This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

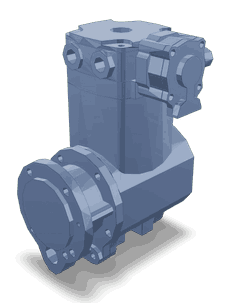

The Cummins 3558132 Air Compressor is a critical component designed for use in commercial trucks. It ensures the efficient operation of various truck systems, particularly those reliant on compressed air. Understanding its function and importance can aid in maintaining and optimizing truck performance.

Basic Concepts of Air Compressors

An air compressor converts power into potential energy stored in pressurized air. This pressurized air is then used to perform work in various systems. In commercial trucks, air compressors are essential for operating systems such as brakes, air suspension, and other pneumatic controls. They work by drawing in air, compressing it, and storing it in a tank until needed 1.

Purpose of the Cummins 3558132 Air Compressor

The Cummins 3558132 Air Compressor provides the necessary compressed air for the braking system, air suspension, and other pneumatic systems. It ensures these systems function correctly by maintaining the required air pressure. This compressor is integral to the safe and efficient operation of the truck, directly influencing the performance of critical systems 2.

Key Features

The Cummins 3558132 Air Compressor is characterized by its robust design and high build quality. It features a durable construction that can withstand the demanding conditions of commercial truck operations. Unique attributes of this model include its efficient compression ratio and reliable performance under varying load conditions 3.

Benefits

Using the Cummins 3558132 Air Compressor offers several advantages. It contributes to improved performance of the truck’s systems, enhances reliability by ensuring consistent air pressure, and increases efficiency through its optimized design. These benefits help in maintaining the overall functionality and safety of the truck 4.

Installation and Integration

Proper installation of the Cummins 3558132 Air Compressor involves several steps to ensure it integrates seamlessly into the truck’s system. This includes checking for compatibility with the truck’s make and model, following the manufacturer’s guidelines for installation, and ensuring all connections are secure. Consideration should be given to the compressor’s location to avoid interference with other components and to facilitate easy access for maintenance 5.

Maintenance and Care

Routine maintenance of the Cummins 3558132 Air Compressor is crucial for its longevity and optimal performance. This includes regular checks for leaks, ensuring the compressor is free from debris, and monitoring the air pressure levels. Scheduled servicing, such as oil changes and filter replacements, should be performed according to the manufacturer’s recommendations 6.

Troubleshooting Common Issues

Common problems with the Cummins 3558132 Air Compressor may include insufficient air pressure, unusual noises, or leaks. Troubleshooting these issues involves checking for blockages in the air lines, inspecting the compressor for damage, and ensuring all connections are tight. Addressing these problems promptly can prevent more serious issues and maintain the compressor’s efficiency 7.

Performance Enhancements

There are potential upgrades or modifications that can be made to the Cummins 3558132 Air Compressor to enhance its performance. These may include installing a higher capacity air tank, upgrading the filtration system, or optimizing the compressor’s settings to better match the truck’s operational demands. Such enhancements can lead to improved efficiency and reliability 8.

Safety Considerations

When working with the Cummins 3558132 Air Compressor, it is important to follow safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the compressor is turned off and depressurized before performing maintenance, and adhering to all safety instructions provided by the manufacturer. These precautions help ensure safe operation and maintenance of the compressor 9.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the industry. The company’s mission is to make people’s lives better by powering a more prosperous world 10.

Cummins AIR COMPRESSOR Part 3558132 Compatibility

The Cummins AIR COMPRESSOR part number 3558132 is designed to integrate seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This part is particularly compatible with the following engines:

- N14 CELECT PLUS

When installed in the N14 CELECT PLUS engine, the AIR COMPRESSOR part 3558132 plays a crucial role in maintaining the engine’s air supply system. It ensures that the engine receives the necessary compressed air for various functions, including starting and operation. The design and engineering of this part are tailored to meet the specific requirements of the N14 CELECT PLUS, ensuring a perfect fit and efficient performance.

The AIR COMPRESSOR part 3558132 is engineered to withstand the demanding conditions of engine operation, providing durability and consistent performance over time. Its integration with the N14 CELECT PLUS engine is straightforward, thanks to its precise manufacturing and compatibility with the engine’s design specifications. This ensures that the engine can operate smoothly and efficiently, with minimal maintenance requirements 11.

Understanding the Integration of Part 3558132 Air Compressor in Engine Systems

The part 3558132 air compressor is a critical component in various engine systems, primarily responsible for enhancing engine performance and efficiency. Its role is multifaceted, contributing to several key aspects of engine operation.

Role in Fuel Injection Systems

In fuel injection systems, the air compressor ensures a steady supply of pressurized air. This pressurized air mixes with fuel in the injectors, creating a fine mist that combusts more efficiently. The result is improved fuel economy and reduced emissions 12.

Contribution to Turbocharging

When integrated into turbocharged engines, the air compressor works in tandem with the turbocharger. It provides additional air pressure, allowing the turbocharger to operate more effectively. This synergy leads to increased power output and better throttle response 13.

Support in Emission Control Systems

The air compressor also plays a part in emission control systems. By supplying pressurized air to the exhaust gas recirculation (EGR) system, it helps in reducing nitrogen oxides (NOx) emissions. This is achieved by diluting the intake charge with exhaust gases, which lowers the combustion temperature 14.

Enhancement of Brake Systems

In brake systems, particularly those utilizing air brakes in commercial vehicles, the air compressor is vital. It builds and maintains the air pressure required for the brake system to function correctly. This ensures reliable and safe braking performance under various conditions 15.

Assistance in Climate Control Systems

For climate control systems, the air compressor contributes to the efficiency of the air conditioning system. It provides the necessary pressure for the refrigerant to cycle through the system, ensuring effective cooling inside the vehicle 16.

Impact on Engine Lubrication

The air compressor indirectly supports the engine lubrication system. By maintaining optimal air pressure, it ensures that the engine operates within its designed parameters, reducing wear and tear on moving parts and prolonging the life of the lubrication system 17.

Integration with Engine Management Systems

Modern engine management systems rely on data from various sensors, including those monitoring air pressure. The air compressor ensures consistent air pressure, allowing the engine management system to make accurate adjustments for optimal performance and efficiency 18.

Conclusion

In summary, the part 3558132 air compressor is a versatile component that enhances multiple aspects of engine systems, from fuel injection and turbocharging to emission control and climate management. Its integration is key to achieving superior engine performance and reliability.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

D. K. Singh, Dictionary of Mechanical Engineering, Springer Nature, 2024.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, McGraw-Hill, 2008.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, McGraw-Hill, 2008.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., Company Overview, Official Website.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, McGraw-Hill, 2008.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩ -

Cummins Inc., General Information, Bulletin Number 3666397-03, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.