginning any work. Additionally, it is crucial to use the correct tools and equipment as specified by the manufacturer to avoid damage to the brace or injury to the technician. Adhering to manufacturer guidelines and industry standards is paramount to ensuring a safe and effective installation and maintenance process.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various industries, with a strong emphasis on reliability, performance, and customer satisfaction. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that its components, including the Air Compressor Brace, meet the high standards required for commercial truck applications.

Compatibility

The Cummins Air Compressor Brace, identified by part number 3412324, is designed to support and secure the air compressor within various engine configurations. This part is engineered to ensure the stability and proper functioning of the air compressor, which is essential for maintaining the engine’s performance and efficiency.

N14 CELECT PLUS Engine

In the N14 CELECT PLUS engine, the Air Compressor Brace plays a pivotal role in maintaining the structural integrity of the air compressor. This engine, known for its robust design and high performance, relies on precise components to operate effectively. The brace ensures that the air compressor remains securely fastened, preventing any unwanted movement that could lead to performance issues or mechanical failures.

The installation of this part is crucial for the overall health of the engine, as it helps in evenly distributing the forces exerted on the air compressor during operation. This not only enhances the longevity of the air compressor but also contributes to the engine’s overall reliability and efficiency.

Understanding the Role of 3412324 in Engine Systems

The 3412324 is an essential component in the assembly and operation of various engine systems. Its primary function is to provide structural support and stability to the air compressor, ensuring efficient and reliable performance.

Integration with Mounting Systems

When integrated with mounting systems, the 3412324 plays a significant role in securing the air compressor to the engine frame. This secure attachment is vital for maintaining the compressor’s alignment and reducing vibrations during operation. The brace helps distribute the forces exerted by the compressor, preventing undue stress on the mounting points and enhancing the overall durability of the engine system.

Enhancing Air Compressor Performance

The brace is designed to work in conjunction with the air compressor to optimize its performance. By providing a stable platform, the brace allows the compressor to operate with minimal movement, which is essential for consistent air delivery. This stability is particularly important in high-performance engines where precise air-fuel ratios are necessary for optimal combustion.

Reducing Operational Stress

In addition to supporting the compressor, the 3412324 helps in reducing operational stress on connected components. By absorbing and dispersing vibrations, the brace protects other engine parts from wear and tear, contributing to the longevity of the entire system. This is especially beneficial in environments where the engine is subjected to frequent starts and stops or operates under heavy loads.

Facilitating Maintenance and Repairs

The presence of the brace also simplifies maintenance and repair processes. With the compressor securely held in place, technicians can more easily access and service the unit without the risk of it shifting or becoming dislodged. This not only speeds up repair times but also enhances safety during maintenance procedures.

Conclusion

In summary, the 3412324 Air Compressor Brace is a key component that enhances the functionality and reliability of engine systems by providing essential support and stability to the air compressor. Its role in minimizing movement and vibration, enhancing performance, reducing operational stress, and facilitating maintenance and repairs underscores its importance in the operation of commercial trucks.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.