This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Air Compressor Brace, identified by Part #3820726, is a component manufactured by Cummins, a leader in the commercial truck industry. This Cummins part plays a role in the structural integrity and operational efficiency of the air compressor system in commercial trucks. Its design and function are tailored to meet the demanding requirements of heavy-duty applications.

Function and Operation

This part operates as a supportive structure within the truck’s air system. It is designed to secure the air compressor in place, ensuring that it remains stable during operation. This stability is important for the consistent performance of the air compressor, which is responsible for generating the compressed air needed for various truck systems, including brakes, suspension, and auxiliary equipment. By maintaining the compressor’s position, the brace helps in reducing operational stress and potential wear on the compressor and its mounting points.

Key Features

The design of the Air Compressor Brace incorporates several features that enhance its performance and durability. Constructed from high-strength materials, it is built to withstand the vibrations and stresses associated with heavy-duty truck operations. The brace includes precisely engineered mounting points that ensure a secure fit to the truck’s frame and the air compressor. Its construction may also feature unique attributes such as vibration dampening elements or corrosion-resistant coatings, which contribute to its longevity and reliability in various operating conditions 1.

Benefits

The installation of the Air Compressor Brace offers several advantages. It provides improved stability to the air compressor, which can lead to more efficient operation and reduced wear on the compressor and its associated components. The brace also plays a role in minimizing vibrations, which can contribute to a quieter and more comfortable driving experience. Additionally, by supporting the air compressor, the brace contributes to the overall efficiency and longevity of the truck’s air system.

Installation Considerations

When installing this Cummins part, it is important to follow guidelines and best practices to ensure proper fitting and function. Preparatory steps may include cleaning the mounting area and inspecting the air compressor for any signs of damage or misalignment. The use of appropriate tools is recommended to secure the brace in place, and alignment checks should be performed to confirm that the compressor is properly positioned. Attention to these details during installation can help ensure the brace functions as intended.

Maintenance and Troubleshooting

Routine maintenance of the Air Compressor Brace is relatively straightforward but important for its continued performance. Regular inspections should be conducted to check for signs of wear or damage, such as cracks, corrosion, or loose mounting points. Addressing these issues promptly can prevent more significant problems down the line. Troubleshooting common issues may involve checking the alignment of the air compressor, ensuring that the brace is securely fastened, and verifying that there are no obstructions or interferences with its operation.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its diverse product range and the performance of its components, such as the Air Compressor Brace.

Compatibility with Cummins Engines

The Air Compressor Brace part 3820726, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part plays a role in maintaining the structural integrity and operational efficiency of the air compressor system within these engines.

Compatibility with ISM CM570

The ISM CM570 engine benefits from the Air Compressor Brace part 3820726, ensuring that the air compressor remains securely mounted and functions optimally under various operating conditions.

Compatibility with L10 Engines

The L10 CELECT and L10 MECHANICAL engines both utilize the Air Compressor Brace part 3820726. This part is important for maintaining the alignment and stability of the air compressor, contributing to the overall reliability and performance of the engine.

Compatibility with M11 Engines

The M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines are also compatible with the Air Compressor Brace part 3820726. This part ensures that the air compressor is properly supported, enhancing the engine’s efficiency and longevity.

Compatibility with QSM11 CM570

The QSM11 CM570 engine is another model that integrates the Air Compressor Brace part 3820726. This part is important for maintaining the structural integrity of the air compressor system, ensuring consistent performance and reliability.

By ensuring that the air compressor is securely mounted and aligned, the Air Compressor Brace part 3820726 helps maintain the operational efficiency and longevity of these Cummins engines.

Understanding the Role of Part 3820726 Air Compressor Brace in Engine Systems

The part 3820726 Air Compressor Brace is a component in the assembly and operation of various engine systems. Its primary function is to provide structural support and stability to the air compressor, ensuring efficient and reliable performance.

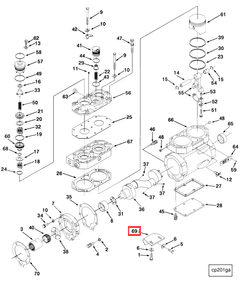

Integration with the Air Compressor

When integrated with the air compressor, the 3820726 brace helps in maintaining the alignment and positioning of the compressor. This is particularly important during the operation of the engine, where vibrations and mechanical stresses are common. The brace absorbs and dissipates these forces, preventing undue strain on the compressor and enhancing its longevity.

Role in the Mounting System

The mounting system of an engine is designed to secure various components in place while allowing for some degree of movement to accommodate operational stresses. The 3820726 brace plays a role here by reinforcing the mounting points of the air compressor. This reinforcement ensures that the compressor remains firmly in place, reducing the risk of detachment or misalignment, which could lead to performance issues or even component failure.

Enhancing Air Flow Efficiency

Efficient air flow is vital for the optimal functioning of any engine system. The 3820726 brace contributes to this by ensuring that the air compressor is securely mounted and operates within its designed parameters. A stable compressor can deliver consistent air pressure, which is essential for various engine functions, including fuel injection, cooling systems, and pneumatic controls 2.

Supporting Overall Engine Stability

Beyond its direct interaction with the air compressor, the 3820726 brace also supports the overall stability of the engine system. By providing a robust connection between the compressor and the engine frame, it helps in maintaining the structural integrity of the entire system. This is particularly beneficial in high-performance or high-stress applications where engine stability is paramount.

Conclusion

In summary, the 3820726 Air Compressor Brace is a key component that enhances the performance, stability, and longevity of engine systems by providing essential support to the air compressor and integrating seamlessly with the mounting system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.